Superfine 10B-rich titanium diboride powder and preparation method thereof

The technology of titanium diboride and titanium dioxide is applied in the field of 10B-rich titanium diboride powder and its preparation, which can solve the problem of high cost of raw materials, and achieve the effects of stable product components, strong operability and fast synthesis speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

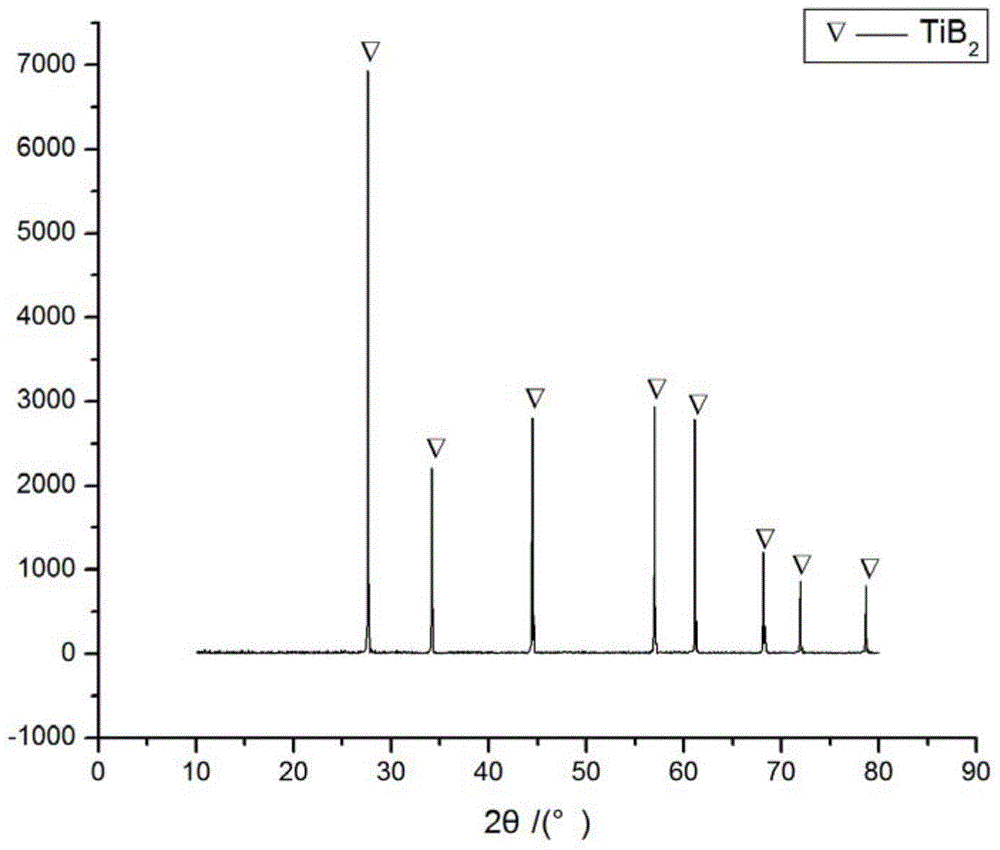

Embodiment 1

[0040] a super fine 10 The preparation method of B titanium diboride powder comprises steps as follows:

[0041] (1) will 10 B abundance 85% rich10 B boron carbide powder (average particle size 10-30μm) 25.5kg, anatase titanium dioxide (average particle size 20-40μm) 64kg, carbon black (average particle size 10-30μm) 10kg and calcium oxide (average particle size (10-20μm in diameter) 0.5kg is mixed in a dry color mixer for 40min;

[0042] (2) Transfer the dry mixed raw materials to a medium frequency induction sintering furnace, raise the temperature to 2000°C in an argon atmosphere, hold the temperature for 27 hours, and heat up at a rate of 10°C / min;

[0043] (3) The calcined product was wet-milled with a sand mill for 7 hours, filtered and dried for 15 hours to obtain titanium diboride powder with a particle size of 0.6 μm. The main crystal phase is TiB 2 phase, with a purity of 98%, 10 B abundance is 85%.

Embodiment 2

[0045] a super fine 10 The preparation method of B titanium diboride powder comprises steps as follows:

[0046] (1) will 10 B abundance 65% rich 10 B boron carbide powder (average particle size 10-30μm) 30kg, anatase titanium dioxide (average particle size 20-40μm) 64kg, carbon black (average particle size 10-30μm) 8kg and calcium oxide (average particle size 10-20μm) 0.5kg in a dry color mixer for 35min;

[0047] (2) Transfer the dry-mixed raw materials to an intermediate frequency induction sintering furnace, raise the temperature to 1850°C in an argon atmosphere, hold the temperature for 22 hours, and heat up at a rate of 8°C / min;

[0048] (3) The calcined product was wet ball-milled with a sand mill for 6 hours, filtered and dried for 10 hours to obtain titanium diboride powder with a particle size of 0.8 μm. The main crystal phase is TiB 2 phase, with a purity of 96%, 10 B abundance is 65%.

Embodiment 3

[0050] a super fine 10 The preparation method of B titanium diboride powder comprises steps as follows:

[0051] (1) will 10 B abundance 80% rich 10 B boron carbide powder (average particle size 10-30μm) 28kg, anatase titanium dioxide (average particle size 20-40μm) 64kg, carbon black (average particle size 10-30μm) 9kg and calcium oxide (average particle size 10-20μm) 0.5kg in the dry color mixer for 30min;

[0052] (2) Transfer the dry-mixed raw materials to an intermediate frequency induction sintering furnace, raise the temperature to 1950°C in an argon atmosphere, hold the temperature for 24 hours, and heat up at a rate of 10°C / min;

[0053] (3) The calcined product was wet-milled with a sand mill for 7 hours, filtered and dried for 20 hours to obtain titanium diboride powder with a particle size of 0.7 μm. The main crystal phase is TiB 2 phase, with a purity of 97%, 10 B abundance is 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com