Partially-chilled dry coal powder or coal water slurry gasification system and gasification process

A gasification system and dry coal powder technology, applied in the direction of granular/powdered fuel gasification, chemical industry, petroleum industry, etc. Consumption and other problems, to achieve the effect of recycling, improving energy utilization, omitting chilling compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to better understand this solution, the following is a detailed description through specific implementation cases and in conjunction with the accompanying drawings:

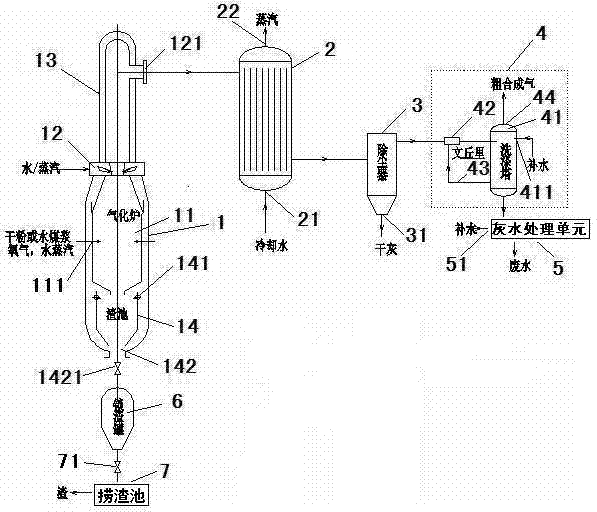

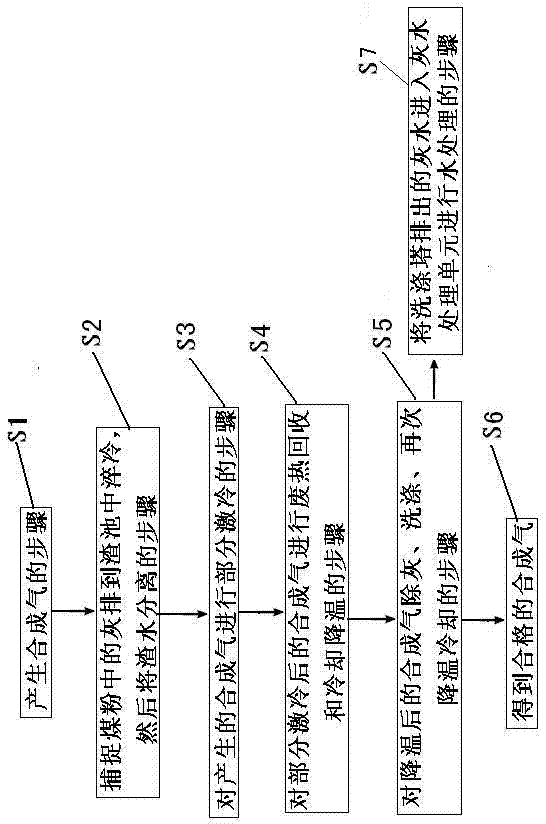

[0040] see figure 1 , a partially chilled dry coal powder or coal-water slurry gasification system of the present invention, comprising a gasifier 1, a heat recovery device 2, a dust removal device 3, a washing unit 4, and a gray water treatment unit 5 sequentially connected through pipelines .

[0041] The gasifier 1 includes a furnace 11, a cooling device 12 coaxially arranged on the top of the furnace, and a syngas delivery part 13 connected to the output end of the cooling device; the upper and lower parts of the furnace are conical Shaped structure with a straight wall in the middle. The hearth is provided with at least one nozzle 111 , and the hearth of the gasification furnace in this embodiment is provided with 4 to 6 nozzles, arranged symmetrically. An exhaust port 121 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com