Low-hydroxy black quartz tube and preparation method of low-hydroxy black quartz tube

A quartz tube and low-hydroxyl technology, applied in the field of quartz tubes, can solve the problems of insufficient pressure resistance, insufficient safety, unreasonable raw material formula, etc., and achieve the effect of ensuring quality and performance, improving compressive strength, and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a kind of low hydroxyl black quartz tube, it is made of the raw material of following percentage by weight:

[0026] Weight percent SiO 2 ≥99.95%, 98.90% of high-purity quartz sand with impurity weight content less than 20ppm;

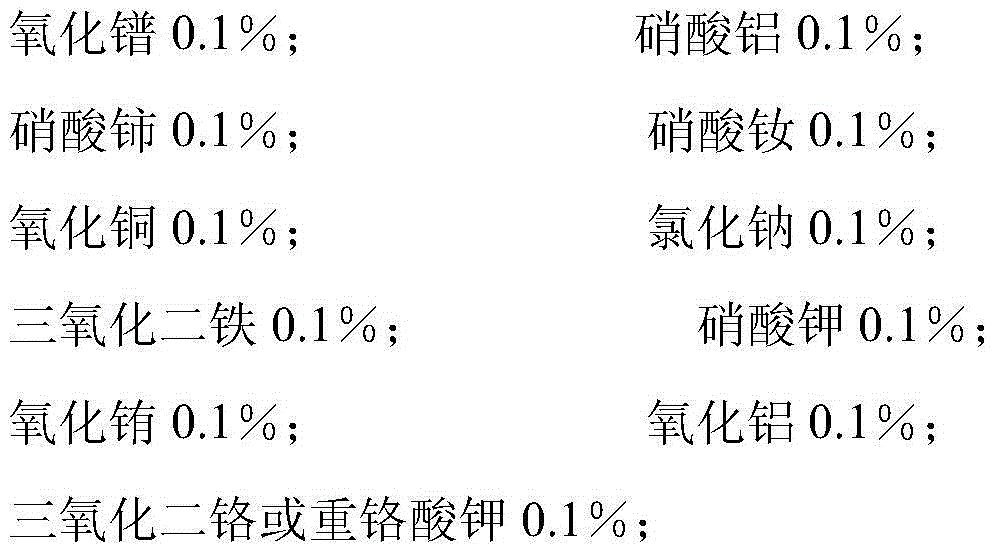

[0027] Praseodymium oxide 0.1%; Aluminum nitrate 0.1%;

[0028] Cerium nitrate 0.1%; Neodymium nitrate 0.1%;

[0029] Copper oxide 0.1%; Sodium chloride 0.1%;

[0030] Ferric oxide 0.1%; Potassium nitrate 0.1%;

[0031] Europium oxide 0.1%; Aluminum oxide 0.1%;

[0032] Chromium trioxide or potassium dichromate 0.1%.

[0033] The preparation method steps are as follows: first, the raw material high-purity quartz sand is mixed with sodium chloride, ferric oxide, potassium nitrate, aluminum oxide, dichromium oxide or potassium dichromate, praseodymium oxide, aluminum nitrate, cerium nitrate, neodymium nitrate Stir and mix at room temperature according to the weight ratio; then add copper oxide and europium oxide to high-purity ...

Embodiment 2

[0034] Embodiment 2, a kind of low hydroxyl black quartz tube, it is made of the raw material of following percentage by weight: percentage by weight SiO 2 ≥99.95%, high-purity quartz sand with impurity weight content less than 20ppm, 96.5%;

[0035] Praseodymium oxide 0.01%; Aluminum nitrate 0.5%;

[0036] Cerium nitrate 0.01%; Neodymium nitrate 0.5%;

[0037] Copper oxide 0.01%; Sodium chloride 0.5%;

[0038] Ferric oxide 0.01%; Potassium nitrate 0.5%;

[0039] Europium oxide 0.01%; Aluminum oxide 0.5%;

[0040] Chromium trioxide or potassium dichromate 0.5%.

[0041] The low-hydroxyl black quartz tube can be prepared according to a conventional quartz tube drawing method.

Embodiment 3

[0042] Embodiment 3, a kind of low hydroxyl black quartz tube, it is made of the raw material of following percentage by weight:

[0043] Weight percent SiO 2 ≥99.95%, 97.44% of high-purity quartz sand with impurity weight content less than 20ppm;

[0044] Praseodymium oxide 0.5%; Aluminum nitrate 0.01%;

[0045] Cerium nitrate 0.5%; Neodymium nitrate 0.01%;

[0046] Copper oxide 0.5%; Sodium chloride 0.01%;

[0047] Ferric oxide 0.5%; Potassium nitrate 0.01%;

[0048] Europium oxide 0.5%; Aluminum oxide 0.01%;

[0049] Chromium trioxide or potassium dichromate 0.01%.

[0050]The preparation method steps are as follows: first, the raw material high-purity quartz sand is mixed with sodium chloride, ferric oxide, potassium nitrate, aluminum oxide, dichromium oxide or potassium dichromate, praseodymium oxide, aluminum nitrate, cerium nitrate, neodymium nitrate Stir and mix at room temperature according to the weight ratio; then add copper oxide and europium oxide to high-pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com