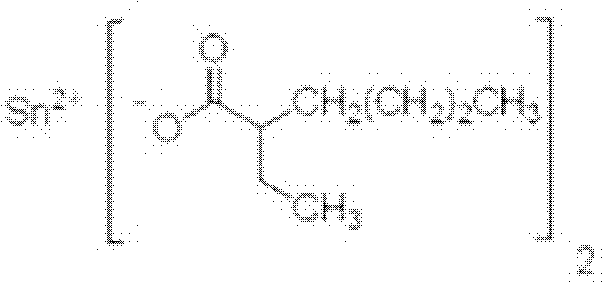

Preparation process of stannous octanoate

A technology of stannous octoate and preparation process, applied in the chemical industry, can solve the problems of unstable product quality, oxidation of stannous ions, troublesome operation, etc., and achieve the effects of stable quality, reduced reaction conditions and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

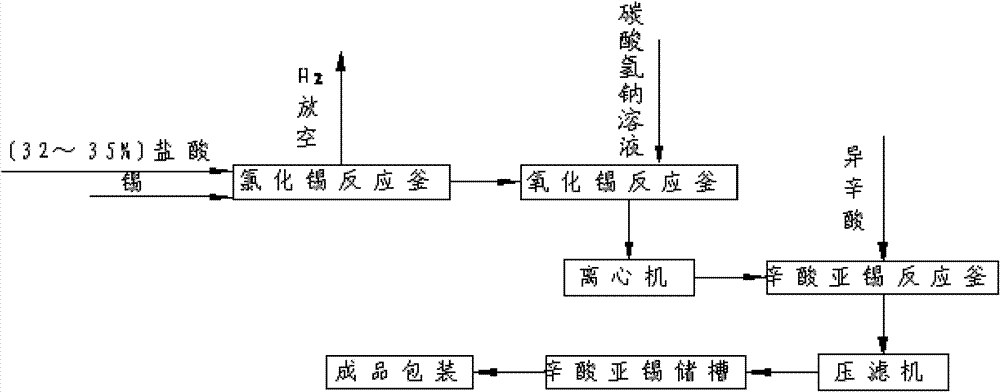

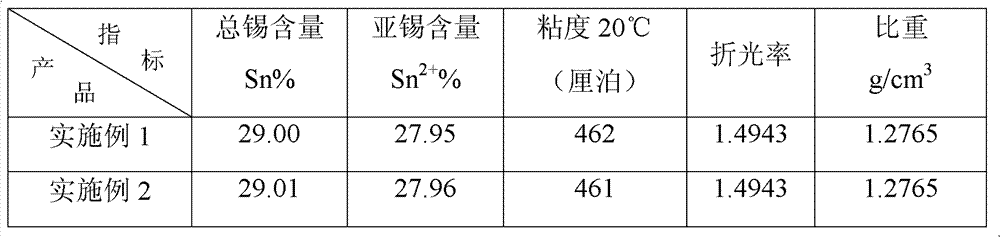

[0021] (1) SnCl Production: 119kg of tin is dropped into the reactor, then 208.6kg of hydrochloric acid solution with a concentration of 35% in mass percent is pumped into the reactor (HCl: Sn molar ratio 2: 1), the temperature rises To reflux state reaction 18 hours, H 2 Use a vent tube to put it high in the air, filter the reaction solution to remove unreacted tin, and filter the filtered SnCl 2 dilute solution (Sn 2+ mass content 10~12%) concentrated to Sn 2+ The mass percentage is 30%; the Sn contained in the solution 2+ It is 117.81kg, and the yield is 99%.

[0022] (2) 170.478kg of sodium bicarbonate is formulated into an aqueous solution of 10% by mass percentage and put into an open reactor, and the SnCl prepared in step (1) is added dropwise at 20°C. 2 solution (NaHCO 3 : SnCl 2 The molar ratio is 2.05:1), the pH value is controlled to 6-6.2 to the end of the reaction, and the reaction solution after the reaction is centrifugally filtered to obtain stannous oxid...

Embodiment 2

[0025] (1) SnCl Production: 119kg of tin is dropped into the reactor, and then 260.71kg is squeezed into the reactor by pumping 260.71kg of 35% hydrochloric acid solution in terms of mass percentage concentration (HCl: Sn molar ratio 2.5: 1), Be warming up to reflux state reaction 19 hours, H 2 Use a vent tube to put it high in the air, filter the reaction solution to remove unreacted tin, and filter the filtered SnCl 2 dilute solution (Sn 2+ mass content 10~12%) concentrated to Sn 2+ The mass percentage is 30%; the Sn contained in the solution 2+ Be 117.929kg, product yield is 99.2%;

[0026] (2) 167.489kg of sodium bicarbonate is formulated into an aqueous solution of 10% by mass percentage and put into an open reactor, and the SnCl prepared in step (1) is added dropwise at 20°C. 2 solution (NaHCO 3 : SnCl 2 The molar ratio is 2.01:1), and the pH value is controlled to 6-6.2 to the end of the reaction, and then the reaction solution after the reaction is centrifugally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com