Chicken manure/pig manure mixed fermentation fertilizer and preparation method thereof

A technology of mixed fermentation and pig manure, applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of increasing fermentation sites, increasing production personnel, reducing fertilizer nutrient content and fertilizer efficiency, and reducing fermentation sites and equipment , shorten the fermentation time and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

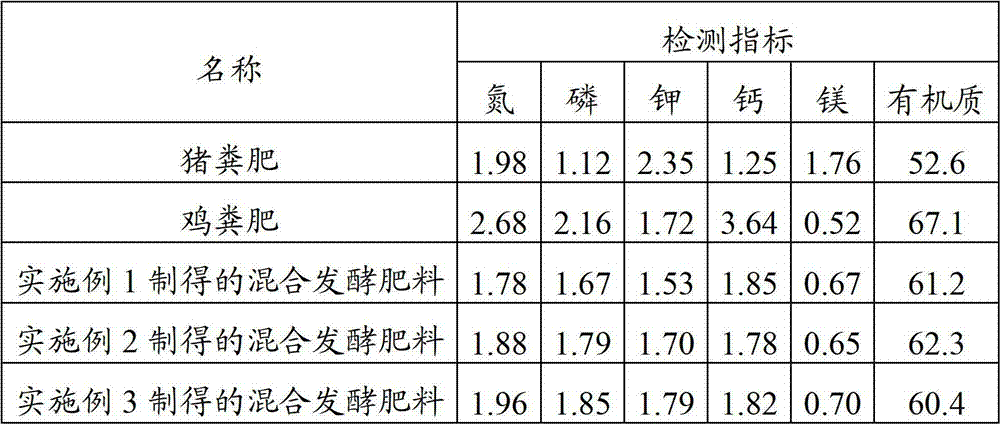

[0033] Embodiment 1: Preparation of chicken manure and pig manure mixed fermented fertilizer of the present invention

[0034] Take 1 kg of "Yijiayi" brand EM bacteria, 50 kg of straw powder, 1 kg of superphosphate, 10 kg of peat soil, 50 kg of chicken manure with a moisture content of 20% and 50 kg of pig manure with a moisture content of 20%. Evenly, adjust the moisture content to 50-65%, then pile it into the fermentation tank, keep the height of the material at 0.5-1.2 meters, control the temperature within 45°C to ferment for 2 days, and then control the temperature within 60-70°C to ferment for 3 days. The fermented material is dark brown, relatively fluffy, and has an earthy smell.

Embodiment 2

[0035] Embodiment 2: Preparation of chicken manure and pig manure mixed fermented fertilizer of the present invention

[0036] Take 50 kg of "Dongyi" brand EM bacteria, 200 kg of straw powder or rice bran, 20 kg of superphosphate, 200 kg of peat soil, 888 kg of chicken manure with a moisture content of 20% and 888 kg of pig manure with a moisture content of 20% Mix evenly, adjust the moisture content to 50-65%, then pile it into the fermentation tank, keep the height of the material at 0.5-1.2 meters, control the temperature within 45°C and ferment for 1 day; then control the temperature within 60-70°C and ferment for 5 days. , The fermented material is dark brown, relatively fluffy, and has an earthy smell.

Embodiment 3

[0037] Embodiment 3: Preparation of chicken manure and pig manure mixed fermented fertilizer

[0038] Take 25 kg of "Dongyi" brand EM bacteria, 100 kg of straw powder or rice bran, 10 kg of superphosphate, 100 kg of peat soil, 400 kg of chicken manure with a moisture content of 20% and 400 kg of pig manure with a moisture content of 20% Mix evenly, adjust the moisture content to 50-65%, then pile it into the fermentation tank, keep the height of the material at 0.5-1.2 meters, control the temperature within 45°C and ferment for 2 days; then control the temperature within 60-70°C and ferment for 4 days. , The fermented material is dark brown, relatively fluffy, and has an earthy smell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com