Preparation method of lauryl glucopyranoside

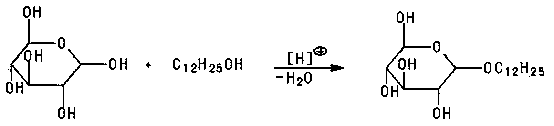

A technology of glucoside and lauryl, which is applied in the field of preparation of non-ionic surfactants, can solve the problems of long condensation reaction time, long reaction time, and slow reaction speed, so as to improve the reaction rate and yield and reduce sugar Effects of occurrence of side reactions, improvement of conversion rate and rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

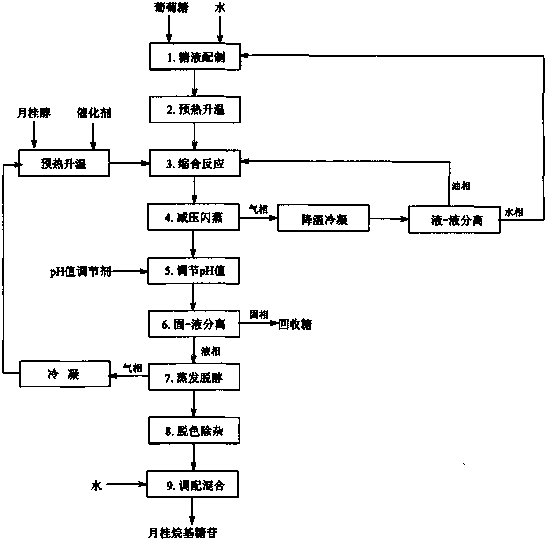

[0046] The main process equipment is: stirring equipment, condensation reactor, decompression flash reaction equipment, neutralization reactor, dealcoholization reactor, decolorization and impurity removal equipment, solid-liquid separation equipment, deployment and mixing equipment, etc., among which the condensation reactor is jet The flow chemical reactor, the decompression flashing equipment is a flash tank, the neutralization reactor is a tank-type stirred chemical reactor, the evaporative dealcoholization equipment is an evaporator, the decolorization and impurity removal equipment is a flat-plate electrochemical reactor, and the stirring equipment is The tank reactor, the deployment and mixing equipment is the deployment and mixing tank.

[0047] As shown in the figure, a method for preparing lauryl alkyl glucoside is a method for preparing lauryl alkyl glucoside aqueous solution with lauryl alcohol and glucose as raw materials, and the method steps are as follows:

[0...

Embodiment 2

[0058] Main process equipment is: basically the same as embodiment one, the difference is that the condensation reactor is an impingement flow chemical reactor, and the decolorization and impurity removal equipment is a fixed bed electrochemical reactor.

[0059] As shown in the figure, a method for preparing lauryl alkyl glucoside is a method for preparing lauryl alkyl glucoside aqueous solution with lauryl alcohol and glucose as raw materials, and the method steps are as follows:

[0060] (1) Preparation of sugar solution: 10 kg of water was added to the tank reactor, and then 10 kg of glucose was added thereto, and the mass ratio of glucose to water was 1.0: 1.0;

[0061] (2) Preheating and heating: heat the sugar liquid material obtained in the previous step to 90°C, and then keep it warm;

[0062] (3) Condensation reaction: The sugar solution preheated in the previous step and the alkyd mixture material that has been preheated to 170°C are respectively filtered to remove ...

Embodiment 3

[0070] The main process equipment is: basically the same as in Example 1, the difference is that the condensation reactor is a plug-flow chemical reactor, and the decolorization and impurity removal equipment is a fluidized bed electrochemical reactor.

[0071] As shown in the figure, a method for preparing lauryl alkyl glucoside is a method for preparing lauryl alkyl glucoside aqueous solution with lauryl alcohol and glucose as raw materials, and the method steps are as follows:

[0072] (1) Preparation of sugar solution: 10 kg of water was added to the tank reactor, and then 9 kg of glucose was added thereto, and the mass ratio of glucose to water was 0.9: 1.0;

[0073] (2) Preheating and heating: heat the sugar liquid material obtained in the previous step to 100°C, and then keep it warm;

[0074] (3) Condensation reaction: The sugar solution preheated in the previous step and the alkyd mixture material that has been preheated to 185°C are respectively filtered to remove so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com