Microbial compound bacteria agent for treating oilfield fracturing flowback fluid, and preparation method of microbial compound agent

A technology of microorganisms and liquid bacteria, applied in the biological field, can solve the problems of secondary pollution and difficult degradation of fracturing flowback fluid, and achieve the effect of clear water quality, high degradation rate and reduction of secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Separation and purification of Cladosporium mold and Pyrobacterium bovis

[0023] Taking the oilfield fracturing fluid flowback fluid as the sampling source, the fracturing fluid flowback fluid was diluted to 10 -1 ~10 -10 Dilute it, spread it on a solid medium containing 3% high-molecular organic compound guar gum, and cultivate it at a temperature of 30°C for 5 days.

[0024] A single colony was picked on the above plate and separated and purified by streaking on the plate to obtain two strains EB1 and EB2 with excellent traits.

Embodiment 2

[0025] Example 2 Sequencing and identification of strain EB1

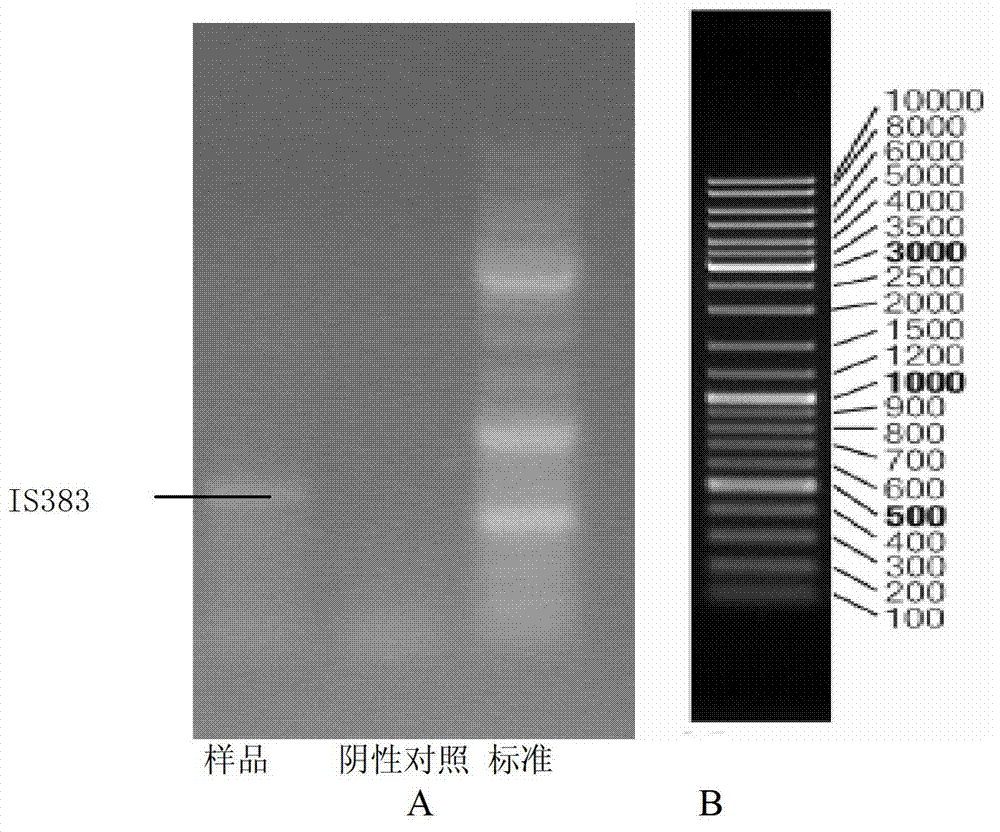

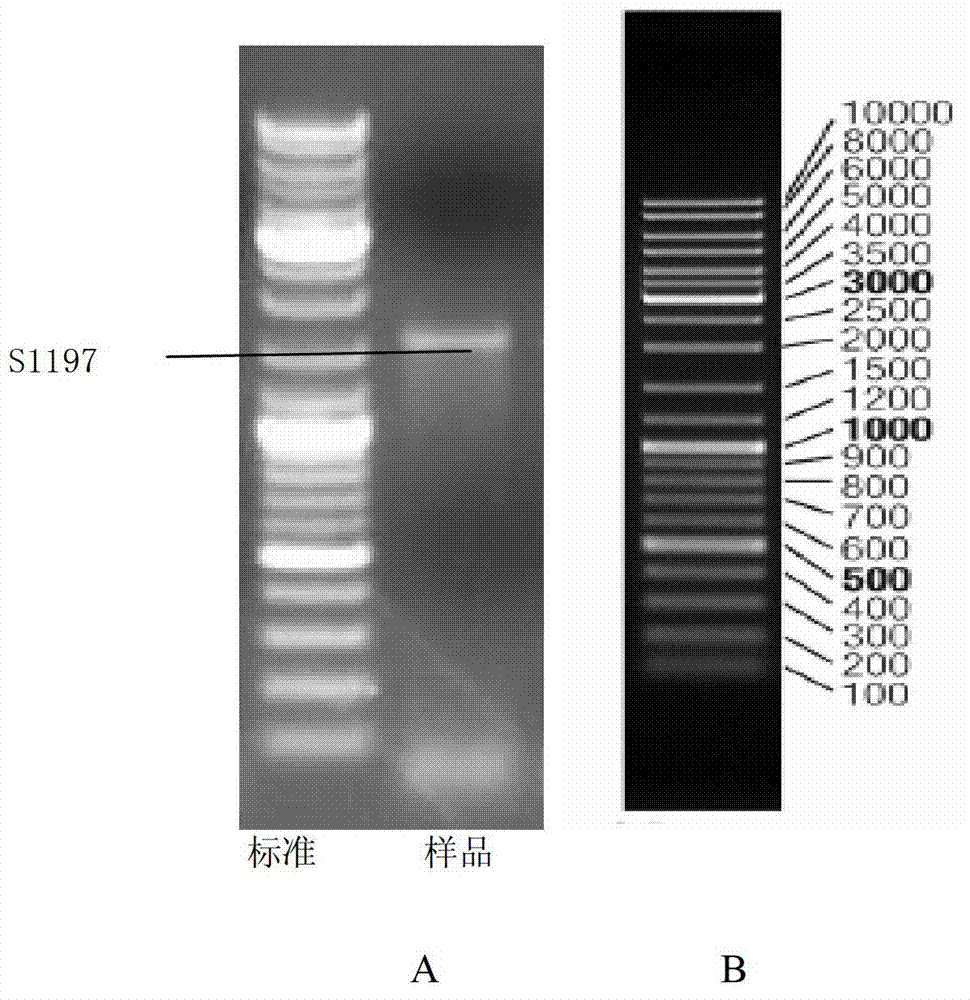

[0026] 1. Genome extraction and electrophoresis detection

[0027] (1) Genome extraction process: Extract according to the method described in the instruction manual of the SK1375 Fungal Genome DNA Extraction Kit of Shanghai Sangon Bioengineering Technology Service Co., Ltd.

[0028] The extraction steps are described as follows:

