Rear-contact heterojunction photovoltaic cell

A photovoltaic cell and back surface technology, applied in photovoltaic power generation, circuits, electrical components, etc., to achieve the effects of simplified manufacturing process, good passivation, and small ohmic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In the following description, the invention will be described in more detail without limitation with reference to photovoltaic applications of the invention.

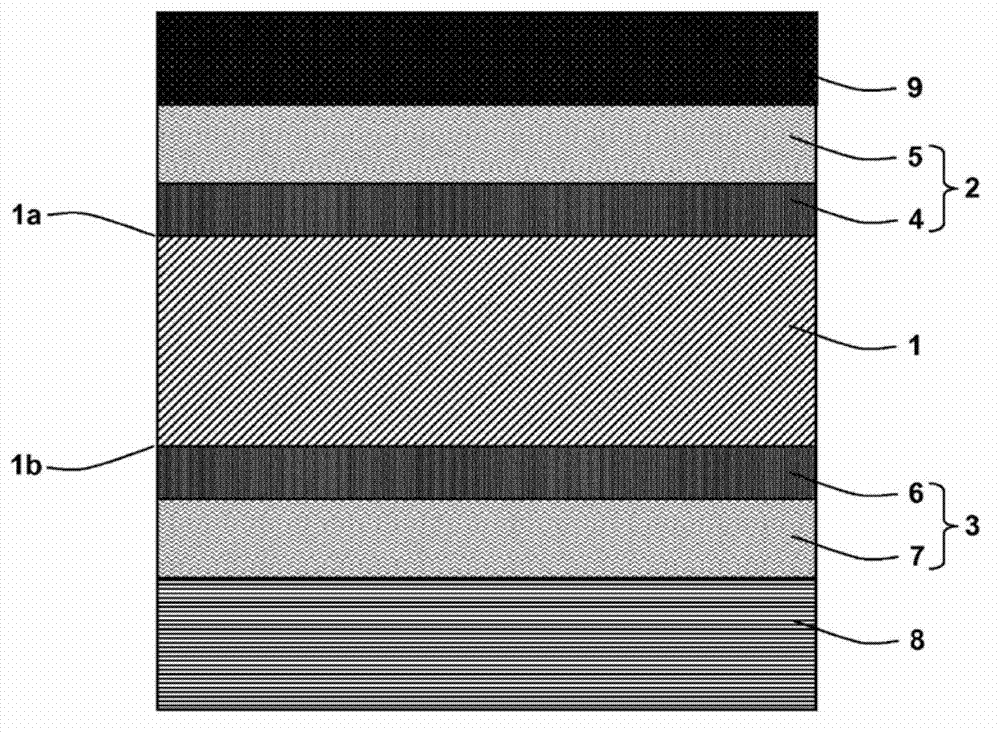

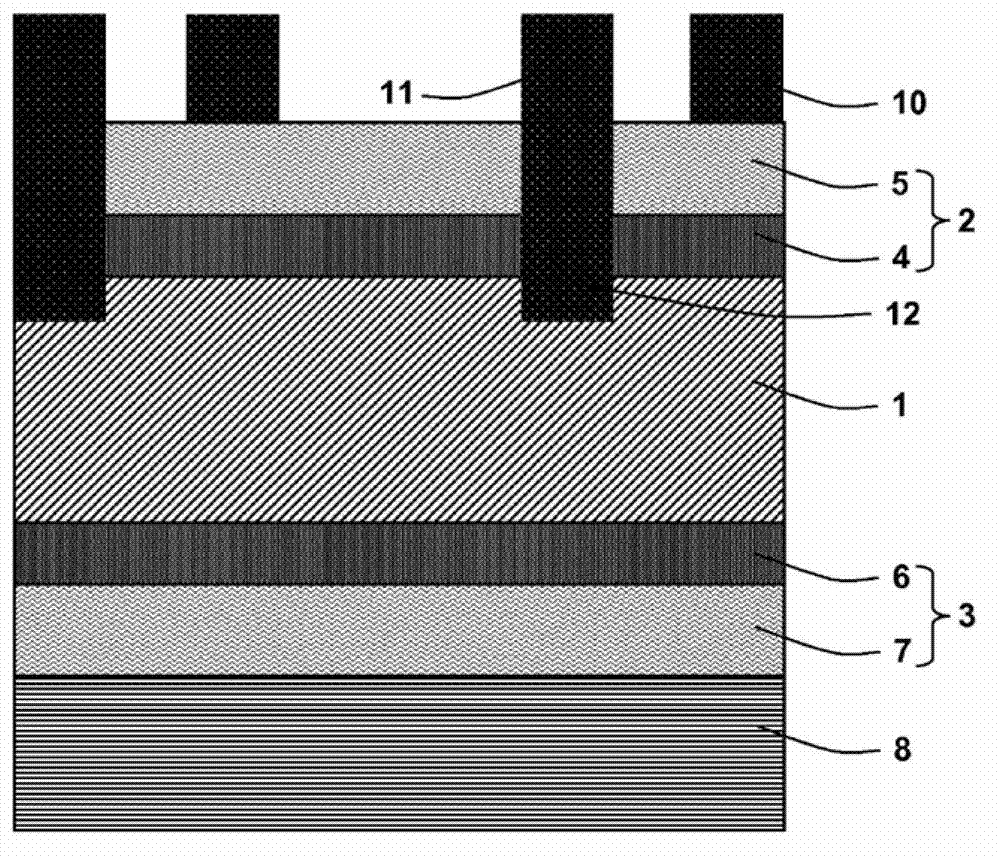

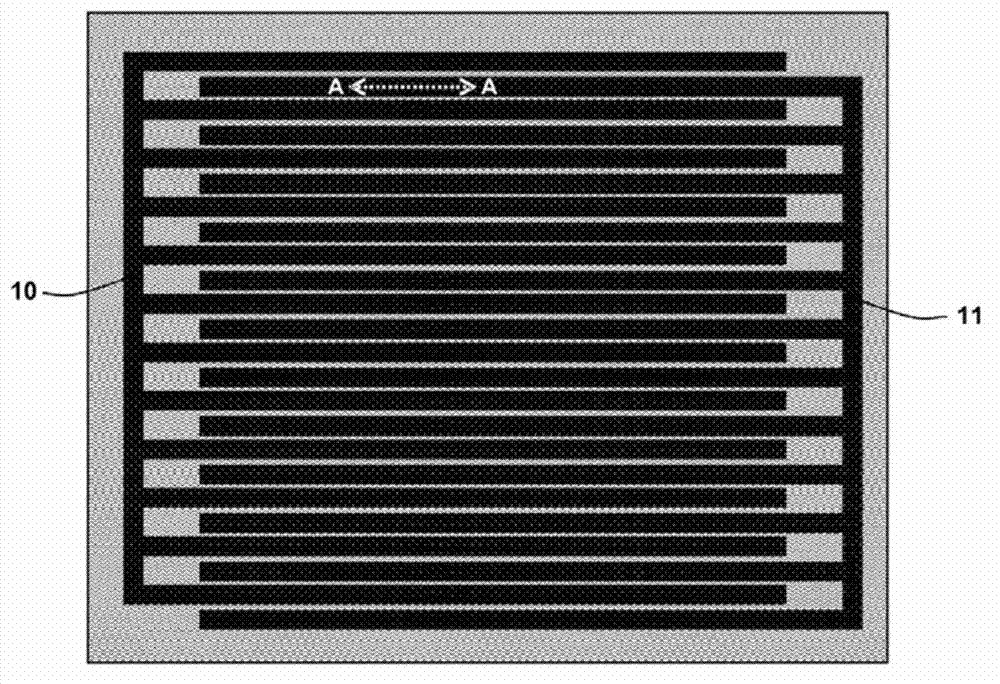

[0062] see figure 1 , the semiconductor device according to the present invention can be fabricated as follows.

[0063] First, a crystalline semiconductor substrate 1 having a front surface 1a and a back surface 1b is provided. Preferably, the crystalline semiconductor substrate 1 is a crystal, especially a monocrystalline or polycrystalline (preferably monocrystalline) silicon substrate (or wafer) in the form of a wafer.

[0064] The substrate can be doped n-type or p-type. The use of n-type doped substrates is particularly advantageous due to their longer lifetime. In the following, an n-type doped substrate is taken as an example. Advantageously, the substrate 1 does not have any oxide material.

[0065] Preferably, the substrate 1 has sufficient doping to have a resistivity between about 0.1 and 1 Ω·cm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com