Preparation method of one-dimensional silicon nanowires with different linear densities

A technology of silicon nanowires and silicon nanowire arrays, which is applied in the field of photocatalytic materials, can solve the problems of reduced photoelectric conversion efficiency, poor photoelectric performance of photocurrent characteristics, and easy contamination of the surface, and achieves low cost, simple and convenient preparation process, The effect of simple materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Pretreatment of silicon wafers: After cutting the silicon wafers, first place them in acetone solution to clean the ultrasonic wave, clean them with deionized water, and then immerse them in HF / H with a volume ratio of 1:10. 2 After removing the thin oxide layer in a solution of O for 15 min, blow it dry with hydrogen;

[0023] 2) One-dimensional SiNWs arrays were prepared by metal-catalyzed corrosion method, which was divided into the following two steps:

[0024] The first step is to deposit silver nanoparticles: the pretreated silicon wafer is mixed with 0.14 mol / L HF and 0.01 mol / L AgNO 3 Immerse in the mixed solution for 30s;

[0025] The second step, metal-assisted etching: the silicon substrate deposited with silver nanoparticles was immersed in HF-H 2 o 2 -H 2 In the mixed etching solution with O volume ratio of 20:10:70, etch at room temperature for 30 min, 10% SiNWs were obtained;

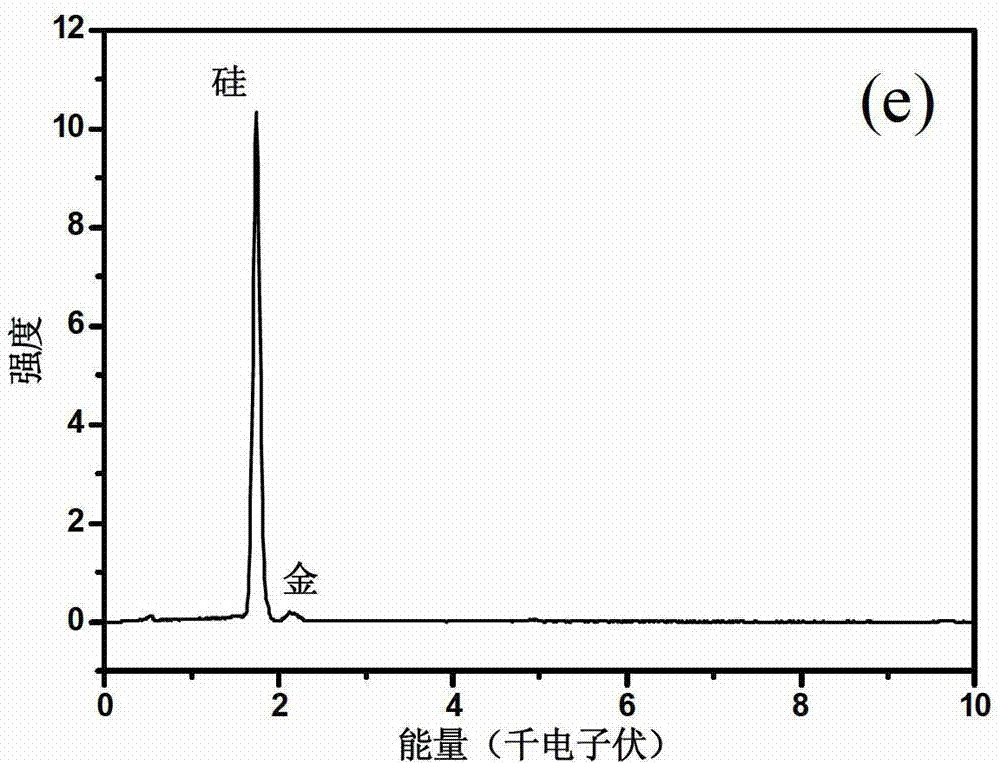

[0026] 3) Post-processing of one-dimensional SiNWs array: place the et...

Embodiment 2

[0029] 1), the pretreatment of silicon wafer (same as embodiment 1);

[0030] 2) One-dimensional SiNWs arrays were prepared by metal-catalyzed corrosion method, which was divided into the following two steps:

[0031] The first step is to deposit silver nanoparticles: the pretreated silicon wafer is mixed with 0.14 mol / L HF and 0.01 mol / L AgNO 3 Immerse in the mixed solution for 30s;

[0032] The second step, metal-assisted etching: the silicon substrate deposited with silver nanoparticles was immersed in HF-H 2 o 2 -H 2 In the mixed etching solution with O volume ratio of 20:20:60, etch at room temperature for 30 min, 20% SiNWs were obtained;

[0033] 3), one-dimensional SiNWs array post-processing (same as Example 1);

[0034] 4), sample characterization and photoelectric performance test (same as Example 1).

Embodiment 3

[0036] 1), the pretreatment of silicon wafer (same as embodiment 1);

[0037] 2) One-dimensional SiNWs arrays were prepared by metal-catalyzed corrosion method, which was divided into the following two steps:

[0038]The first step is to deposit silver nanoparticles: the pretreated silicon wafer is mixed with 0.14 mol / L HF and 0.01 mol / L AgNO 3 Immerse in the mixed solution for 30s;

[0039] The second step, metal-assisted etching: the silicon substrate deposited with silver nanoparticles was immersed in HF-H 2 o 2 -H 2 In the mixed etching solution with O volume ratio of 20:30:50, etch at room temperature for 30 min, 30% SiNWs were obtained;

[0040] 3), one-dimensional SiNWs array post-processing (same as Example 1);

[0041] 4), sample characterization and photoelectric performance test (same as Example 1).

