Aqueous epoxy modified alkyd resin and preparation method and application thereof

A water-based epoxy and alkyd resin technology, used in coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of inconspicuous results and few discussions on chemical modification of water-soluble alkyd resins. Strong adhesion, high hardness, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

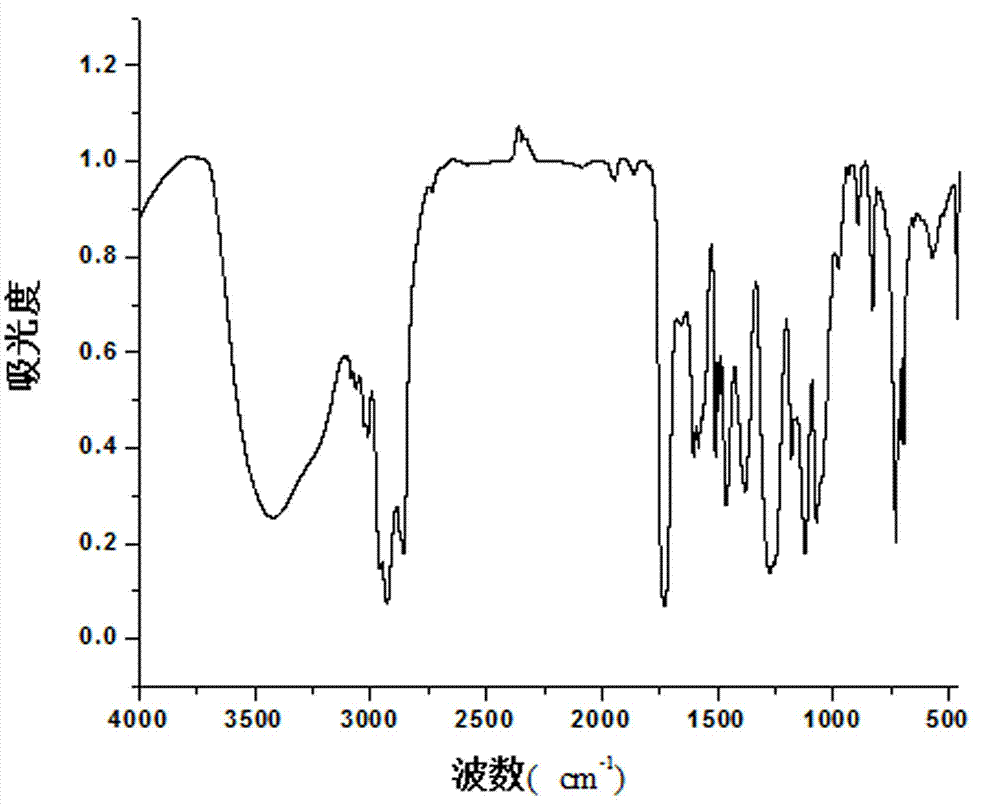

Image

Examples

Embodiment 1

[0049] 1. Formula of waterborne epoxy modified alkyd resin

[0050] The water-based epoxy modified alkyd resin is prepared from the following raw materials: 270g of linseed oil fatty acid, 100g of epoxy resin, 40mg of zinc oxide, 60g of benzoic acid, 110g of pentaerythritol, 100g of phthalic anhydride, 50g of trimellitic anhydride, Maleic anhydride oil 50g, ethylene glycol monobutyl ether 260g. Maleic anhydride oil is prepared by mixing 9g of maleic anhydride with 41g of flax oil.

[0051] 2. Preparation method of water-based epoxy modified alkyd resin

[0052] ①Add 270g of linseed oil fatty acid and 100g of epoxy resin into the reaction kettle, start stirring, and raise the temperature to 120°C under stirring; after stopping stirring, add 40mg of zinc oxide, continue stirring, raise the temperature to 180°C, and keep the esterification reaction for 2.5h .

[0053] ②Add 60g of benzoic acid, 100g of phthalic anhydride, 110g of pentaerythritol and 20g of xylene in the reactio...

Embodiment 2

[0061] 1. Formula of waterborne epoxy modified alkyd resin

[0062] Water-based epoxy-modified alkyd resin is prepared from the following raw materials: 280g of sesame oil, 90g of epoxy resin, 27mg of zinc oxide, 50g of benzoic acid, 130g of trimethylolpropane, 80g of maleic anhydride, and 60g of trimellitic anhydride , maleic anhydride oil 40g, ethylene glycol monobutyl ether 280g. Maleic anhydride oil is prepared by mixing 6g of maleic anhydride and 34g of linseed oil.

[0063] 2. Preparation method of water-based epoxy modified alkyd resin

[0064] ①Add 280g of flax oil and 90g of epoxy resin into the reaction kettle, start stirring, and raise the temperature to 115°C under stirring; after stopping the stirring, add 27mg of zinc oxide, continue stirring, raise the temperature to 175°C, and keep the esterification reaction for 2.2h.

[0065] ②Add 50g of benzoic acid, 80g of maleic anhydride, 130g of trimethylolpropane and 25g of xylene into the reaction kettle. The reacti...

Embodiment 3

[0073] 1. Formula of waterborne epoxy modified alkyd resin

[0074] The water-based epoxy modified alkyd resin is prepared from the following raw materials: 290g of linseed oil fatty acid, 110g of epoxy resin, 58mg of zinc oxide, 55g of benzoic acid, 120g of pentaerythritol, 90g of isophthalic acid, 40g of trimellitic anhydride, 60 g of anhydride oil and 250 g of ethylene glycol monobutyl ether. Maleic anhydride oil is prepared by mixing 12g of maleic anhydride and 48g of flax oil.

[0075] 2. Preparation method of water-based epoxy modified alkyd resin

[0076] ①Add 290g of linseed oil fatty acid and 110g of epoxy resin into the reaction kettle, start stirring, and raise the temperature to 125°C under stirring; after stopping stirring, add 58mg of zinc oxide, continue stirring, raise the temperature to 185°C, and keep the esterification reaction for 2.0h .

[0077] ②Add 55g of benzoic acid, 90g of isophthalic acid, 120g of pentaerythritol and 30g of xylene into the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com