Disk ceramic dielectric capacitor with vacuum sputtered multilayer metal electrode, and preparation method thereof

A multi-layer metal, vacuum sputtering technology, used in capacitors, fixed capacitors, fixed capacitor electrodes, etc., can solve problems such as affecting product reliability, damage to ceramic-intermediate structures, and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

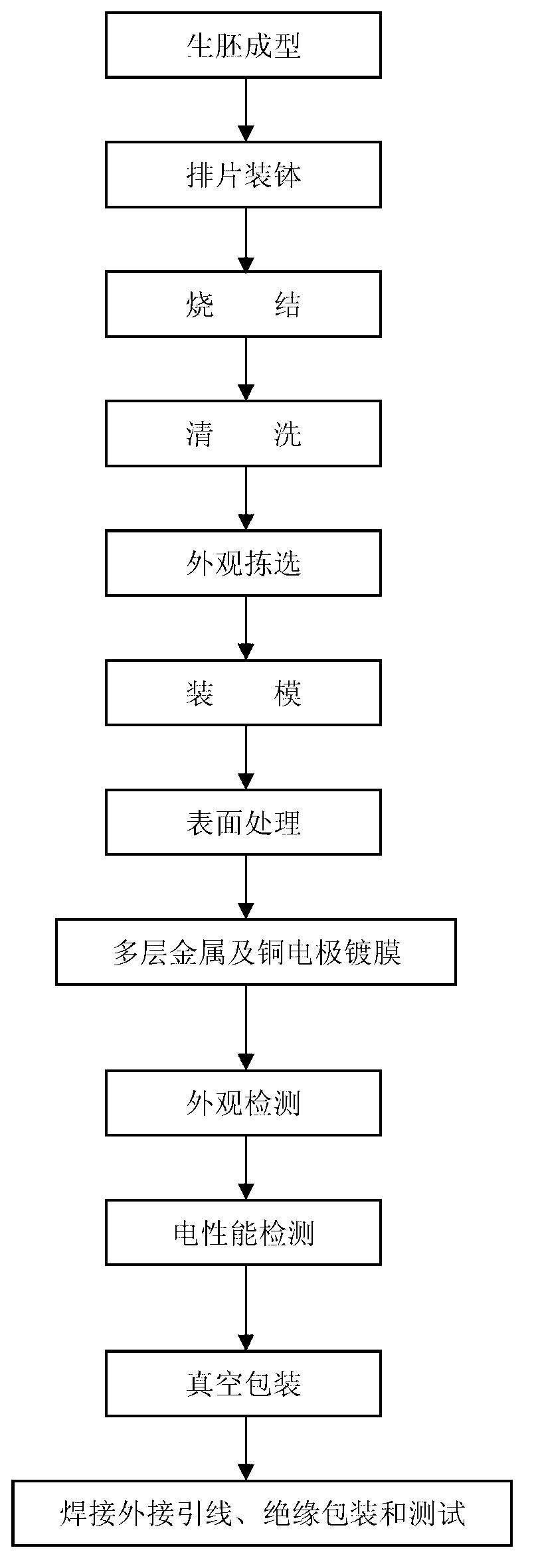

[0036] The production process of the present invention is as image 3 shown.

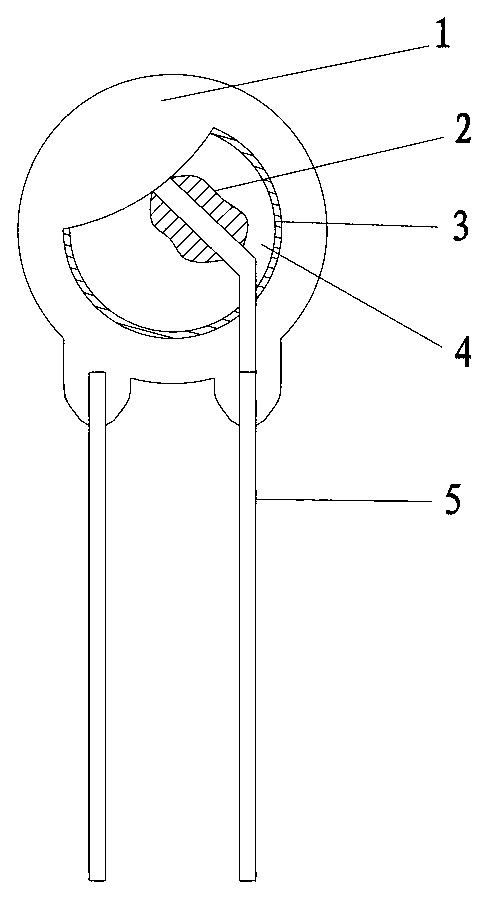

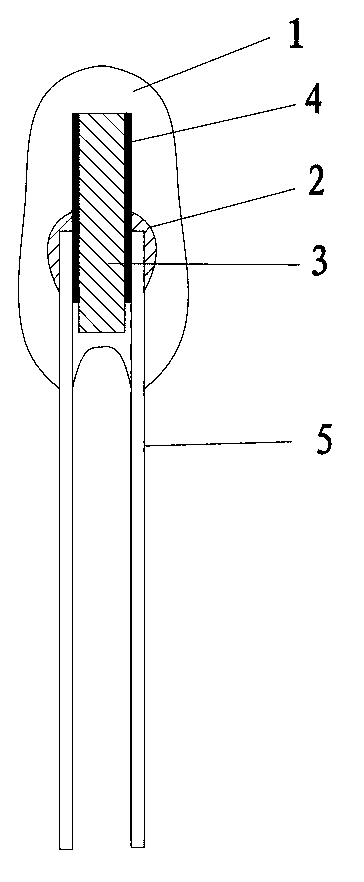

[0037] Firstly, the ceramic substrate 3 is prepared: the green body is formed, the sheets are arranged and placed in a bowl, and sintered. Clean the sintered tiles, select the appearance, and discharge them into a special mold for coating to prepare the ceramic substrate 3 . The structural design of the capacitor first designs the thickness of the ceramic substrate according to the withstand voltage level of the capacitor, then designs the diameter of the copper electrode and the diameter of the ceramic substrate according to the capacitance, and the capacitor chip size can be determined by the thickness and diameter of the ceramic substrate 3; finally Then design the corresponding lead shape and product size according to the needs of the circuit.

[0038] Again, clean and dry the ceramic substrate 3, and then use the vacuum sputtering method for coating, the metal inner layer coating metal target...

Embodiment 2

[0045] Embodiment 2 adopts the same technological process as Embodiment 1, except that the ratio of the metal inner coating metal target used is W25%-Al75% alloy metal target, and the sputtering thickness is 0.07 μm. The copper metal outer layer coating adopts Cr2%-Cu98% metal target, and the sputtering thickness is 2.5μm.

[0046] Through the above formula and steps, each group of ceramic capacitor products was prepared, and the electrical properties of the manufactured Y5V, Y5U, and Y5P products were tested respectively. The results are shown in Table 2:

[0047] Table 2

[0048] category

[0049] The result is qualified.

Embodiment 3

[0051] Embodiment 3 adopts the same process flow as Embodiment 1, except that the metal inner coating metal target used is an Al metal target, and the sputtering thickness is 0.09 μm. Copper metal outer layer coating adopts copper metal target, sputtering thickness is 3.5μm

[0052] Through the above formula and steps, each group of ceramic capacitor products was prepared, and the electrical performance of the manufactured Y5V, Y5U, and Y5P products were tested respectively. The results are shown in Table 3:

[0053] table 3

[0054] category

[0055] The result is qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com