Method for preparing photoresist template and patterned ZnO nanorod array

A nanorod array and photoresist technology, which is applied in the photoengraving process of the pattern surface, optomechanical equipment, originals for optomechanical processing, etc. Asymmetric structure and other problems, to achieve the effect of simple structure, fast processing speed, and small damage to the template

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of the photoresist template comprises the following preparation steps:

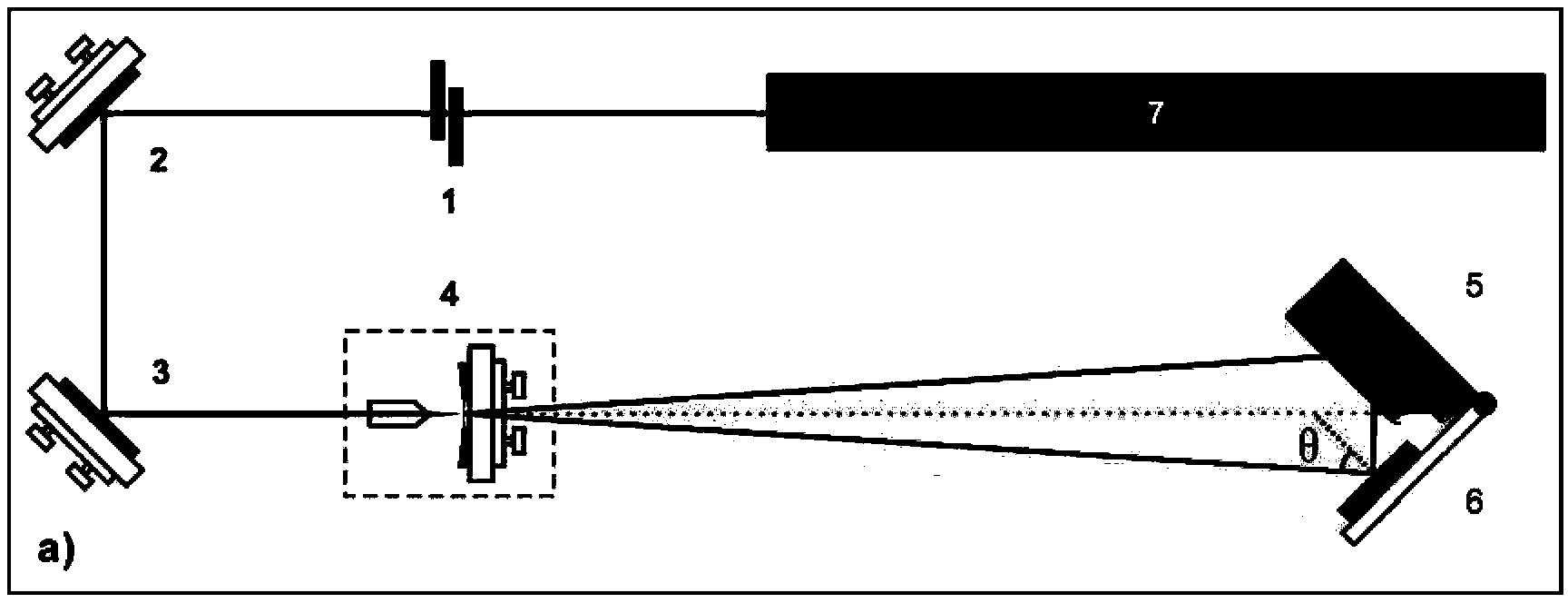

[0039] (1) Three-beam laser interference system construction: such as figure 1 As shown, a beam of 325nm laser is emitted from the He-Cd laser (7), reflected by two dielectric total reflection mirrors (2, 3), and enters the spatial filter (4) for filtering processing. The objective lens with a focal length of 2 cm and a diameter It consists of a pinhole of 5 μm, and then expands the beam by 100 cm to form a large spot with a diameter of 12 cm; the sample stage (6) is placed at an incident angle of 18.5 degrees, and the two 5×10 cm square UV-enhanced aluminum mirrors (5) have a mutual angle of 120 degrees and are perpendicular to the sample stage, the intersection of the sample stage (6) and the two mirrors is aligned with the center of the large spot; an electronic shutter (1) is placed to precisely control the exposure time.

[0040] (2) Substrate cleaning and photoresist spin coa...

Embodiment 2

[0043] The preparation method of p-GaN substrate patterned ZnO nanorod array, comprises the following steps:

[0044] (1) Three-beam laser interference system construction: such as figure 1 As shown, a beam of 325nm laser is emitted from the He-Cd laser (7), reflected by two dielectric total reflection mirrors (2, 3), and enters the spatial filter (4) for filtering processing. The objective lens with a focal length of 2 cm and a diameter It consists of a pinhole of 5 μm, and then expands the beam by 100 cm to form a large spot with a diameter of 12 cm; the sample stage (6) is placed at an incident angle of 5 degrees, and the two 5×10 cm square UV-enhanced aluminum reflectors (5) have a mutual angle of 120 degrees and are perpendicular to the sample stage, the intersection of the sample stage (6) and the two mirrors is aligned with the center of the large spot; an electronic shutter (1) is placed to precisely control the exposure time.

[0045] (2) Substrate cleaning and photo...

Embodiment 3

[0050] Si substrate patterned ZnO nanorod arrays

[0051] (1) Three-beam laser interference system construction: such as figure 1 As shown, a beam of 325nm laser is emitted from the He-Cd laser (7), reflected by two dielectric total reflection mirrors (2, 3), and enters the spatial filter (4) for filtering processing. The objective lens with a focal length of 2 cm and a diameter It consists of a pinhole of 5 μm, and then expands the beam by 100 cm to form a large spot with a diameter of 12 cm; the sample stage (6) is placed at an incident angle of 60 degrees, and the two 5×10 cm square UV-enhanced aluminum reflectors (5) have a mutual angle of 120 degrees and are perpendicular to the sample stage, the intersection of the sample stage (6) and the two mirrors is aligned with the center of the large spot; an electronic shutter (1) is placed to precisely control the exposure time.

[0052] (2) Substrate cleaning, seed layer sputtering and photoresist spin coating: 1×1cm Si substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com