Method for backside-contacting a silicon solar cell, and silicon solar cell with backside-contacting

A silicon solar cell and backside technology, applied in the field of solar cells, can solve the problems of surface damage of silicon chips, degradation of electrical properties of solar cells, etc., and achieve the effects of reducing the risk of chip breakage, preventing damage, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

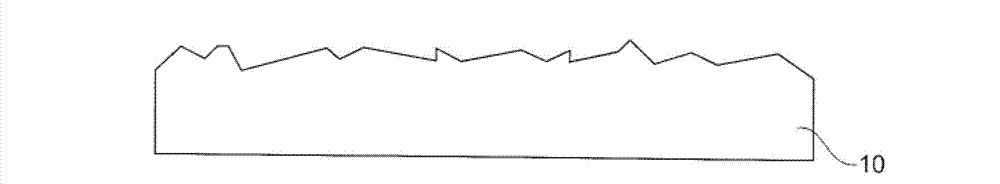

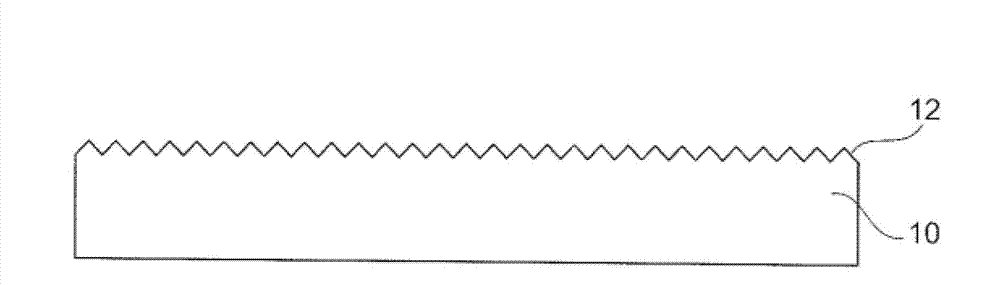

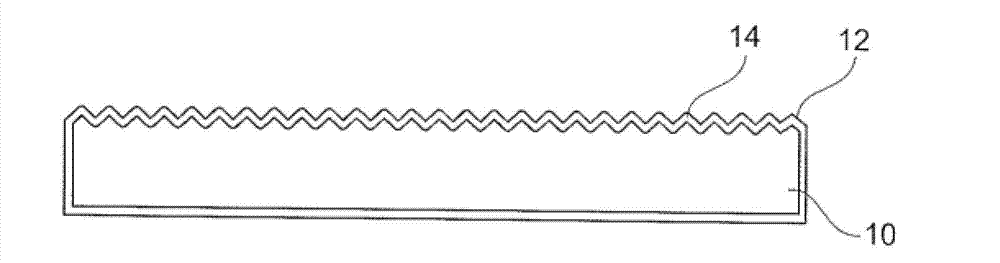

[0024] In the following, combined with Figure 1-8 To explain a possible configuration of a cheap and simple way of a method for fabricating a silicon solar cell with a back contact comprising a back surface field. Figure 9 Rear view of a silicon solar cell showing possible configurations with contact fields for back contact. Figure 10 A cutaway view showing a solar module with two solar cells connected in series. Figure 11-13 and Figure 14-17 Two further possible configurations of the method for manufacturing a silicon solar cell with an inexpensive and easily configurable back contact comprising a back surface field are respectively shown. All figures are schematic representations only and not drawn to scale.

[0025] In the method according to the invention for arranging a rear contact on a silicon solar cell, methods known from the field of semiconductors and solar technology are used. In addition, materials commonly used in the field of semiconductor and solar tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com