Preparation method of low-biogenic amine soy sauce

A biogenic amine and soy sauce technology, applied in food preparation, food science, application and other directions, can solve the problems of reducing the content of biogenic amines in soy sauce, heavy acetic acid odor, rusting of iron equipment, etc. The effect of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) After 1 mass part of soybean meal is steamed, it is mixed with 0.2 mass part of flour, 0.003 mass part of glycine, and 0.001 mass part of citric acid, inoculated with 0.02% (w / w) weight of soybean meal aspergillus oryzae refined, and koji is obtained. song;

[0022] (2) Using the high-salt dilute soy sauce brewing method (GB18186-2000) after 80 days of fermentation, squeezing and filtering to obtain the soy sauce stock solution.

[0023] In step (1), the cooking conditions are: 110°C, cooking for 20 minutes; the koji making conditions: the culture temperature is 28°C, the humidity is 95%, and the culture time is 72 hours.

[0024] The blank in Table 1 means that glycine and citric acid are not added.

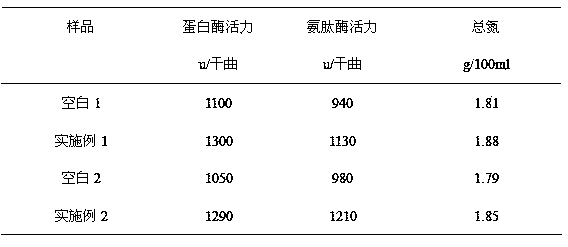

[0025] Table 1 shows the content of biogenic amines in soy sauce crude oil prepared by different fermentation processes. Table 2 shows the effects of different koji making processes on the activity of soy sauce daqu enzyme and crude oil. It can be seen from Table 1 that the...

Embodiment 2

[0031] (1) After 1 part by mass soybeans are steamed, mixed with 1 part by mass of flour, 0.008 parts by mass of glycine, and 0.002 parts by mass of citric acid, inoculated with 0.04% (w / w) of soybean weight of Aspergillus oryzae koji extract, and koji is obtained. song;

[0032] (2) The high-salt dilute state soy sauce brewing method (GB18186-2000) is fermented for 90 days, then pressed and filtered to obtain the soy sauce stock solution.

[0033] The cooking conditions in step (1) are: 125°C, cooking for 5 minutes; the koji making conditions: the culture temperature is 36°C, the humidity is 95%, and the culture time is 44 hours.

[0034] Blank 2 is the sample without adding glycine and citric acid.

Embodiment 3

[0036] (1) After 1 mass part of soybean meal is steamed, it is mixed with 0.4 mass part of flour, 0.004 mass part of glycine, and 0.001 mass part of citric acid, inoculated with 0.08% (w / w) weight of soybean meal aspergillus oryzae refined, and koji is obtained. song;

[0037] (2) The high-salt dilute state soy sauce brewing method (GB18186-2000) is fermented for 120 days, then pressed and filtered to obtain the soy sauce stock solution.

[0038] In step (1), the cooking conditions are: 120°C, cooking for 10 minutes; the koji making conditions are: the culture temperature is 30°C, the humidity is 85%, and the culture time is 48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com