Preparation method of mineralized refuse loaded magnetic catalyst for water treatment

A magnetic catalyst, a technology for mineralizing garbage, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Achieving the effect of low price, improved water treatment capacity and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

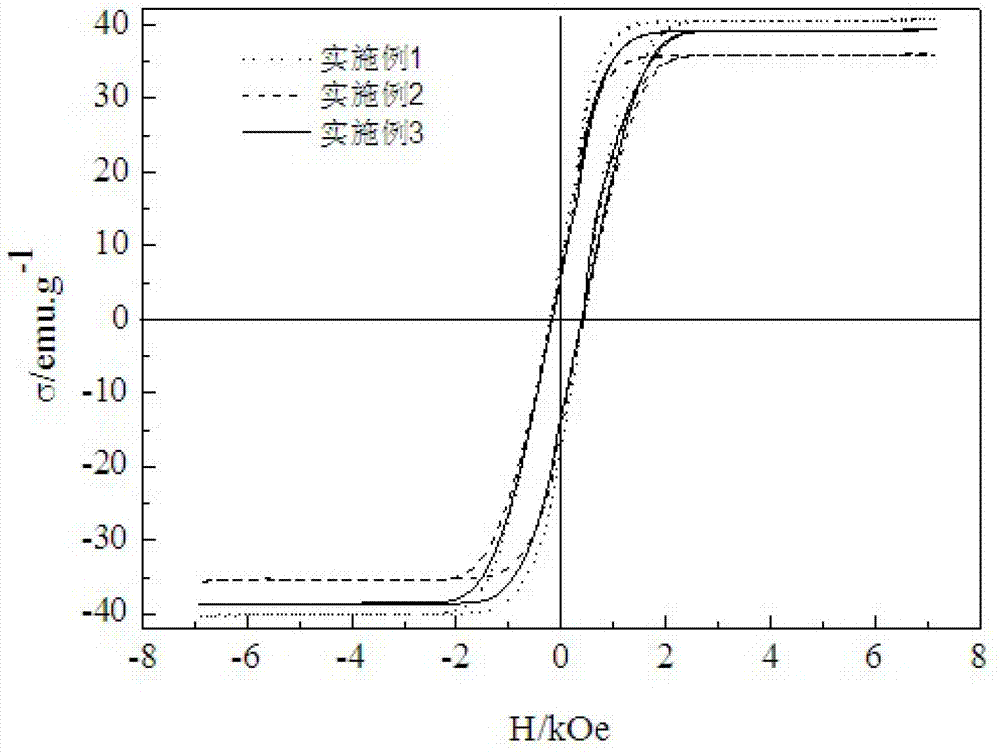

Embodiment 1

[0019] Ferric salt Fe(NO 3 ) 3 and ferrous salt FeCl 2 mixed, where Fe 3+ : Fe 2+ =2:1 (molar ratio) added to water, then add a certain amount of CuSO 4 , Cu 2+ : Fe 2+ =1:1 (molar ratio), formulated as Fe 3+ , Fe 2+ 、Cu 2+ For a mixed solution with a total concentration of 4mol / L, add the mineralized garbage that has been dried and crushed through a 150-mesh sieve into the solution. The solid-to-liquid mass ratio of the mineralized garbage to the solution is 1:5 to make a suspension, and stir for 2 hours. Place in a constant temperature water bath at 80°C, add 1mol / L KOH solution dropwise under stirring, the dosage is 1 / 3 of the volume of the mixed solution, continue stirring for 3 hours after the addition is complete; after the stirring stops, wash the precipitate with distilled water for 3 times , baked at 105°C for 3 hours, dried, and ground to obtain magnetic mineralized garbage. The iron content was 22.1% and the copper content was 8.9% according to ICP analysis...

Embodiment 2

[0023] FeCl 3 and ferrous salt FeSO 4 mixed, where Fe 3+ : Fe 2+ =2:1.5 (molar ratio) added to water, then add a certain amount of CuSO 4 , Cu 2+ : Fe 2+ =1:1.5 (molar ratio), formulated as Fe 3+ , Fe 2+ 、Cu 2+ A mixed solution with a total concentration of 0.4mol / L, add dried and crushed mineralized garbage that has passed through a 60-mesh sieve into the solution, and the solid-liquid mass ratio of the mineralized garbage to the solution is 1:25 to make a suspension, and stir for 3 hours , placed in a constant temperature water bath at 70°C, add 1.5mol / L NaOH solution dropwise under stirring, the dosage is 1 / 2 of the volume of the mixed solution, continue stirring for 4 hours after the addition is complete; after the stirring stops, wash the precipitate with distilled water 5 times, baked at 120°C for 3 hours, dried and milled to obtain magnetic mineralized garbage. The iron content was 21.5% and the copper content was 8.3% according to ICP analysis. .

[0024] Add...

Embodiment 3

[0027] FeCl 3 and ferrous salt FeSO 4 mixed, where Fe 3+ : Fe 2+ =2:1 (molar ratio) added to water, then add a certain amount of CuSO 4 or CuCl 2 , Cu 2+ : Fe 2+ =1:1.5 (molar ratio), formulated as Fe 3+ , Fe 2+ 、Cu 2+ Mixed solution with a total concentration of 2mol / L, add the mineralized garbage that has been dried and crushed through a 100-mesh sieve into the solution, the solid-liquid mass ratio of the mineralized garbage to the solution is 1:20 to make a suspension, stir for 3 hours, Place in a constant temperature water bath at 80°C, add 1.5mol / L KOH solution dropwise under stirring, the dosage is 1 / 2 of the volume of the mixed solution, and continue stirring for 4 hours after the addition is completed; after the stirring stops, wash the precipitate with distilled water for 5 The second time, it was baked at 120°C for 4 hours, dried and ground to obtain magnetic mineralized garbage. The iron content was 20.7% and the copper content was 7.5% according to ICP ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com