Adsorbent for removing benzothiophene in diesel and preparation method thereof

A benzothiophene and adsorbent technology, which is applied in the field of adsorbents for highly selective removal of benzothiophene in diesel oil, can solve the problems of affecting the service life of the adsorbent, loss of cerium ions, etc., achieves good hydrothermal stability, reduces Loss, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

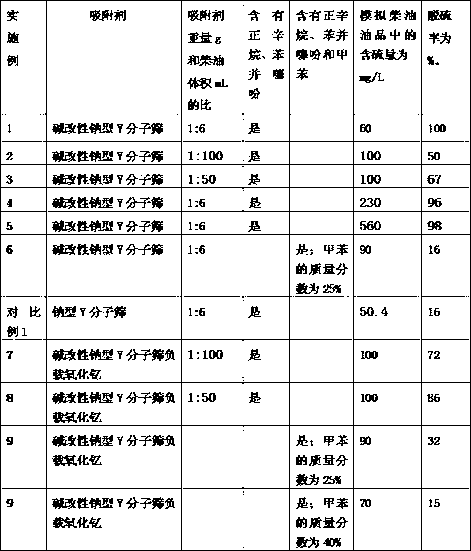

Embodiment 1

[0021] Add 2 g of sodium-type Y molecular sieves to 10 mL, 0.09 mol / L NaOH solution, put it into a crystallization kettle and mix evenly, react at 120 °C for 10 hours, vacuum filter, wash the solid matter, and wash with distilled water until it is washed. The pH value of the liquid is 7, put it into an oven at 100°C and dry it, then raise the temperature to 540°C in a muffle furnace at a rate of 5°C / min, and maintain this temperature for 4 hours to obtain an alkali-modified sodium Y molecular sieve, which is used as a removal Adsorbent for benzothiophene in diesel fuel.

[0022] Desulfurization: Weigh 1 g of alkali-modified sodium Y molecular sieve adsorbent, 6 mL of simulated diesel oil containing n-octane and benzothiophene, put the two in a batch kettle, and react at 50 ° C for 1 hour to simulate The sulfur content of the diesel oil is 60 mg / L, the sulfur content of the simulated diesel oil after desulfurization is 0 mg / L, and the desulfurization rate is 100%.

Embodiment 2

[0026] The concentration of NaOH solution was 0.2 mol / L, and the reaction was carried out at 80° C. for 20 hours. The rest was the same as in Example 1 to obtain an alkali-modified sodium Y molecular sieve, which was used as an adsorbent for removing benzothiophene from diesel.

[0027] Desulfurization: Weigh 0.06 g of alkali-modified sodium Y molecular sieve adsorbent and soak it at 80° C. for 4 hours, and the other conditions are the same as in Example 1. The sulfur content of the simulated diesel oil is 100 mg / L, the sulfur content of the desulfurized oil is 50 mg / L, and the desulfurization rate is 50%.

Embodiment 3

[0029] The concentration of the NaOH solution was 0.01 mol / L, the reaction temperature was 170° C., and the rest was the same as in Example 1 to obtain an alkali-modified sodium Y molecular sieve, which was used as an adsorbent for removing benzothiophene from diesel.

[0030] Desulfurization: Weigh 0.12 g of alkali-modified sodium-type Y molecular sieve adsorbent, soak for 2 hours, and the rest of the conditions are the same as in Example 1. The sulfur content of the simulated diesel oil is 100 mg / L, the sulfur content of the desulfurized oil is 33 mg / L, and the desulfurization rate is 67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com