Nanometer boehmite and preparation method thereof

A nano-boehmite and hydrothermal reaction technology, applied in the field of boehmite, can solve the problems of difficult industrial production, poor quality stability, and few product types, so as to avoid the use of strong acid and strong alkali, save costs, eliminate The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

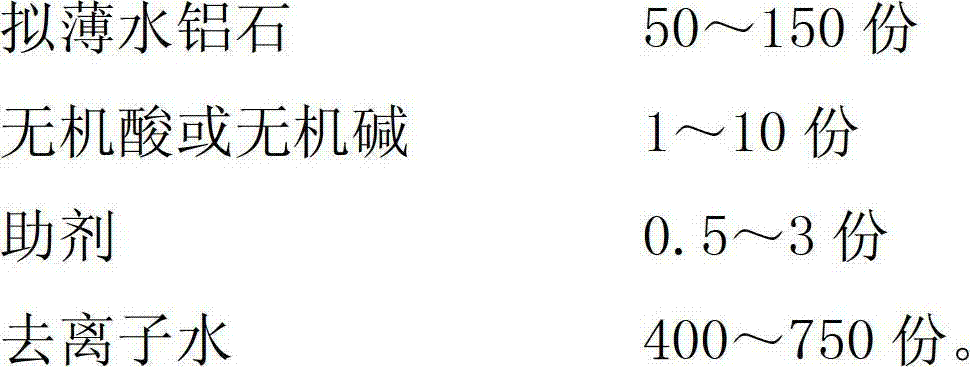

[0025] A kind of nano-boehmite adopts the following raw material ratio:

[0026]

[0027] The preparation method of the nano boehmite comprises the following steps:

[0028] (1) Add pseudo-boehmite to deionized water at room temperature, stir mechanically for 15 minutes, add nitric acid, and continue stirring for 15 minutes;

[0029] (2) Add 3-aminopropyltriethoxysilane and continue stirring for 30 minutes;

[0030] (3) Add the feed liquid into a 1000ml high-pressure reactor, raise the temperature to 190°C, and keep it warm for 3 hours;

[0031] (4) Cool the feed liquid to below 50°C, discharge the feed liquid, wash the feed liquid with deionized water until the conductivity value is less than 300 μS / cm, and spray dry to obtain white powder A.

Embodiment 2

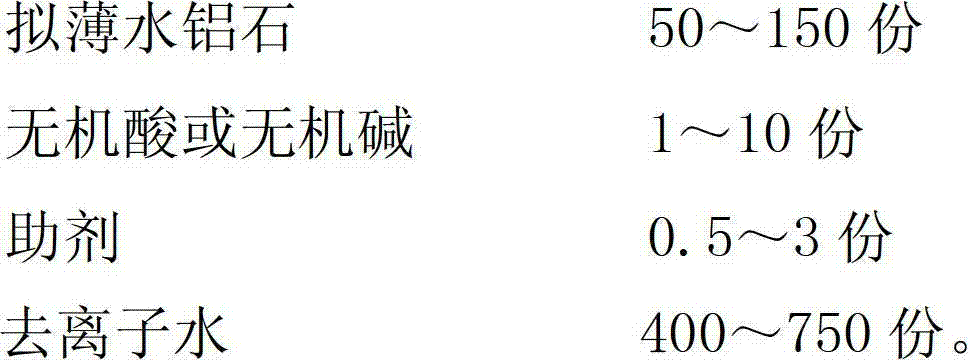

[0033] A kind of nano-boehmite adopts the following raw material ratio:

[0034]

[0035] The preparation method of the nano boehmite comprises the following steps:

[0036] (1) Add pseudo-boehmite to deionized water at room temperature, stir mechanically for 15 minutes, add acetic acid, and continue stirring for 30 minutes;

[0037] (2) Add 3-aminopropyltriethoxysilane and continue stirring for 30 minutes;

[0038] (3) Add the feed liquid into a 1000ml high-pressure reactor, raise the temperature to 210°C, and keep it warm for 5 hours;

[0039] (4) Cool the feed liquid to below 50°C, discharge the feed liquid, wash the feed liquid with deionized water until the conductivity value is less than 300 μS / cm, and spray dry to obtain white powder B.

Embodiment 3

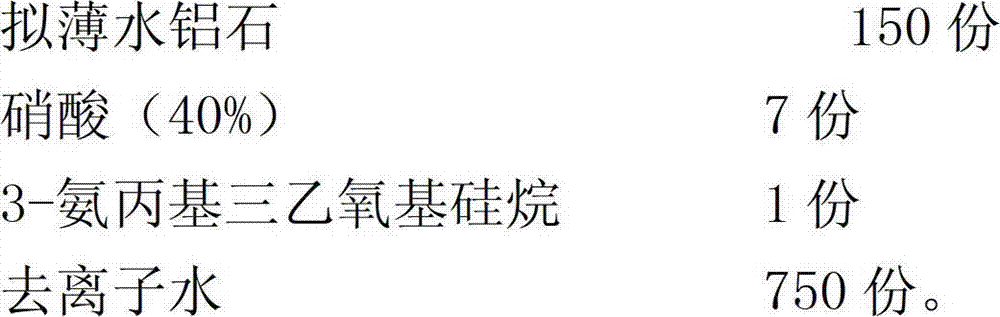

[0041] A kind of nano-boehmite adopts the following raw material ratio:

[0042]

[0043] The preparation method of the nano boehmite comprises the following steps:

[0044] (1) Add pseudo-boehmite to deionized water at room temperature, stir mechanically for 15 minutes, add sulfuric acid, and continue stirring for 30 minutes;

[0045] (2) Add sodium carbonate and continue stirring for 30 minutes;

[0046] (3) Add the feed liquid into a 1000ml high-pressure reactor, raise the temperature to 170°C, and keep it warm for 6 hours;

[0047] (4) Cool the feed liquid to below 50°C, discharge the feed liquid, wash the feed liquid with deionized water until the conductivity value is less than 300 μS / cm, and spray dry to obtain white powder C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com