Winding method of high-frequency transformer

A high-frequency transformer and winding method technology, applied in the field of transformers, can solve the problems of output winding voltage drift, difficult to control, poor coupling of secondary windings, etc., to achieve good electromagnetic coupling, improve performance, and solve the effects of voltage drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

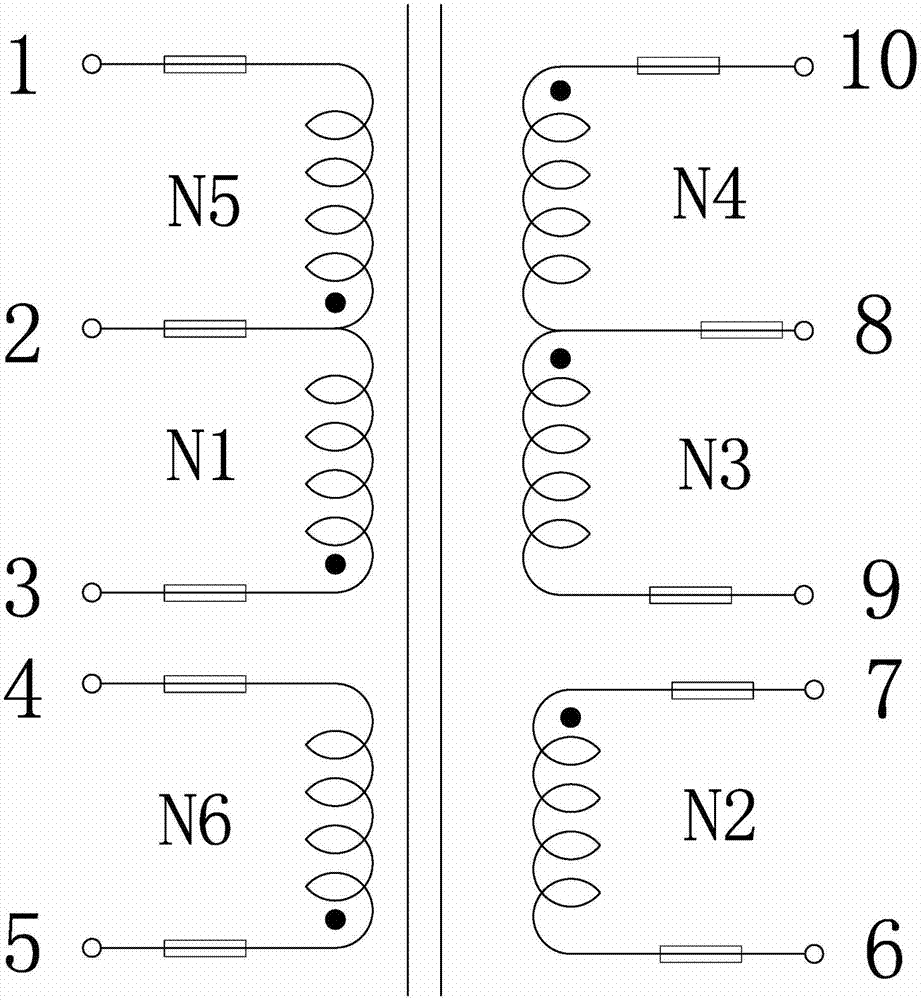

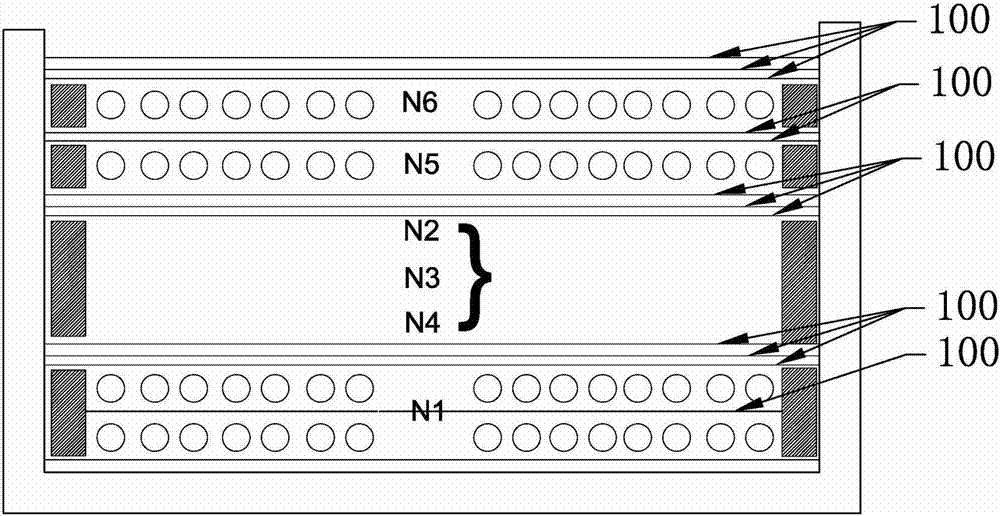

[0037] A winding method of a high-frequency transformer in this embodiment, the high-frequency transformer includes a skeleton, an iron core, a primary winding and a secondary winding, the iron core is arranged on the skeleton, and the primary winding and the secondary winding are all wound on the iron core, such as figure 1 and figure 2 As shown, the winding method of its secondary winding includes the following steps:

[0038] (1) The winding N2 starts two strands at the starting end 7 of the skeleton, the winding N3 starts one strand at the starting end 8 of the skeleton, and the winding N4 starts one strand at the starting end 10 of the skeleton;

[0039] (2) Twist the four strands of (1) into a twisted strand;

[0040] (3) After wrapping the twisted wire of (2) evenly and densely around the winding groove of the skeleton for three layers, hang the end of the strand of winding N3 on Hanging on the 8 ends of the starting line of the skeleton;

[0041] (4) Wind the two s...

Embodiment 2

[0047] A winding method for a high-frequency transformer. The other structures of this embodiment are the same as those of Embodiment 1, except that the primary winding includes winding N1, winding N5 and auxiliary winding N6, and the windings of the primary winding and the secondary winding are sequentially The sequence is winding N1, secondary winding, winding N5 and auxiliary winding N6.

[0048] The winding method between the primary winding and the secondary winding is called the sandwich winding method, which has the following advantages: 1. It can reduce the leakage inductance of the transformer, and the benefit of reducing the leakage inductance is that the voltage spike will be reduced, making the MOSFET (gold oxide Half field effect transistor Metal-Oxide-Semiconductor Field-Effect Transistor) voltage stress reduction;

[0049] 2. Improve EMI (electromagnetic interference): the common mode interference current caused by MOSFET and heat sink can also be reduced, there...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com