Carbon dioxide gas shielded welding flux-cored wire

A technology of gas shielded welding and flux-cored welding wire, applied in welding medium, welding equipment, welding/cutting medium/material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

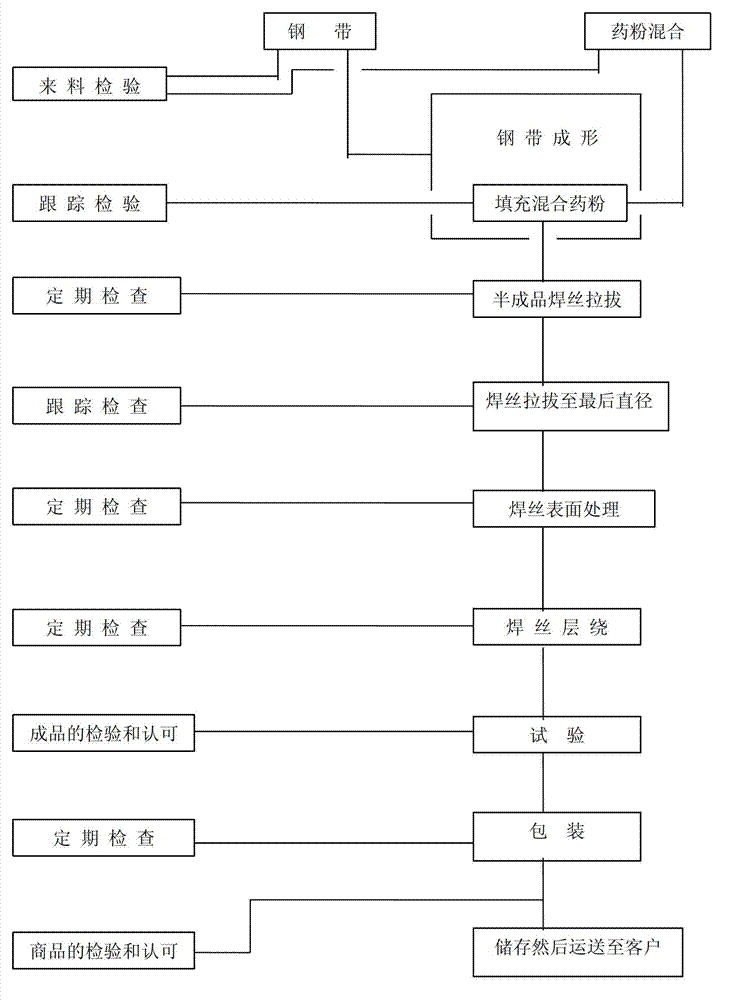

Method used

Image

Examples

Embodiment 1

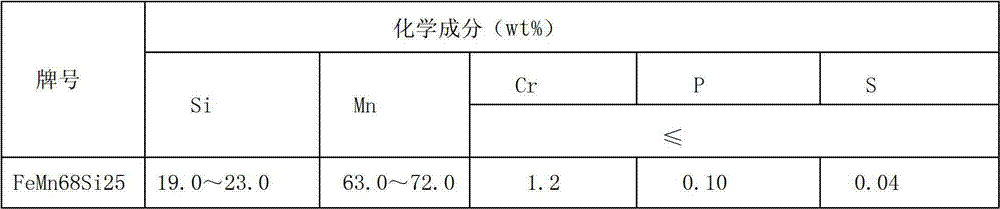

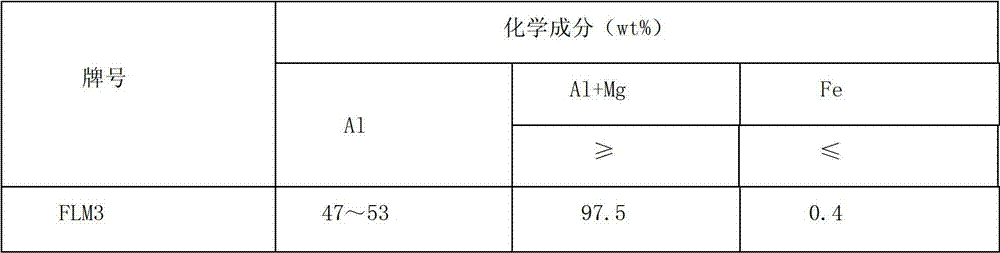

[0094] Select a steel strip with a nominal thickness of 0.60mm and a nominal width of 1000mm for flux cored wire, and use a forming machine to roll it into a U-shaped groove. Take 1000 grams of submerged arc welding flux-cored wire as an example: take 170 grams of rutile, 150 grams of silicon-manganese alloy, 250 grams of iron powder, 90 grams of nickel powder, 180 grams of metal chromium, 30 grams of aluminum-magnesium alloy, 70 grams of ferromolybdenum, vanadium 60 grams of iron. Put all the raw materials into the mixer and mix for 45 minutes, then add them to the U-shaped channel steel belt, the filling rate is 35%; close the U-shaped channel so that the drug core powder is wrapped in it, and then draw and reduce the diameter through the wire drawing machine , finally making the diameter of the wire reach 3.2mm.

[0095] 1. Test method:

[0096] (1) Chemical composition test

[0097] After welding the welding wire to the surfacing welding test plate, take the welding con...

Embodiment 2

[0106] Select a steel strip with a nominal thickness of 0.50mm and a nominal width of 900mm for flux-cored wire cold-rolled steel strip, and use a forming machine to roll it into a U-shaped groove. Take 1000 grams of submerged arc welding flux-cored wire as an example: take 120 grams of rutile, 140 grams of silicon-manganese alloy, 300 grams of iron powder, 120 grams of nickel powder, 20 grams of metal chromium, 40 grams of aluminum-magnesium alloy, 40 grams of ferromolybdenum, vanadium Iron 40 grams. Put all the raw materials into the mixer and mix for 45 minutes, then add them to the U-shaped channel steel belt, the filling rate is 37%; close the U-shaped channel so that the drug core powder is wrapped in it, and then draw and reduce the diameter through the wire drawing machine , finally making the diameter of the wire reach 1.6mm.

Embodiment 3

[0108] Select a steel strip with a nominal thickness of 0.80mm and a nominal width of 1020mm for flux-cored wire cold-rolled steel strip, and use a forming machine to roll it into a U-shaped groove. Take 1000 grams of submerged arc welding flux-cored wire as an example: take 250 grams of rutile, 200 grams of silicon-manganese alloy, 150 grams of iron powder, 50 grams of nickel powder, 100 grams of metal chromium, 50 grams of aluminum-magnesium alloy, 100 grams of ferromolybdenum, vanadium Iron 100 grams. Put all the raw materials into the mixer and mix for 45 minutes, then add them to the U-shaped channel steel belt, the filling rate is 37%; close the U-shaped channel so that the drug core powder is wrapped in it, and then draw and reduce the diameter through the wire drawing machine , finally making the diameter of the wire reach 1.6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com