Production method of gallium nitride (GaN)-based light emitting diode (LED) chip with indium tin oxide (ITO) surface roughness

A technology of LED chip and surface roughening, which is used in electrical components, circuits, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

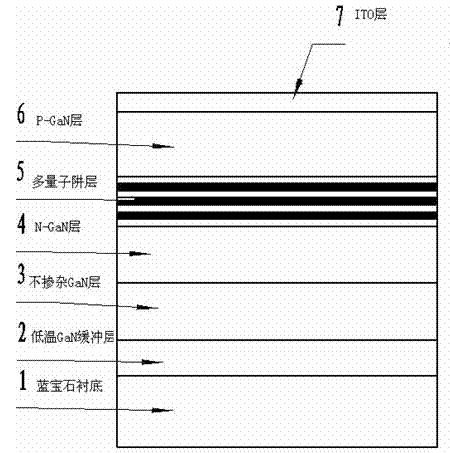

[0034] 1. Making LED chips:

[0035] Step 1: Using metal-organic chemical vapor deposition (MOCVD), sequentially grow 1 μm low-temperature GaN buffer layer 2, 2 μm undoped GaN layer 3, 2 μm N-GaN layer 4, and 250 nm multi-quantum well light emission on the semiconductor substrate 1 Layer 5 and 300nm P-GaN layer 6 to form a GaN epitaxial wafer.

[0036] The aforementioned semiconductor substrate 1 can be any one of sapphire, silicon, silicon carbide or metal.

[0037] Step 2: Prepare an ITO thin film layer on the upper surface of the P-GaN layer 6 of the GaN epitaxial wafer, with a thickness of 500-9000 Å, such as figure 1 shown.

[0038] Step 3: Process the surface of the ITO thin film layer 7 to make a nano-bowl-shaped roughened surface, the following steps:

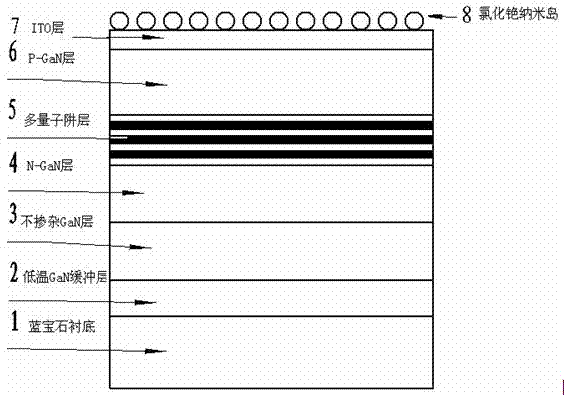

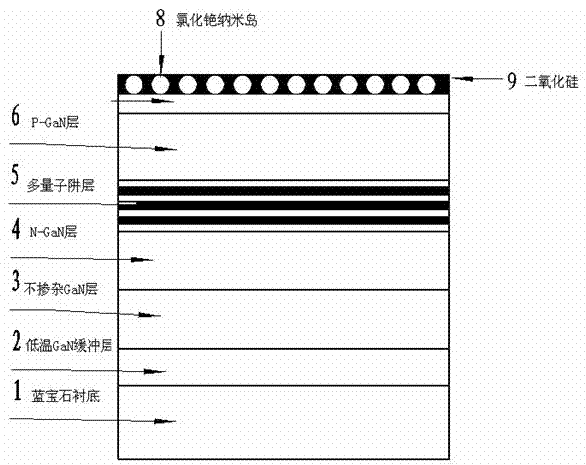

[0039] (1) Put the GaN epitaxial wafer covered with the ITO thin film layer 7 into the evaporation table, and evaporate a cesium chloride thin film on the surface of the ITO thin film layer 7 for 5 to 40 minutes. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Etching power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com