Automatic blank cutter for rigid plastic

A blank-cutting machine and blank-cutting technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of electromagnetic brakes, low brake belt life, hidden dangers of equipment safe operation, clutch wear, etc., to improve precision and motion stability, The effect of reducing equipment maintenance costs, good stability and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

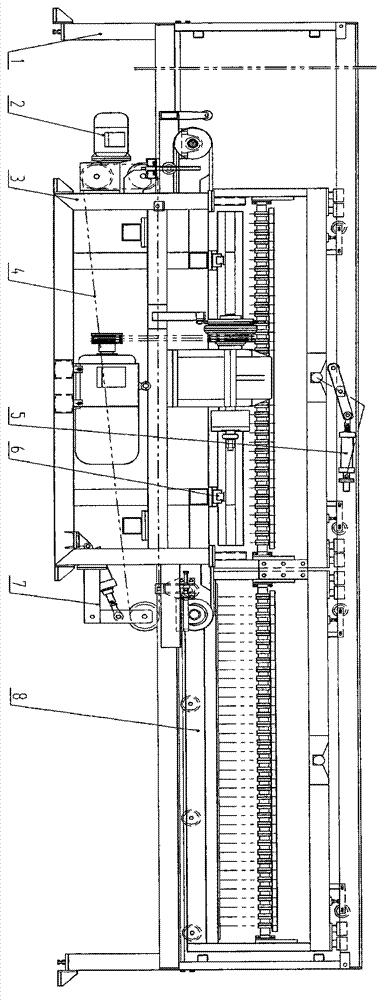

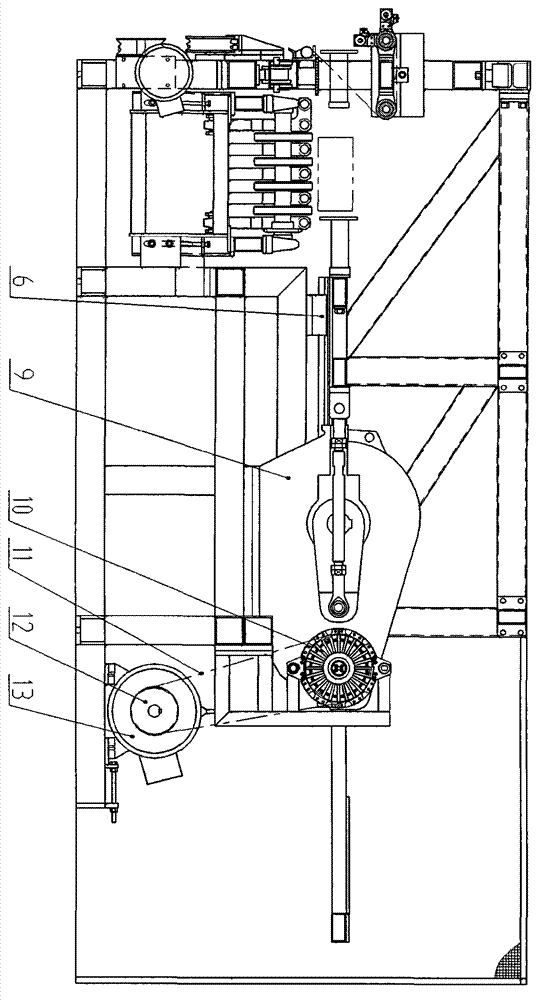

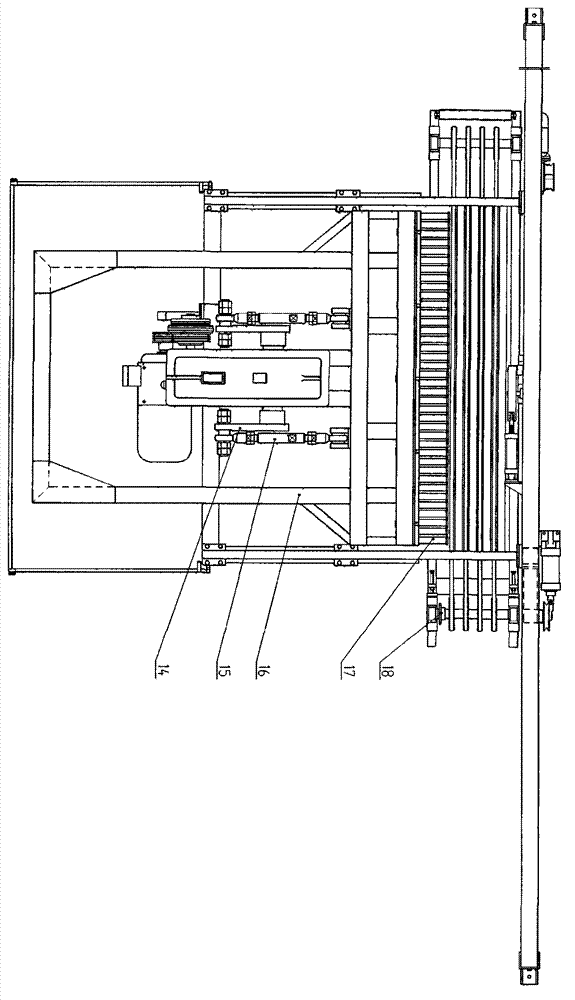

[0019] The invention is mainly composed of a machine frame, a billet cutting wire frame track frame, a main transmission device, a billet transport platform, a billet wire rack, and a billet wire rack traction device.

[0020] Frame 3, billet cut steel wire frame track frame 1 is welded by hollow square steel. The main transmission device is made of motor 13, motor wheel 12, belt 11, pneumatic clutch 10, speed reducer 9, crank 14, adjustable connecting rod 15, push base dolly 16, push base hand 17. Motor 13 output shaft is provided with motor wheel 12, and motor wheel 12 forms transmission system with the pneumatic clutch 10 that is arranged on reducer 9 input shafts through belt 11, and reducer 9 output shafts are provided with crank 14, connect adjustable connecting rod 15 one ends, The other end of the adjustable connecting rod 15 is connected to the billet pushing trolley 16. The billet pushing trolley 16 is connected with the frame 3 through the linear guide rail pair 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com