Black bisazo thioether sulfoacid compound or black bisazo thioether sulfoacid compound salts, and preparation method and application thereof

A technology of bisazo sulfide and sulfonic acid compounds, which is applied in the preparation of sulfides, the preparation of azo dyes, chemical instruments and methods, etc. The effect of ozone fastness and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The ink composition of the present invention is prepared by dissolving the black bis-azosulfide sulfonic acid compound or its salt, or its mixture, in water or the water-soluble organic solvent as required, and It is prepared by dissolving it together with the above-mentioned ink additives and the like.

[0060] In the above production method, there is no particular limitation on the order in which the components are dissolved. The dye may be dissolved in water or the water-soluble organic solvent in advance, and the ink control agent may be added to dissolve the dye, or an aqueous solvent or an ink preparation agent may be added after dissolving the dye in water. The order may be different from this. Furthermore, an ink composition may be produced by adding a water-soluble organic solvent and an ink additive to a solution obtained by desalting a reaction liquid containing the dye or a solution containing the pigment by reverse osmosis membrane. When preparing the ink...

Embodiment 1

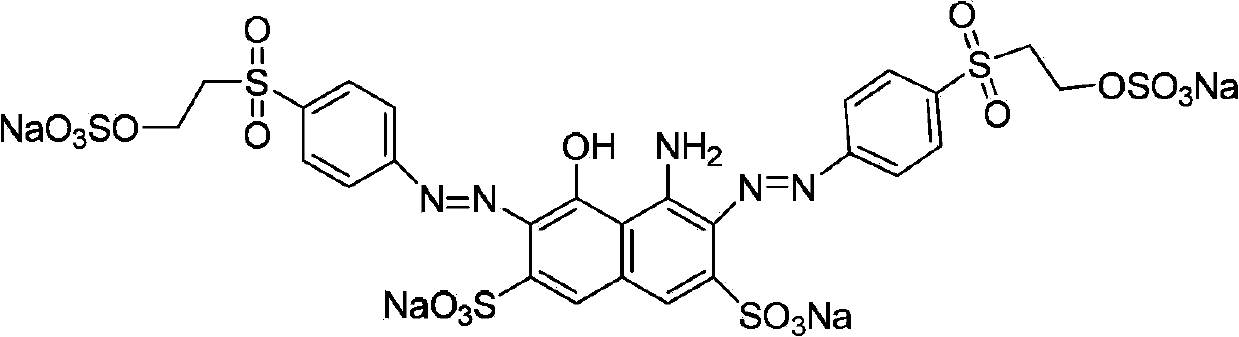

[0070] 36.5 parts of 2-amino-5-(2-sulfonic acid oxyethylsulfone) benzenesulfonic acid (commonly known as sulfonated para-ester), dissolved in 200 grams of water under stirring, added 37.5 parts of 30% hydrochloric acid, added 50 parts of ice , cooled to -10--5°C, added dropwise 50 parts of aqueous solution containing 7 parts of sodium nitrite under stirring, maintained the reaction temperature at about -5°C, stirred for 1 hour, added 3 parts of urea, and filtered after stirring for 0.5 hours to obtain Clear diazotization solution.

[0071] Dissolve 18 parts of 4-amino-5-hydroxy-naphthalene-2,7-disulfonic acid (commonly known as H-acid) in 100 parts of water, adjust the pH to 3-4 with 20% aqueous sodium hydroxide solution, add 50 parts of ice cubes , Under stirring, drop about 60% diazotization solution, keep the temperature below 5°C, and stir for 2-3 hours to obtain a red solution. Then adjust the pH to 9-10 with 20% sodium hydroxide aqueous solution, add the remaining diazo...