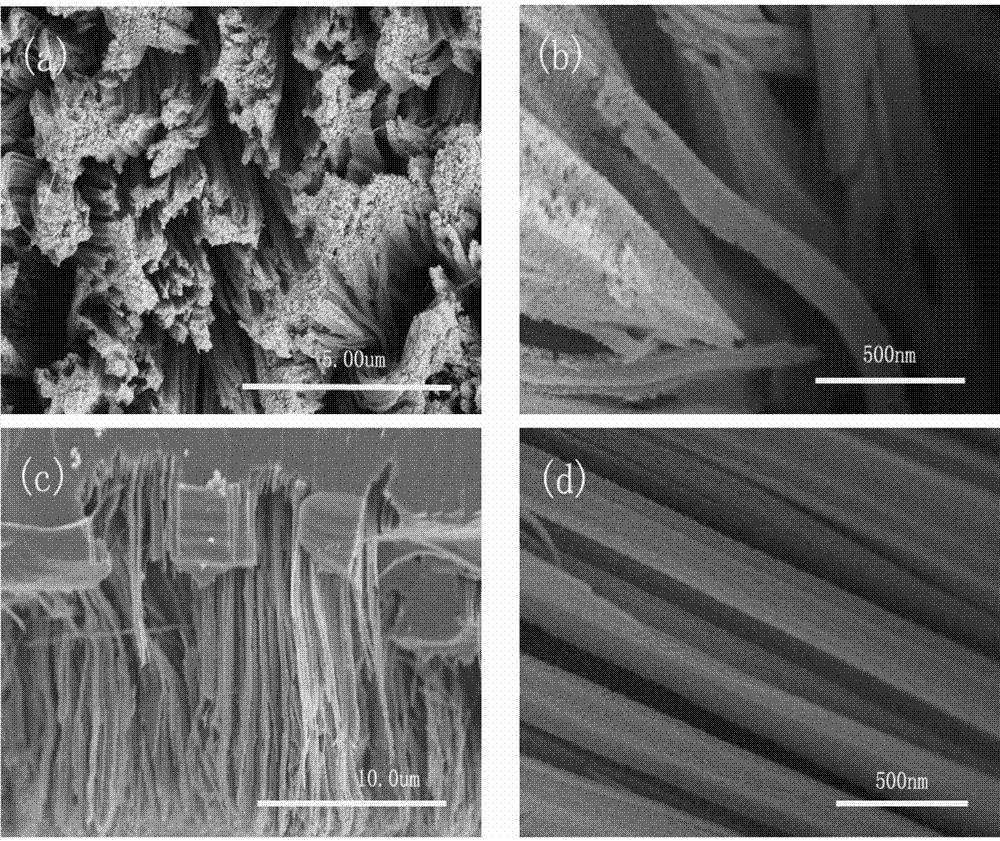

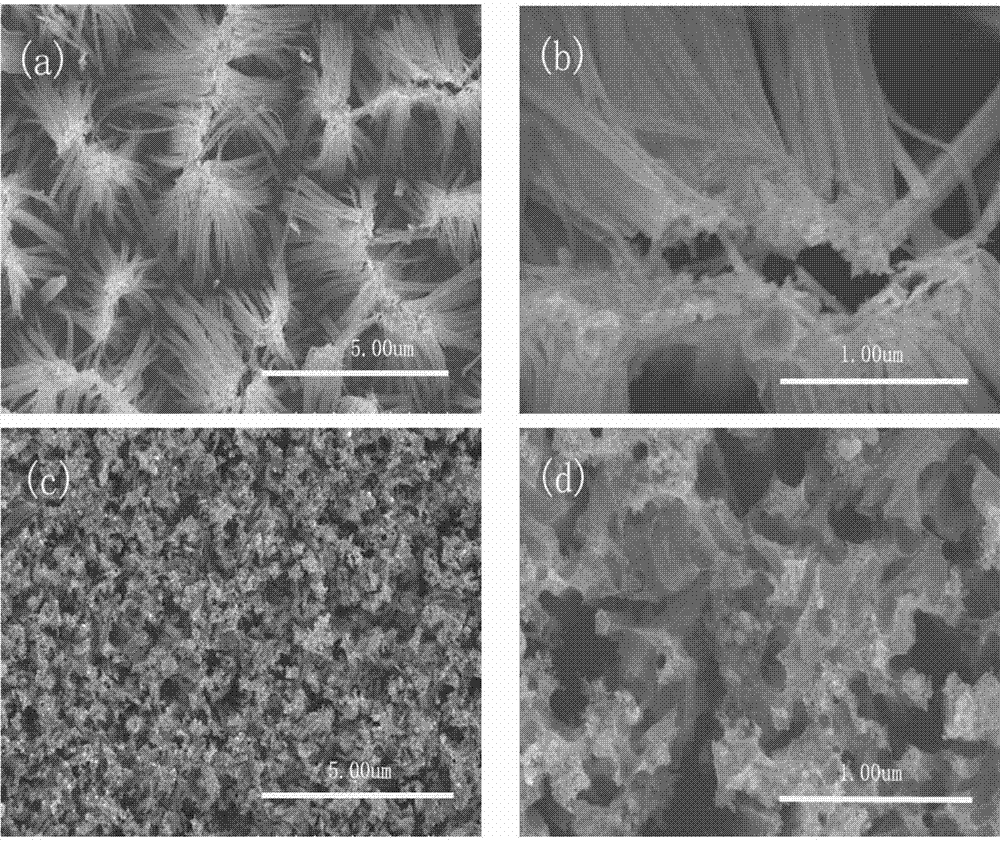

[0042] It can be seen from the SEM image that 10% H 2 o 2 The length of one-dimensional SiNWs prepared by etching is about 16 μm, and the diameter is about 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com