Bioactive mineral powder containing quasi-nanometer?particles, preparation method and application thereof in dental treatment

An active mineral, bioactive technology, applied in the application of dental treatment, bioactive mineral powder, preparation field, can solve the problem of inability to accurately control the composition of bioactive glass, dentin hypersensitivity for a long time, and failure to solve pollution and other problems to achieve the effect of improving the treatment effect, shortening the treatment time and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

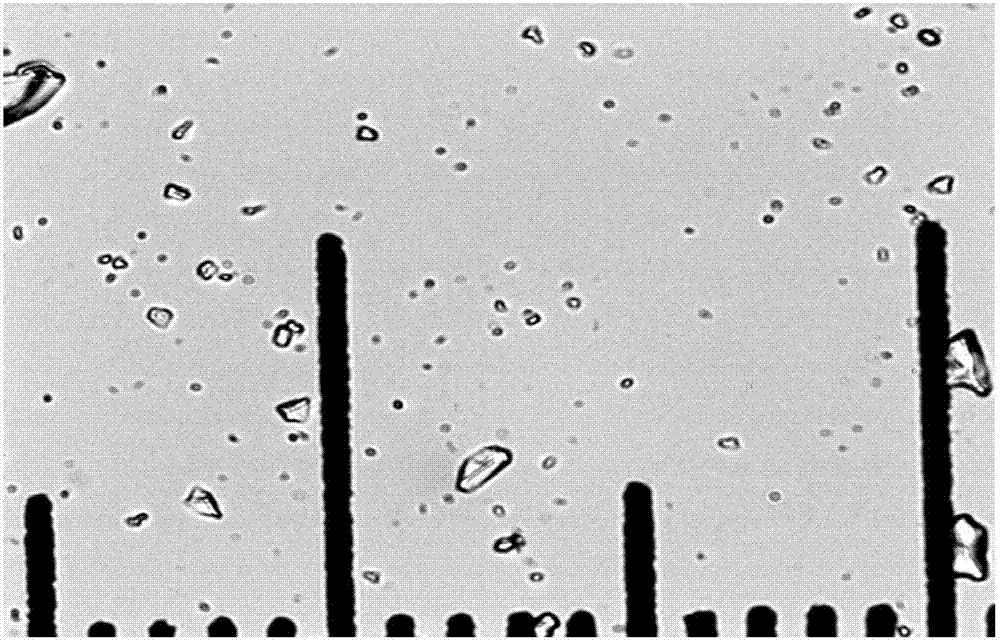

[0059] Example 1: A bioactive mineral powder containing quasi-nanoscale particles

[0060] 1. The composition of mineral powder is:

[0061] Weight percentage (%) SiO 2 45 CaO 24.5 Na 2 o 24.5 P 2 o 5 6 total 100

[0062] 2. Preparation method:

[0063] 1) Calculation of raw materials: using analytically pure silicon dioxide (SiO 2 ), calcium carbonate (CaCO 3 ), sodium carbonate (Na 2 CO 3 ), phosphorus pentoxide (P 2 o 5 ) raw materials and calculate the percentage by weight of the required raw materials according to the composition:

[0064] weight percentage Silicon dioxide (SiO 2 ) 32.93 Calcium Carbonate (CaCO 3 ) 32.02 Sodium carbonate (Na 2 CO 3 ) 30.66 Phosphorus pentoxide (P 2 o 5 ) 4.39 total 100

[0065] 2) Melt the prepared mixture in a crucible kiln at 1350°C for 2 hours and homogenize it. The melting batch is made of quartz cruc...

Embodiment 2

[0075] Example 2: A bioactive mineral powder containing quasi-nanoscale particles

[0076] 1. The composition of mineral powder is:

[0077] Weight percentage (%) SiO 2 46.1 CaO 26.9 Na 2 o 24.4 P 2 o 5 2.6 total 100

[0078] 2. Preparation method:

[0079] 1) Calculation of raw materials:

[0080] weight percentage Silicon dioxide (SiO 2 ) 33.29 Calcium Carbonate (CaCO 3 ) 34.70 Sodium carbonate (Na 2 CO 3 ) 30.13 Phosphorus pentoxide (P 2 o 5 ) 1.88 total 100

[0081] All the other steps are the same as in Example 1.

[0082] 3. Detection: The method in Example 1 is used for detection. The particle size range of the biologically active mineral powder provided in Example 2 is less than 90um, and 1wt%-5wt% of quasi-nanoparticles with a pore size in the range of 100-900nm are contained. .

Embodiment 3

[0083] Example 3: A bioactive mineral powder containing quasi-nanoscale particles

[0084] 1. The composition of mineral powder is:

[0085] Weight percentage (%) SiO 2 55.1 CaO 22.2 Na 2 o 20.1 P 2 o 5 2.6 total 100

[0086] 2. Preparation method:

[0087] 1) Calculation of raw materials:

[0088] weight percentage Silicon dioxide (SiO 2 ) 41.84 Calcium Carbonate (CaCO 3 ) 30.10 Sodium carbonate (Na 2 CO 3 ) 26.09 Phosphorus pentoxide (P 2 o 5 ) 1.97 total 100

[0089] All the other steps are the same as in Example 1.

[0090] 3. Detection: The method in Example 1 is used for detection. In this embodiment, the particle size range of the bioactive mineral powder is less than 90um, which contains 1wt%-10wt% of quasi-nanoparticles with a pore size in the range of 100-900nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com