Polylactic acid blending composite and preparation method thereof

A technology of polylactic acid and its composition, which is applied in the field of polylactic acid blend composition and its preparation, can solve the problems of limited application fields, incomplete solution to the brittleness of polylactic acid, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

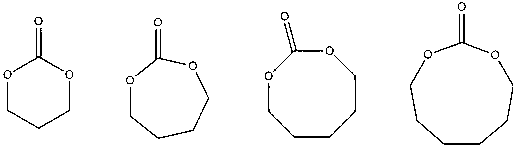

Method used

Image

Examples

Embodiment 1

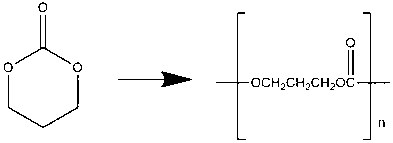

[0037]Add 12 kg of tetramethylene carbonate into a 20-liter stainless steel reactor with stirring, flush with nitrogen and replace the air three times, melt at 80-90 degrees under the protection of nitrogen, then add 0.6 grams of stannous octoate, and heat it at 130-150 degrees Polymerize for 5 hours, then vacuum (vacuum degree 1-10mmHg) at this temperature to remove unreacted tetramethylene carbonate, and use a melt pump to transport the material to a 20mm twin-screw extruder for discharge. 9.8 kilograms of polytetramethylene carbonate modifiers were obtained by underwater slitting and pelletizing, with a molecular weight of 380,000.

[0038] Mix the modified agent prepared above with polylactic acid. The mixing method can be simple physical mixing, or it can be granulated after melting and mixing with a mixer like ordinary plastics to obtain a modified polylactic acid composition. The adjustment ratio of flexibility, usually the amount of modifier is 5-50%, and the elongatio...

Embodiment 2

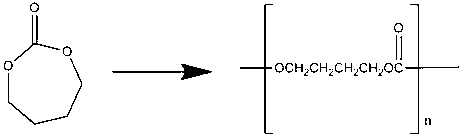

[0040] In a 1-liter glass bottle, add 300 grams of trimethylene carbonate and 200 grams of tetramethylene carbonate, replace it with high-purity nitrogen three times, add 0.5 grams of stannous octoate under nitrogen protection, and heat to 80-90 After the monomers are completely melted, stir and heat up to 120-140 degrees for 3 hours, then cool to room temperature, dissolve the product with 2000 ml of chloroform, and precipitate with 5000 ml of ethanol to obtain polytrimethylene carbonate-polytetramethylene carbonate 400 grams of modifiers, measured by GPC, have a weight-average molecular weight of 350,000 and a molecular weight distribution of 2.3, which is a rubber-like elastomer with better elasticity.

[0041] Mix the modifier prepared above with polylactic acid. The mixing method can be simple physical mixing, or it can be granulated after melting and mixing with a mixer like ordinary plastics to obtain a modified polylactic acid composition. Adjust the ratio of the degre...

Embodiment 3

[0043] In a one-liter glass bottle, add 500 grams of pentamethylene carbonate, replace it with high-purity nitrogen three times, add 0.025 grams of stannous octoate and 0.5 grams of ethylene glycol under the protection of nitrogen, heat to 100-110 degrees, and wait for a single After the body is all melted, stir and heat up to 120-140 degrees for 16 hours, then cool to room temperature, dissolve the product with 2000 milliliters of chloroform, and precipitate with 5000 milliliters of ethanol to obtain 300 grams of material. GPC measures a weight-average molecular weight of 80,000 and a molecular weight distribution of 2.3. Pentamethylene carbonate modifier.

[0044] Mix the modifier prepared above with polylactic acid. The mixing method can be simple physical mixing, or it can be granulated after melting and mixing with a mixer like ordinary plastics to obtain modified polylactic acid. Adjust according to the required flexibility. Ratio, usually the amount of modifier used is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com