ODOPB (10-(2,5-dihydroxyphenyl)-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide)-base polyphosphate flame retardant, and preparation method and application thereof

A technology based on polyphosphate and phenyl dichlorophosphate, applied in the field of polymer type phosphorus-containing flame retardant and its preparation, can solve the problem of liquid flame retardant exuding flame retardant performance, decline, use, storage and transportation Inconvenience and other problems, to achieve the effect of good flame retardant effect, wide application range and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

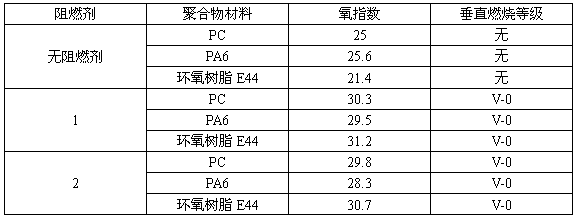

Image

Examples

Embodiment 1

[0022] Put 292g of ODOPB and 1.33g of aluminum chloride into a four-necked flask equipped with a condenser, a stirrer, a thermometer, and a protective gas inlet and outlet, pass in nitrogen, stir and raise the temperature to 140°C, and gradually add phenyl 210 grams of dichlorophosphate, keep the temperature for reaction for 1 hour, then raise the temperature to 200°C for reaction for 2 hours, until no HCl gas escapes (reaction ends). After cooling, 300ml of chloroform was added to dissolve it completely, and then poured into 8 times the volume of n-hexane for precipitation. After filtration and vacuum drying, 390g of white powdery solid was obtained, with a yield of 95%. The weight average molecular weight of the obtained flame retardant was 152085 through gel chromatography detection.

Embodiment 2

[0024] Put 324g of ODOPB and 2.72g of zinc chloride into a four-necked flask equipped with a condenser, a stirrer, a thermometer and a protective gas inlet and outlet, pass in nitrogen, stir and raise the temperature to 140°C, and gradually add phenyl 314 grams of dibromophosphate, keep the temperature for reaction for 2 hours, then raise the temperature to 210° C. and react for 3 hours until no HBr gas escapes (reaction ends). After cooling, 300ml of tetrahydrofuran was added to dissolve it completely, and then poured into 10 times the volume of deionized water for precipitation. After filtration and vacuum drying, 450g of white powdery solid was obtained, with a yield of 97%. The weight average molecular weight of the obtained flame retardant was 156552 through gel chromatography detection.

Embodiment 3

[0026] Put 389g of ODOPB and 2.19g of calcium chloride into a four-necked flask equipped with a condenser, a stirrer, a thermometer, and a protective gas inlet and outlet, pass in nitrogen, stir and raise the temperature to 140°C, and gradually add p-toluene dropwise within half an hour 225 grams of dichlorophosphate, keep the temperature for reaction for 1 hour, then raise the temperature to 220°C for reaction for 4 hours, until no HCl gas escapes (reaction ends). After cooling, 300ml of dimethyl sulfoxide was added to dissolve it completely, and then poured into 8 times the volume of anhydrous methanol for precipitation. After filtration and vacuum drying, 429g of white powdery solid was obtained, with a yield of 90%. The weight average molecular weight of the obtained flame retardant was 136088 through gel chromatography detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com