Aramid fiber surface modification method

A surface modification and aramid fiber technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of unsuitable aramid fiber surface modification treatment, and achieve the effect of soft dispersion, good modification effect and stable quality of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for surface modification of aramid fibers, comprising preparation of a surface modification treatment agent, coating of the surface treatment agent, and drying treatment, wherein the preparation of the surface modification treatment agent is:

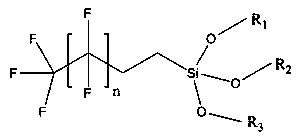

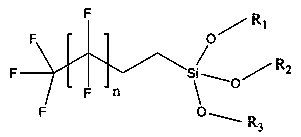

[0035] The surface modification treatment agent is directly used after being dissolved in an organic solvent with a fluorocarbon silane coupling agent of the following molecular structure formula, or directly used after being emulsified and dispersed in water with a fluorocarbon active agent:

[0036]

[0037] In the formula, n=1, R 1 , R 2 , R 3 for an alkyl group.

Embodiment 2

[0039] A method for surface modification of aramid fibers, comprising preparation of a surface modification treatment agent, coating of the surface treatment agent, and drying treatment, wherein the preparation of the surface modification treatment agent is:

[0040] The surface modification treatment agent is directly used after being dissolved in an organic solvent with a fluorocarbon silane coupling agent of the following molecular structure formula, or directly used after being emulsified and dispersed in water with a fluorocarbon active agent:

[0041]

[0042] In the formula, n=10, R 1 , R 2 , R3 for an alkyl group.

Embodiment 3

[0044] A method for surface modification of aramid fibers, comprising preparation of a surface modification treatment agent, coating of the surface treatment agent, and drying treatment, wherein the preparation of the surface modification treatment agent is:

[0045] The surface modification treatment agent is directly used after being dissolved in an organic solvent with a fluorocarbon silane coupling agent of the following molecular structure formula, or directly used after being emulsified and dispersed in water with a fluorocarbon active agent:

[0046]

[0047] In the formula, n=5, R 1 , R 2 , R 3 for an alkyl group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com