Composite modified aqueous polyurethane resin and its preparation method

A water-based polyurethane and composite modification technology, applied in the direction of coating, can solve the problems of poor water resistance, solvent resistance and weather resistance, and insufficient cross-linking density of the paint film, and achieve the effects of good water resistance, low cost and high gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

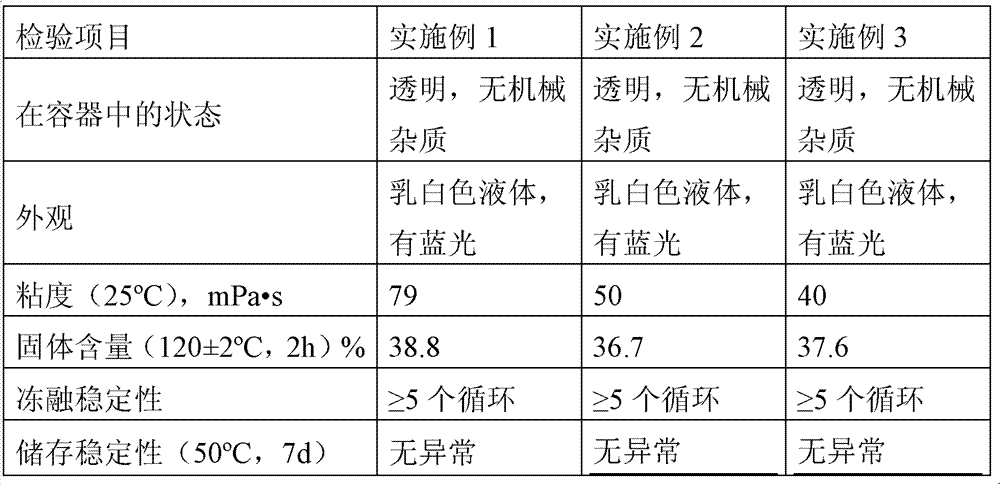

Examples

Embodiment 1

[0053] A kind of preparation method of the aqueous polyurethane resin of composite modification, comprises the following steps:

[0054] (1) Add 102.5g of polyether glycol, 23g of castor oil, and 90.5g of isophorone diisocyanate in a 1000mL four-neck flask equipped with a stirring device, a thermometer and a nitrogen protection, and start stirring and heating at the same time, Insulate at 80-90°C for 2 hours;

[0055] (2) Add 11.6g 1,4-butanediol, 10g epoxy resin E20 (product of Suzhou Sutong Resin Co., Ltd.), 0.1g dibutyltin dilaurate, 15.6g dimethylol propionic acid, 80g N-formazan Base pyrrolidone, at 80-84 ℃, keep warm for 30 minutes;

[0056](3) Start to measure NCO. When the NCO value reaches 1.97%, cool down to below 40°C and add vinyl monomers (50g methyl methacrylate, 10g butyl acrylate, 8g N-methylol acrylamide);

[0057] (4) Add 10.1 g of triethylamine, stir at 2100 rpm for 30 minutes, add 450 g of deionized water and 4.0 g of ethylenediamine while stirring at 250...

Embodiment 2

[0060] A kind of preparation method of the aqueous polyurethane resin of composite modification, comprises the following steps:

[0061] (1) Add 90g of polyester diol, 35g of castor oil, and 63g of toluene diisocyanate into a 1000mL four-neck flask equipped with a stirring device, a thermometer and nitrogen protection in sequence, and start stirring and heating at the same time, at 80-90°C keep warm for 2 hours;

[0062] (2) Add 10.4g diethylene glycol, 10g epoxy resin E44 (Suzhou Sutong Resin Co., Ltd. product), 0.1g stannous octoate, 13.6g dimethylol propionic acid, 80g N-methylpyrrolidone, At 80-84°C, keep warm for 30 minutes;

[0063] (3) Start to measure NCO, when the NCO value reaches 1.88%, cool down to below 40°C, add vinyl monomers (52g methyl methacrylate, 8g butyl acrylate, 2g 2-hydroxyethyl methacrylate , 8g N-methylolacrylamide);

[0064] (4) Add 10.3g triethylenediamine, 2 Stir at 100 rpm for 30 minutes, then add 450 g of deionized water and 4.5 g of isophoro...

Embodiment 3

[0067] A kind of preparation method of the aqueous polyurethane resin of composite modification, comprises the following steps:

[0068] (1) Add 112.5g polyether glycol, 33g castor oil, 90.5g 4,4'-diphenylmethane diisocyanate in a 1000mL four-necked flask equipped with stirring device, thermometer and nitrogen protection successively, simultaneously Start stirring and heating, and keep warm at 80-90°C for 2 hours;

[0069] (2) Add 12.6g 1,6-hexanediol, 10g epoxy resin E51 (product of Suzhou Sutong Resin Co., Ltd.), 0.1g N-methylmorpholine, 14.8g dimethylolbutyric acid, 80g N- Ethylpyrrolidone, at 80-84°C, keep warm for 30 minutes;

[0070] (3) Start to measure NCO, when the NCO value reaches 1.16%, cool down to below 40°C, add vinyl monomers (51g methyl methacrylate, 9g butyl acrylate, 2g isobornyl methacrylate, 8g N -methylolacrylamide), cooling to below 40°C;

[0071] (4) Add 11.2g of N,N-dimethylethanolamine, stir at 2100rpm for 30 minutes, add 515g of deionized water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com