Low-energy-consumption preparation method of pitch-based spherical active carbon

A spherical activated carbon and pitch-based technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of energy consumption and long time, and achieve saving production time, fast curing speed and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

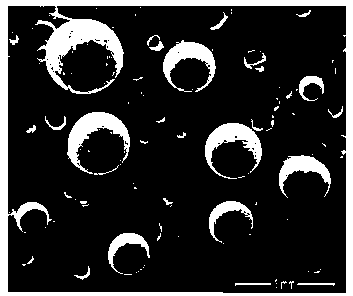

Image

Examples

Embodiment 1

[0013] (1) After mixing 100g of benzoyl peroxide and 500g of divinylbenzene evenly at room temperature, add 1000g of asphalt powder with a softening point of 270°C and a particle size of 150 mesh at a temperature of 85°C under stirring, and stir for 2 hours;

[0014] (2) Add the material mixed in step (1) into the polyvinyl alcohol dispersion at a temperature of 95°C and a mass concentration of 3%, suspend it into balls at a stirring speed of 150r / min for 1 hour, and transfer the dispersion and the balls to In the hydrothermal reaction kettle, after hydrothermal reaction at 145°C for 6.5 hours, cool down to room temperature and filter, wash the spheres with 1L deionized water and 0.5L ethanol respectively until the surface of the spheres is smooth, and obtain the original carbon spheres;

[0015] (3) Transfer the original carbon spheres obtained in step (2) to a tube furnace, and raise the temperature to 350°C at a rate of 1.5°C / min under a nitrogen atmosphere with a flow rate ...

Embodiment 2

[0017] (1) After mixing 100g of benzoyl peroxide, 650g of divinylbenzene, 1300g of styrene and 200g of diethylbenzene at room temperature, add 600g of benzoyl peroxide with a softening point of 270°C and a particle size of 200°C under stirring at a temperature of 80°C. Mesh sieved asphalt powder, stirred for 3h;

[0018] (2) Add the mixed materials in step (1) into the polyvinyl alcohol dispersion at a temperature of 95°C and a mass concentration of 5%, stir and suspend them into balls at a stirring speed of 150r / min for 1 hour, and transfer the dispersion and the balls Put it in a hydrothermal reaction kettle, conduct a hydrothermal reaction at 160°C for 3.5 hours, then cool down and filter, wash the spheres with 1L deionized water and 0.5L ethanol respectively until the surface of the spheres is smooth, and obtain the original carbon spheres;

[0019] (3) Transfer the original carbon spheres obtained in step (2) to a tube furnace, in a nitrogen atmosphere with a flow rate of...

Embodiment 3

[0021] (1) After mixing 100g of benzoyl peroxide and 1000g of divinylbenzene evenly at room temperature, add 800g of asphalt powder with a softening point of 265°C and a particle size of 150 mesh at a temperature of 90°C under stirring, and stir for 2.5 hours ;

[0022] (2) Add the mixed material in step (1) into the polyvinyl alcohol dispersion at a temperature of 85°C and a mass concentration of 5%, stir and suspend it into a ball at a stirring speed of 150r / min for 0.5h, and mix the dispersion and the ball Transfer to a hydrothermal reaction kettle, perform a hydrothermal reaction at 145°C for 3 hours, then cool down and filter, wash the spheres with 1L deionized water and 0.5L ethanol, respectively, until the surface of the spheres is smooth, and obtain the original carbon spheres;

[0023] (3) Transfer the original carbon spheres obtained in step (2) to a tube furnace, in a nitrogen atmosphere with a flow rate of 50-60L / h and an air volume fraction of 1%, at a heating rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com