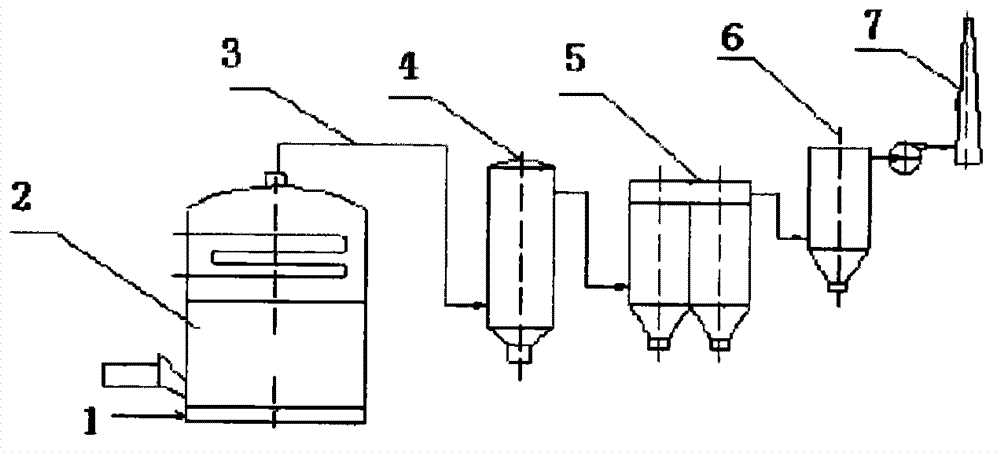

Removal device of tetrachlorodibenzo-p-dioxin in refuse burning system

A technology of waste incineration and dioxin, which is applied in the field of dioxin removal device in waste incineration system, can solve the problems of high price of activated carbon molecular sieve and low dioxin adsorption efficiency, and achieve good adsorption and absorption capacity, Effective adsorption, wide source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Flue gas flow: 82500m 3 / h, dioxin concentration: 5ng / m 3

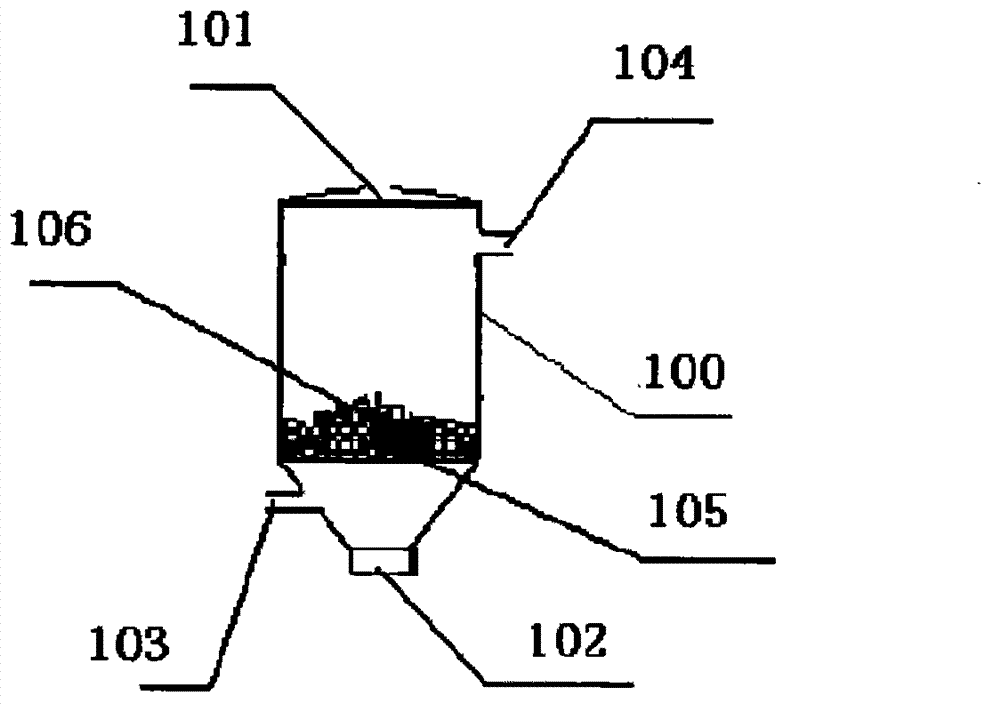

[0026] Semi-coke molecular sieve refers to the above-mentioned lignite semi-coke and kaolin with a particle size of less than 200 meshes as raw materials. The mass ratio of lignite semi-coke to kaolin is 10:1, and a spherical molecular sieve with a diameter of 5mm is prepared by extrusion, and heated at 620 ° C. Prepared by roasting for 3h.

[0027] First, through the semi-coke molecular sieve inlet on the top of the flue gas purification tower, 30kg of the above-mentioned semi-coke molecular sieves are evenly arranged on the substrate, and the flue gas passes through the above-mentioned semi-coke molecular sieve through the waste incineration flue gas inlet to absorb dioxins in the waste incineration flue gas and removal, the dioxin content in the flue gas is reduced to 0.05ng / m at the outlet of waste incineration flue gas 3 , and then discharged through the chimney 5. The adsorbed semi-coke molecular siev...

Embodiment 2

[0029] Compared with Example 1, the only difference is that the semi-coke molecular sieve is a modified semi-coke molecular sieve, and the modified semi-coke molecular sieve is obtained through the following steps: first, the semi-coke molecular sieve is placed in 1.5mol / L NaOH The solution was crystallized at 90°C for 3h, washed with water to pH = 8, and then placed in 90°C, 0.5mol / L CaCl 2 Exchange in the solution for 2 hours. After the exchanged samples were washed and dried, they were placed in a 1mol / L oxalic acid solution at 80°C for 2 hours. After washing and drying, they were activated at 500°C for 2 hours. At the outlet of waste incineration flue gas, the content of dioxin in the flue gas is reduced to 0.03ng / m 3 .

Embodiment 3

[0031] Compared with Example 1, the difference is only in the described semi-coke molecular sieve. The semi-coke molecular sieve refers to the above-mentioned lignite semi-coke and kaolin with a particle size below 200 meshes as raw materials, and the mass ratio of lignite semi-coke to kaolin is 10: 1. Prepare a spherical molecular sieve with a diameter of 5mm by extrusion, and bake it at 550°C for 3 hours. At the outlet of waste incineration flue gas, the content of dioxin in the flue gas is reduced to 0.06ng / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com