Preparation and application of composite material coupling agent

A composite material and coupling agent technology, which is applied in the field of preparation of composite material coupling agent, can solve problems such as high cost and complicated treatment process, and achieve the effects of increased recovery rate, shortened reaction time, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

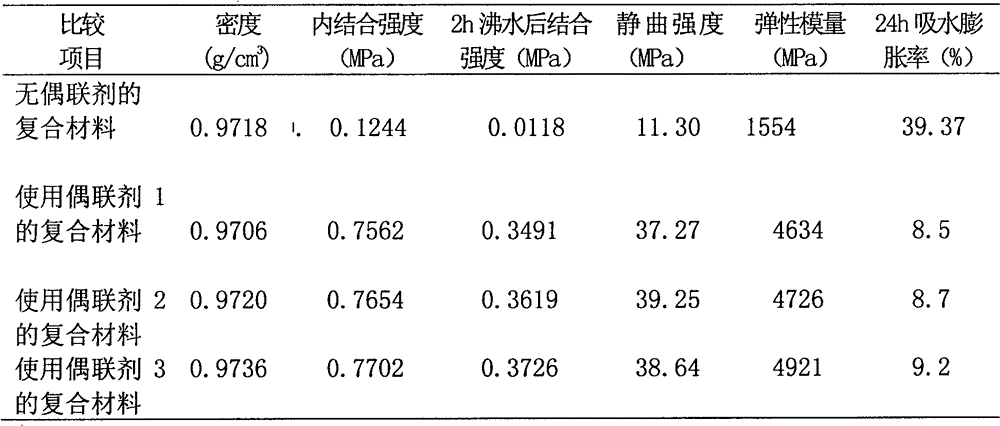

Examples

Embodiment 1

[0043] The preparation of a composite material coupling agent.

[0044] (1) Refinement of crude glycerin

[0045] To 100g of crude glycerin, add 10g of methanol, neutralize with hydrochloric acid, and centrifuge, the lower layer is used to prepare soap, the upper layer is distilled under reduced pressure, the methanol obtained is recycled, the temperature is raised to 105-110 ° C, and the vacuum is distilled for 1h , to obtain refined glycerin;

[0046] The crude glycerol is a by-product crude glycerol phase separated in the biodiesel alcoholysis process; the biodiesel alcoholysis uses raw material of food waste oil;

[0047] (2) Preparation of hydroxyl-terminated polyol aqueous emulsion

[0048] In a dry and clean flask, add 100 g of refined glycerin, add 50 g of polyether polyol, 10 g of succinic anhydride, and 0.05 g of butyl titanate under stirring, and heat with a microwave with a power of 400 W for 10 min; add ethylenediamine ethanesulfonate Acid 2g, succinic anhydrid...

Embodiment 2

[0052] The preparation of a composite material coupling agent.

[0053] (1) Refinement of crude glycerin

[0054] To 100g of crude glycerol, add 15g of acetone, then neutralize with sulfuric acid and centrifuge, the lower layer is used to prepare soap, the upper layer is distilled under reduced pressure, the obtained acetone is recycled, the temperature is raised to 105-110 ° C, and the vacuum is distilled for 1h , to obtain refined glycerin.

[0055] The crude glycerin is the same as in Example 1.

[0056] (2) Preparation of hydroxyl-terminated polyol aqueous emulsion

[0057] In a dry and clean flask, add 100 g of refined glycerin, add 100 g of polyether polyol, 20 g of succinic anhydride, and 0.10 g of isopropyl titanate under stirring, and heat with a microwave with a power of 400 W for 15 minutes; add ethylene diamine ethyl 10g of sulfonic acid and 10g of succinic anhydride, continue to heat for 15min with a microwave with a power of 400W, and then continue to heat for...

Embodiment 3

[0062] The preparation of a composite material coupling agent.

[0063] (1) Refinement of crude glycerin

[0064] In the crude glycerol of 100g, add the methyl acetate of 13g, neutralize with hydrochloric acid, centrifuge again, the lower layer is used for preparing soap, and the upper layer is distilled under reduced pressure, and the methyl acetate obtained is recycled, and the temperature rises to 105-110 ℃ , distilled under reduced pressure for 1h to obtain refined glycerol.

[0065] The crude glycerin is the same as in Example 1.

[0066] (2) Preparation of hydroxyl-terminated polyol aqueous emulsion

[0067] In a dry and clean flask, add 100 g of refined glycerin, add 75 g of polyether polyol, 15 g of succinic anhydride, and 0.075 g of isobutyl titanate under stirring, and heat with a microwave with a power of 400 W for 12 minutes; add ethylene diamine ethyl 7g of sulfonic acid and 15g of succinic anhydride, continue to heat for 13min with a microwave with a power of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com