Device and method for inducing orientation arrangement of montmorillonoid in polyethylene by using electric field

A technology of electric field induction and orientation alignment, applied in the direction of circuits, electrical components, insulators, etc., to achieve the effect of firm device structure, simple device, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

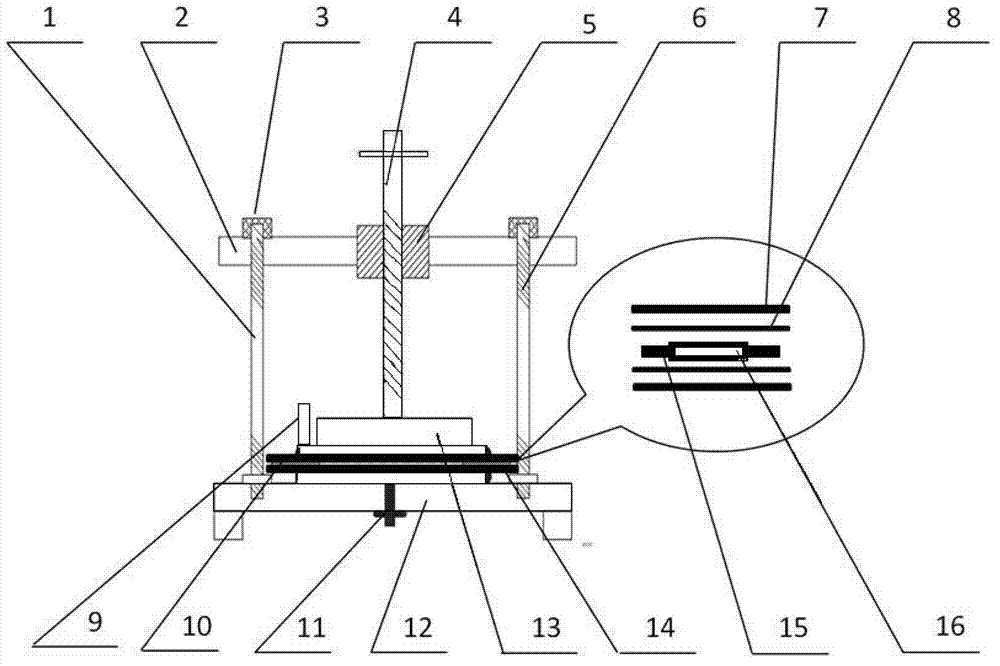

[0056] Include the following steps:

[0057] Step 1: Prepare the sample container: take a granular polyethylene / montmorillonite composite material with a montmorillonite content of 1% as a sample, place it in the through hole, cover the upper and lower sides with a layer of polyester film, and place it on a flat vulcanizer Heat pressing for 30 minutes at a molding temperature of 150°C. The thickness of the sample cavity 15 is 0.5 mm, and the thickness of the sample after hot pressing is 0.75 mm;

[0058] Step 2: Install the sample and wire: After pressing, attach a layer of epoxy glass fiber board to the surface of the upper and lower polyester films, and then put the sample holder between the upper electrode and the lower electrode; operation assistance Press the mechanism so that the upper electrode, the lower electrode, the epoxy glass fiber board, the polyester film and the sample are in close contact; at this time, put the integrated orientation arrangement device into t...

Embodiment 2

[0064] The difference from Example 1 is that if the electrical dendrite induction test is to be performed on the sample after electric field-induced orientation, in order to facilitate the later insertion of a needle electrode with a diameter of 4 mm in the sample, an iron plate with a thickness of 20 mm is used to make the sample Cavity, the thickness of the sample after hot pressing is 23mm. Parameter selection for other operations:

[0065] In step 1, hot press for 10 minutes at a molding temperature of 180° C. on a flat vulcanizer;

[0066] In step 3, adjust the temperature of the aging box to 250°C and keep it for 10 minutes, so that the sample 16 reaches a molten state;

[0067] In step 4, keep the heating temperature constant, and apply a power frequency AC electric field with a strength of 20kV / mm to the sample through the voltage application device for 10 minutes.

Embodiment 3

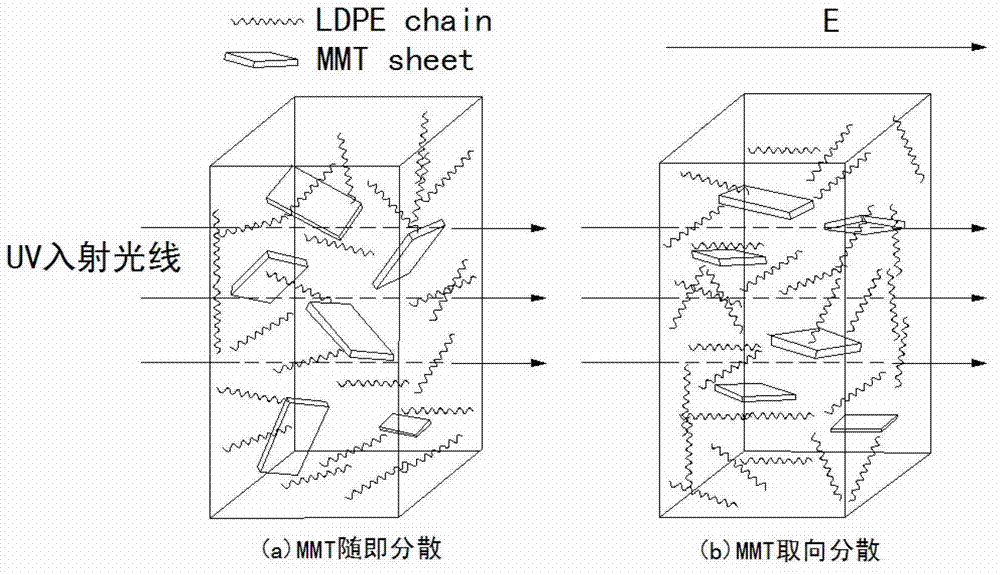

[0069] In order to obtain different electric tree inhibition effects, the addition amount of montmorillonite was changed to 3%. At this time, the content of montmorillonite increases, the viscosity of polyethylene / montmorillonite composite increases, and the viscous resistance of montmorillonite in the process of electric field induced orientation increases. In order to keep the effect of the orientation of the montmorillonite induced by the electric field unchanged, the heating temperature was increased to 200°C and 250°C in order to reduce the viscosity of the composite material and make the orientation of the montmorillonite reverse smoothly. Parameter selection for other operations:

[0070] In step 1, hot press for 22 minutes at a molding temperature of 155° C. on a flat vulcanizer;

[0071] In step 3, adjust the temperature of the aging box to 220°C and keep it for 15 minutes to make the sample reach a molten state;

[0072] In step 4, keep the heating temperature cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com