Spectrum device for measuring LED (light-emitting diode) epitaxial wafer photoluminescence on line

A light-emitting diode, photoluminescence technology, applied in the direction of emission spectrum, spectrum investigation, etc., to achieve the effect of ensuring normal growth, reducing economic losses, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

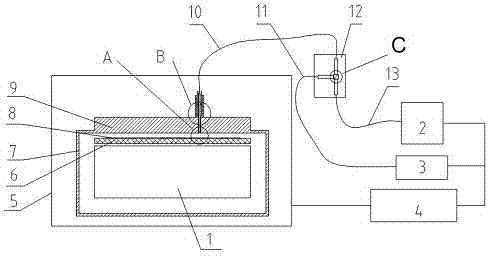

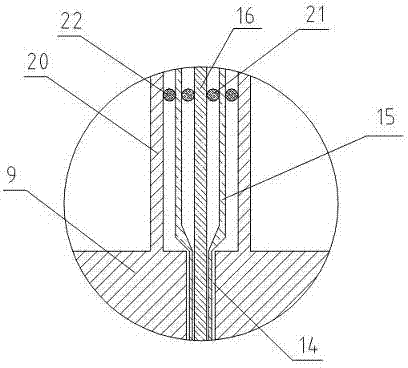

[0020] An on-line device for measuring the photoluminescence spectrum of a light-emitting diode epitaxial wafer includes a reaction chamber 7 and a control system 4 , and an MOCVD heater 1 is installed in the reaction chamber 7 placed in a glove box 5 . A graphite base 6 and an epitaxial wafer 8 are installed sequentially from bottom to top on the MOCVD heater 1 , the MOCVD heater 1 heats and controls the temperature of the graphite base 6 , and the graphite base 6 heats the epitaxial wafer 8 . On the top of the reaction chamber 7, an MOCVD shower head 9 facing the epitaxial wafer 8 and spaced from the epitaxial wafer 8 is installed. A quartz rod assembly hole 14 perpendicular to the epitaxial wafer 8 and penetrating is processed on the MOCVD shower head 9. The quartz rod assembly It consists of a quartz rod 16 and a quartz rod jacket 15 that is covered on the outer wall of the quartz rod 16. An outer sealing metal tube 20 is provided on the top of the outer wall of the MOCVD n...

Embodiment 2

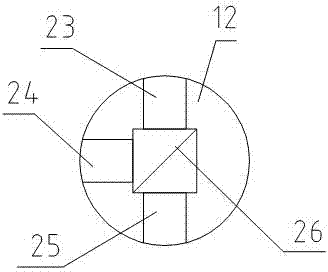

[0029] The structure of embodiment 2 is basically the same as embodiment 1, the difference is:

[0030] exist Figure 5 In, use Y-shaped fiber block 28 to replace the whole Figure 4 The fiber branch block 12 in the part, the Y-shaped fiber block 28 is made up of dry fiber 27, spectrum fiber 11 and laser fiber 13, and dry fiber 27 is exactly to form by combining spectrum fiber 11, laser fiber 13 in fact, and then jointly with quartz rod The end face of 16 realizes the coupling, and even cancels the quartz rod 16, and directly extends the two optical fibers into the reaction chamber 7, and at this time, vacuum seals between the optical fibers and the reaction chamber. The coupling efficiency of using the Y-shaped fiber block 28 will be reduced by at least a factor of 1, although it is convenient.

[0031]In order to prevent the laser light reflected by the epitaxial wafer 8 (containing the film thickness information of the epitaxial wafer) from entering the fiber optic spectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com