Reflection type color filter

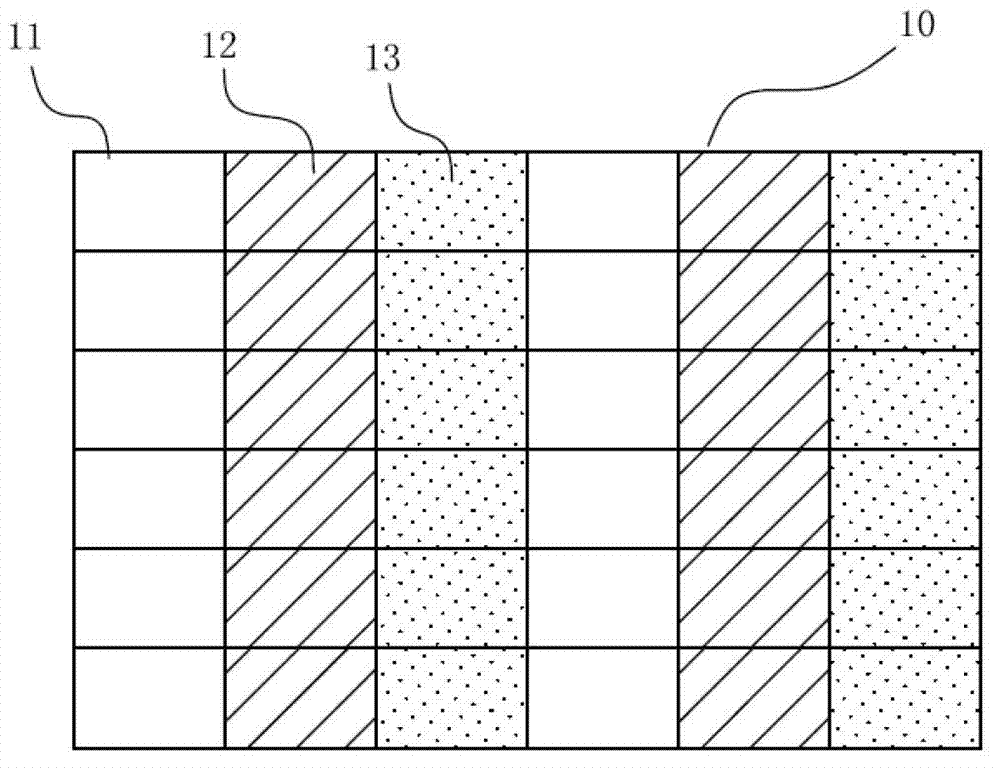

A color filter, reflective technology, applied in optics, optical components, instruments, etc., can solve the problems of unfavorable energy saving and environmental protection, low utilization rate of light energy, etc., to improve the utilization rate of light energy and reduce the sensitivity of angle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

