Preparation method of inorganic-organic composite coagulant

A composite flocculant, organic technology, applied in the field of environment and chemistry, can solve the problem of high dosage, achieve the effect of low dosage, good treatment effect, and large molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

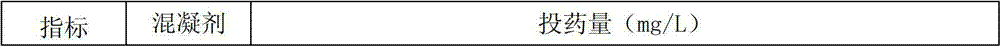

Embodiment 1

[0027] The preparation method of polyaluminum chloride-polydimethyldiallylammonium chloride composite flocculant, the steps are as follows:

[0028] Weigh 44.17g of AlCl 3 ·6H 2 O solid in a beaker, add distilled water to dissolve, and make AlCl 3 solution;

[0029] Weigh 19.63g of anhydrous Na 2 CO 3 , to AlCl under stirring conditions 3 Add Na to the solution 2 CO 3 , after the foam disappears, add 6.25g of polydimethyldiallylammonium chloride, then continue to stir at room temperature for 3h, and distill the volume to 500mL with distilled water to obtain an alkalinity of 2.0, Al 2 o 3 Polyaluminum chloride-polydimethyldiallylammonium chloride composite flocculant with a content of 18.89g / L.

Embodiment 2

[0031] As in the preparation method described in Example 1, the difference is that 3.12 g of polydimethyldiallyl ammonium chloride is added, and then stirring is continued at room temperature for 3 h, and then the volume is adjusted to 500 mL with distilled water to obtain an alkalized Degree 2.0, Al 2 o 3 Polyaluminum chloride-polydimethyldiallylammonium chloride composite flocculant with a content of 18.89g / L.

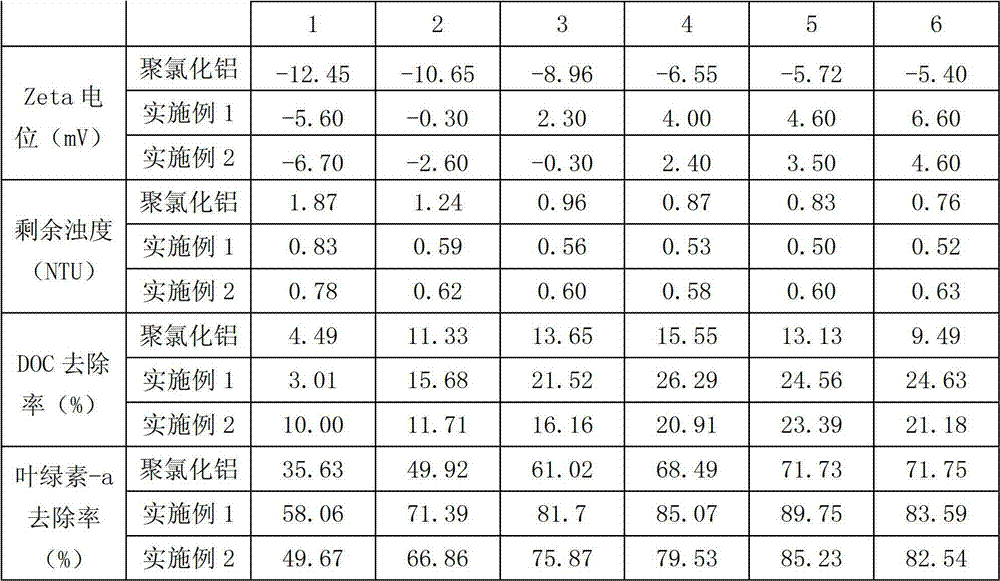

Embodiment 3

[0033] The preparation method of polyferric chloride-polydimethyldiallylammonium chloride composite flocculant, the steps are as follows:

[0034] Weigh 23.88g of FeCl 3 Put the solid in a beaker, add distilled water to dissolve, and obtain FeCl 3 solution;

[0035] Weigh 2.36g of anhydrous Na 2 CO 3 , to FeCl under agitation 3 Add Na to the solution 2 CO 3, after the foam disappears, according to FeCl 3 Medium Fe element and NaH 2 PO 4 The molar ratio of the P element in the medium is 25:2, adding NaH 2 PO 4 , add 6.25g of polydimethyldiallyl ammonium chloride, then continue to stir at room temperature for 3h, use distilled water to make up to 500mL, and obtain a degree of alkalinity of 0.5, Fe 2 o 3 Polymerized ferric chloride-polydimethyldiallylammonium chloride composite flocculant with a content of 13.33g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com