[0029] 1. Take 50-100mg of fresh fungus or 20mg of dried fruiting bodies or mycelia, and grind them into powder in liquid nitrogen. Add 700 μl 65°C preheated FPCB Solution and 7 μl β-mercaptoethanol in sequence, mix thoroughly, and incubate at 65°C for 25 minutes, mixing occasionally.

[0030] 2. Centrifuge at 12,000rpm for 10min, transfer the supernatant to a clean 1.5ml centrifuge tube, add 700μl chloroform, mix well, and centrifuge at 12,000rpm for 5min.

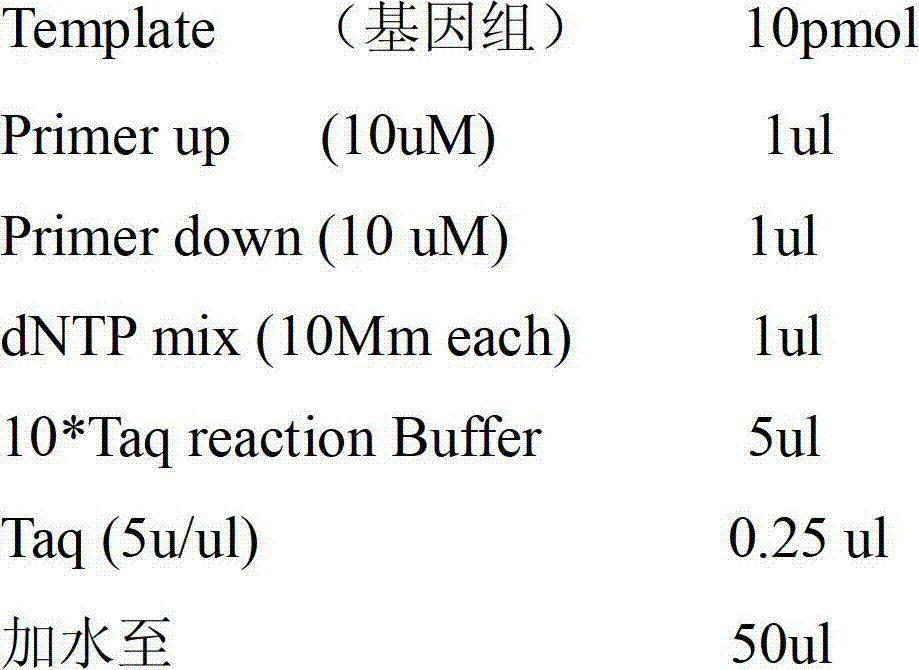

[0031] 3. Pipette the supernatant into a clean 1.5ml centrifuge tube, add 40μl RNase A (20mg / ml), mix well, and place at room t...

Embodiment 4

[0112] Example 4 A preparation method of a microbial composite bacterial agent for treating oil field fracturing flowback fluid

[0113] The strains with the preservation number CGMCC No: 5782 and the preservation number CGMCC No: 5783 were put into two mediums for shaker culture respectively. The medium was composed of water, and each liter of water contained 0.1g-5g of guanidine Glue, 0.05g~1g of KH 2 PO 4 , 0.05g ~ 2g of K 2 HPO 4 , 0.01g~0.1g of MgSO 4 , 0.01g ~ 0.5g of CaCl 2 , 0.01g ~ 0.2g of NaCl, the cultivation time is 3 ~ 10 days, the cultivation temperature is 5 ~ 30 ° C, and then the inoculum amount is 5% ~ 15% by volume in the two reactors equipped with the above medium Inoculate the above two strains respectively, culture continuously for 8-48 hours to obtain a liquid bacterial liquid, and then mix the liquid bacterial liquid containing Cladosporium and the liquid bacterial liquid containing Bacillus bovis according to the ratio of 1 to 5:1 by volume Compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com