Embodiment 2

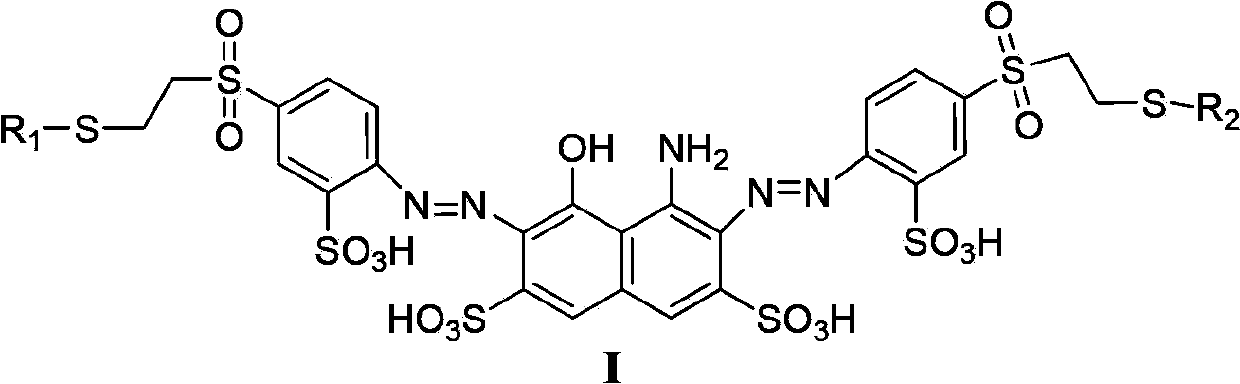

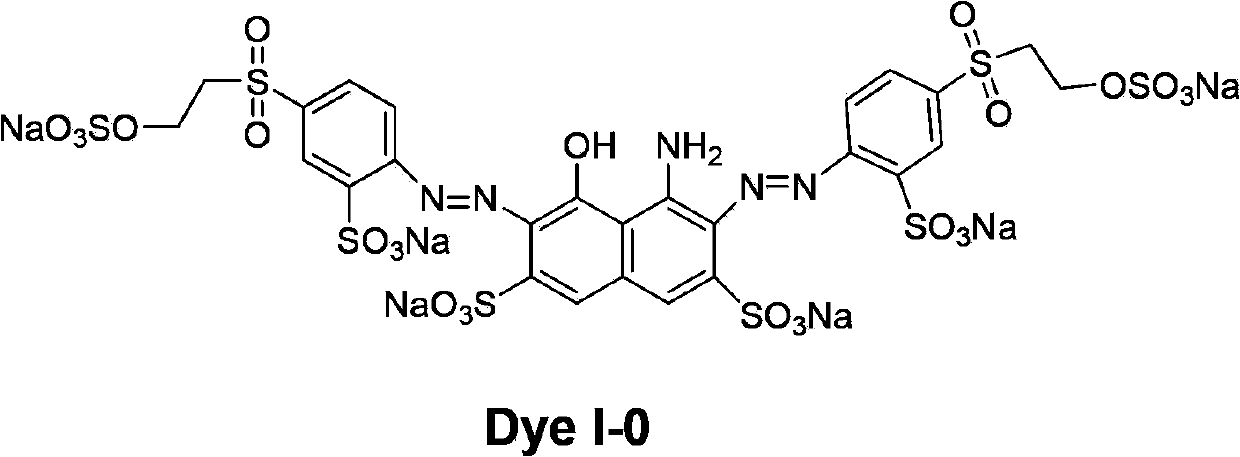

[0076] Weigh 11.6 parts of the dye Dye I-0 obtained in Example 1, dissolve it in 100 parts of water, add 2 parts of mercaptoethanol, adjust the pH at 9.5-10.5 with 20% sodium hydroxide, stir and heat up to 50-60°C, and react During this period, sodium hydroxide was continuously added dropwise to maintain the pH until the pH was constant. The reaction solution was cooled. Use high-pressure reverse osmosis membrane system to remove the inorganic salt in the system, after concentrating, add the methanol of same volume, black precipitate separates out, filters, and dries, obtains 10 parts of black dye Dye-1, and its mass spectrum (EI-MS) m / z ( -) is: 254.8([ M -4Na] 4- / 4);347.3([ M -3Na] 3- / 3),353.3([ M -4Na+H] 3- / 3); 532.5([ M -2Na] 2- / 2),521.5([ M -3Na+H] 2- / 2),510.5([ M -4Na+2H] 2- / 2). The most abundant and accurate molecular mass of dye Dye-1 M for 1110.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com