Preparation method of strontium carbonate with high purity

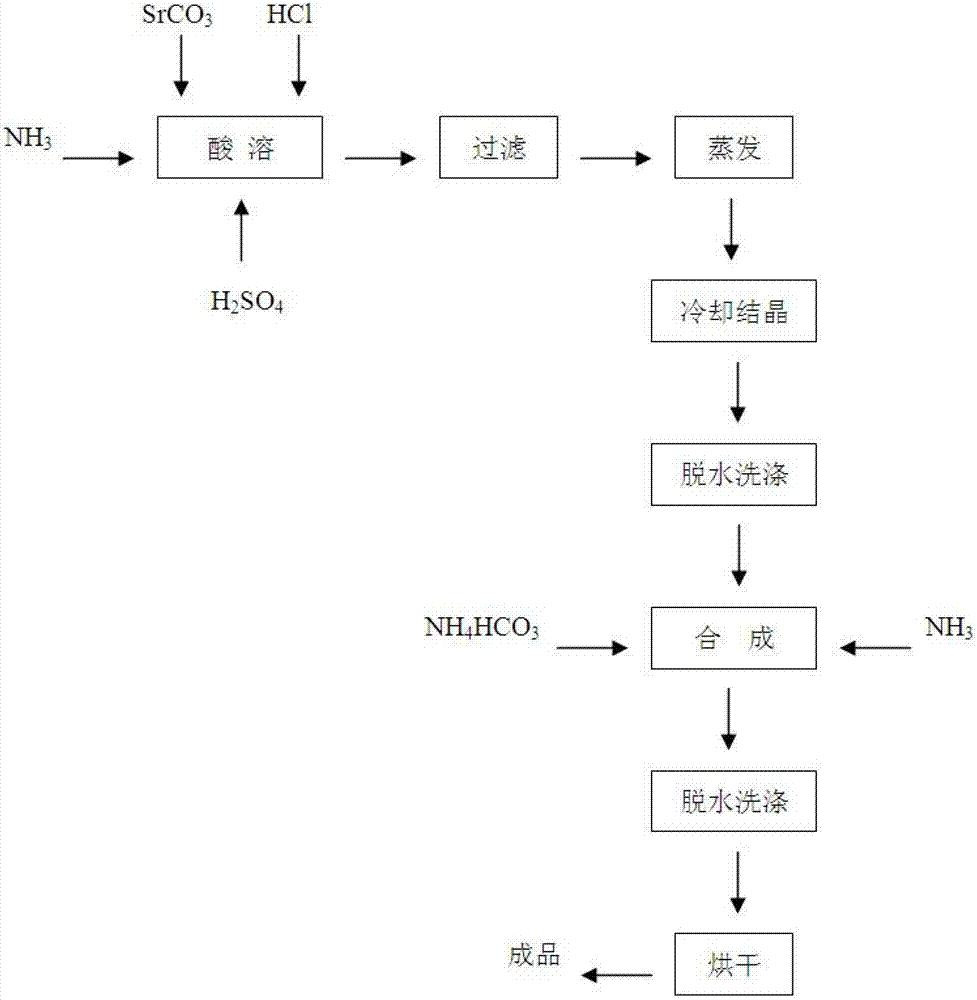

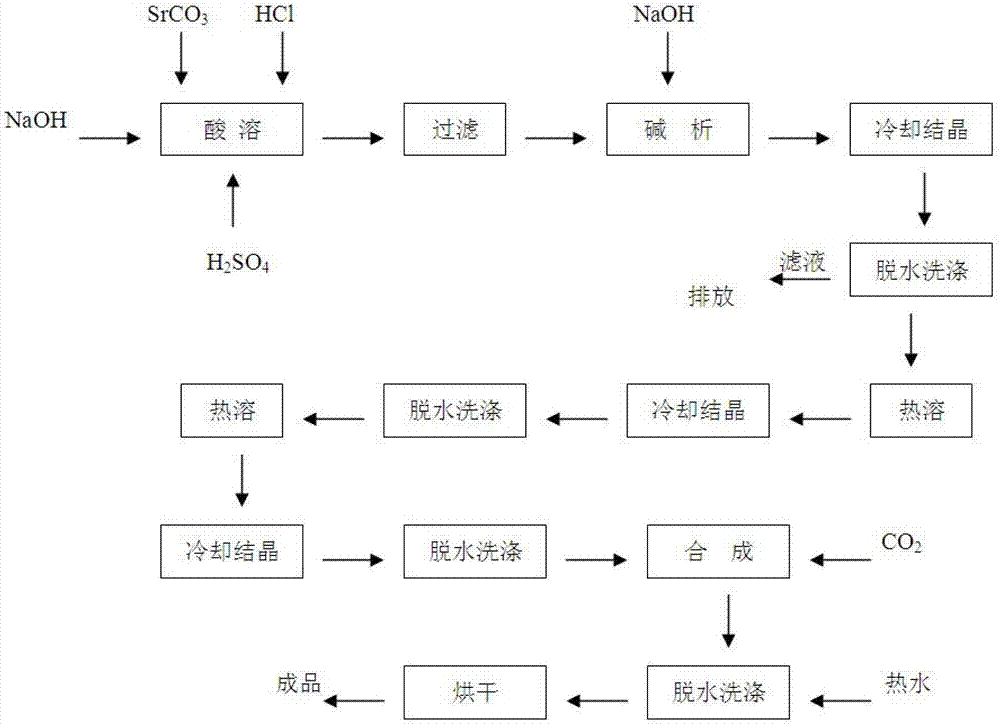

A technology of high-purity strontium carbonate and high-purity water, which is applied in the direction of calcium carbonate/strontium/barium, calcium/strontium/barium sulfate, etc., can solve the difficulty of handling ammonium chloride solution, the difficulty of chloride washing, and the difficulty of synthesizing particle size and other problems, to achieve the effect of easy product quality, high utilization rate and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

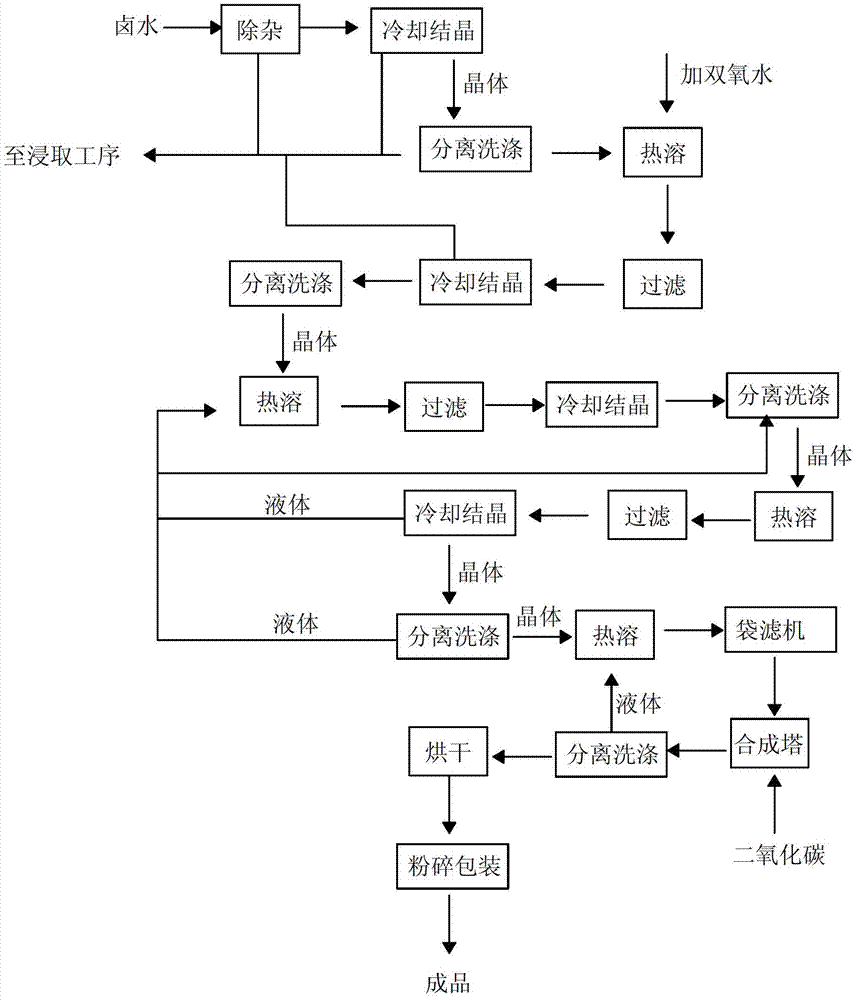

[0033] Embodiment: the preparation method of high-purity strontium carbonate of the present invention, as image 3 As shown, it includes the following steps: (1) first remove impurities from the brine (the main component is strontium sulfide solution) in the strontium sulfide leaching process, and then cool and crystallize (the main component of the crystal is strontium hydroxide octahydrate); (2) put The crystals are separated and washed, and the washing liquid is returned to the leaching process; (3) The first recrystallization: the crystals are dissolved in high-purity water at 90 ° C, and every 20 grams of strontium hydroxide octahydrate crystals are dissolved in 100 ml of high-purity water, and hydrogen peroxide is added at the same time Oxidize sulfur ions in various valence states in the solution, the molar ratio of hydrogen peroxide to sulfur ions in the solution is 1:1; stir for 30 minutes, filter, the filter residue is mainly strontium sulfate precipitate, after treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com