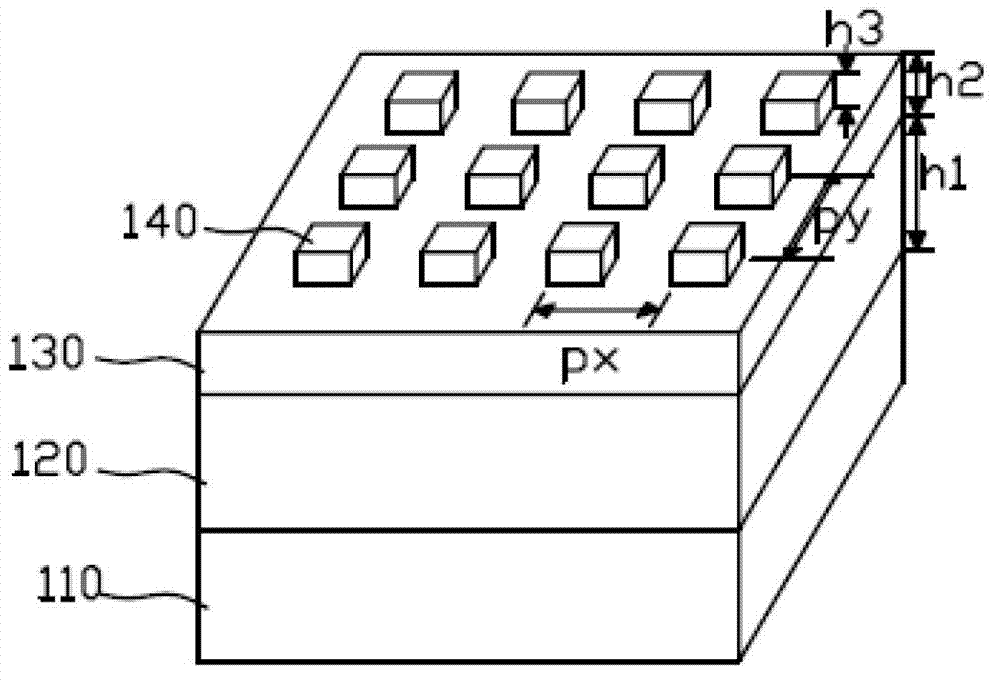

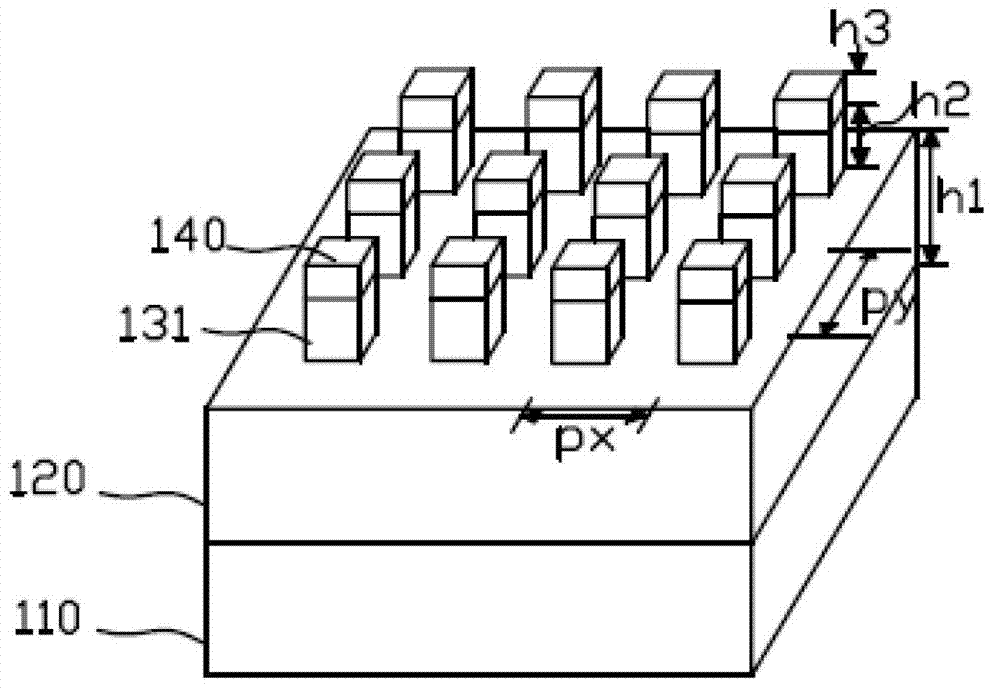

[0047] In this embodiment, the formation of a magenta grating structure is taken as an example for illustration.

[0048] Please continue to see figure 2 , in this embodiment, the substrate 110 is a flexible material, specifically PET or PC. Metal layer 120 is aluminum. The material of the dielectric layer 130 is PMMA. The material of the metal grating layer 140 is aluminum. Further, the periods of the dot-matrix metal grating 120 in the X direction and the Y direction are both px=py=p, and the duty ratio is F. The following structural parameters are obtained for the magenta reflective filter design: period p=190nm, duty ratio F=0.45. The thickness of the metal layer h1 = 150 nm. The dielectric layer thickness h2=15nm. The thickness h3 of the metal grating layer is 25 nm.

[0049] TM polarized light and TE polarized light are incident from the top of this structure. The incident angle of light varies from 0° to 45°. The reflection characteristics and angle tolerance ...

Embodiment 2

[0054] In this embodiment, different color filter structures corresponding to different duty ratios are studied. In this embodiment, the duty ratio of the pixel structure takes three values of 0.33, 0.44, and 0.55 respectively, while other parameters remain unchanged. The thickness of the layer h1 = 150 nm. The dielectric layer thickness h2=15nm. The thickness h3 of the metal grating layer is 25 nm.

[0055] See Figure 6 , Figure 6 It is the relationship diagram of reflection efficiency of TM light with incident wavelength and duty ratio. When F changes between 0.33 and 0.55, the position of the reflection valley changes. For example, when F=0.33, the blue light close to 450nm is absorbed, and the light in other bands is reflected, so that the color of the light reflected by the pixel structure under this duty ratio is yellow; when F=0.44, close to The green light at 550nm is absorbed, while the light in other bands is reflected, so that the color of light reflected ...

Embodiment 3

[0057] In this embodiment, different color filter structures corresponding to different metal grating periods are studied. In this embodiment, the periods of the metal gratings in the pixel structure are 0.15um, 0.19um, and 0.23um respectively, and other parameters are consistent with those in the first embodiment. That is, the duty ratio F=0.45, and the thickness h1 of the metal layer=150nm. The dielectric layer thickness h2=15nm. The thickness h3 of the metal grating layer is 25 nm.

[0058] See Figure 7 , Figure 7 It is the relationship diagram of the reflection efficiency of TM light with the incident wavelength and period. When p changes between 0.15 and 0.23um, the position of the reflection valley changes. For example, when p=0.15um, the blue light close to 450nm is absorbed, while the light in other bands is reflected, so that the color of the light reflected by the pixel structure under this duty ratio is yellow; when p=0.19um , the green light close to 550nm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grating period | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com