Production process for producing gamma-cyclodextrin by biological method

A production process, cyclodextrin technology, applied in the production process field of γ-cyclodextrin by biological method, can solve the problems of lack of γ-cyclodextrin production process, low solubility of β-cyclodextrin, low water solubility, etc. , to achieve the effects of low cost, release of product inhibition, and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Raw material pretreatment:

[0027] According to the concentration of 10%, the potato starch is slurried, and stirred at 65°C for 10 minutes to make the starch granules fully absorb water and swell;

[0028] Enzymatic production process:

[0029] After pretreatment, set the temperature to 50°C, adjust the pH to 10.0, add γ-CGTase at a rate of 6 units per gram of starch, then add 5% (w / v) cyclododecanone, and fully react for 9 hours ;

[0030] The extraction process of γ-cyclodextrin:

[0031] After killing the enzyme in a boiling water bath, filter the reaction liquid, wash the filter cake 2-3 times with distilled water, collect the filter cake, including the precipitate formed by cyclododecanone and γ-cyclodextrin and unreacted starch; Redissolve in water, and then use steam distillation to remove cyclododecanone. After the distillation is over, filter the distillate to remove unreacted starch to obtain an aqueous solution of γ-cyclodextrin; evaporate and concentrat...

Embodiment 2

[0037] Raw material pretreatment:

[0038] Same as Example 1

[0039] Enzymatic production process:

[0040] After pretreatment, set the temperature to 40°C, adjust the pH to 10.0, add γ-CGTase at a rate of 3 units per gram of starch, and then add 4% (w / v) cyclododecanone to the reaction system, fully Reaction for 10 hours;

[0041] The extraction process and detection method of γ-cyclodextrin:

[0042] Same as Example 1

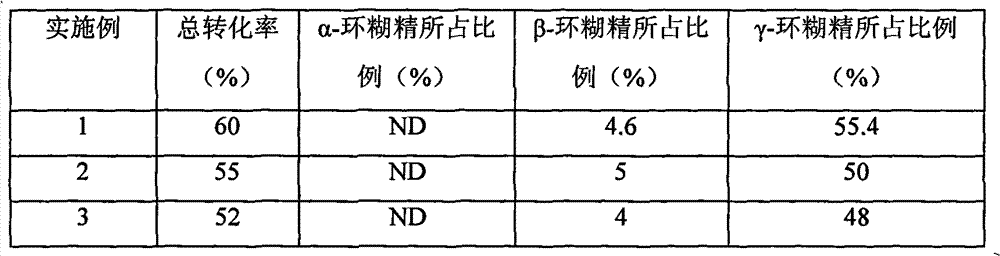

[0043] The results are shown in Table 1. The total conversion rate of starch is as high as 55%, the proportion of γ-cyclodextrin in the product is 50%, and the proportion of β-cyclodextrin is 5%.

Embodiment 3

[0045] Raw material pretreatment:

[0046] Same as Example 1

[0047] Enzymatic production process:

[0048] After pretreatment, set the temperature to 60°C, adjust the pH to 10.0, add γ-CGTase at a rate of 10 units per gram of starch, and then add 2.6% (w / v) cyclododecanone to fully react for 8 Hour;

[0049] The extraction process and detection method of γ-cyclodextrin:

[0050] Same as Example 1

[0051] The results are shown in Table 1. The total conversion rate of starch is as high as 52%, the proportion of γ-cyclodextrin in the product is 48%, and that of β-cyclodextrin is 4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com