Method for forming metal silicide

A metal silicide and silicon substrate technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as increased leakage current, poor quality of metal silicide formation, and increased device resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

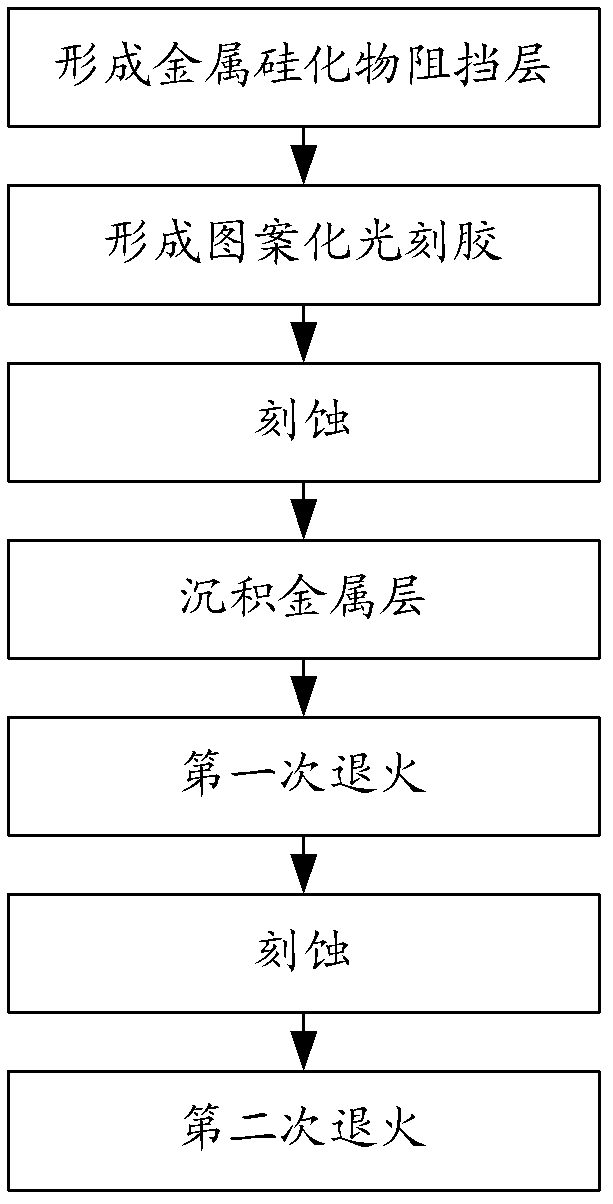

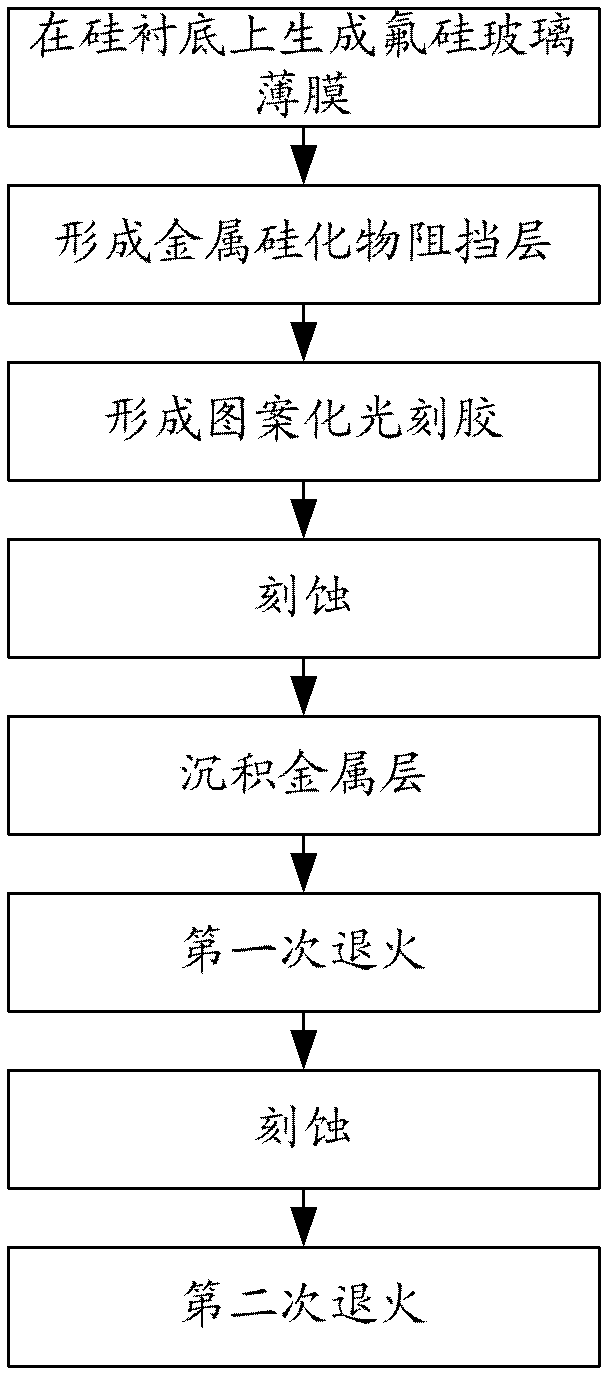

[0030] figure 2 It is a flow chart of a metal silicide forming method of the present invention, such as figure 2 As shown, the main steps of this method include:

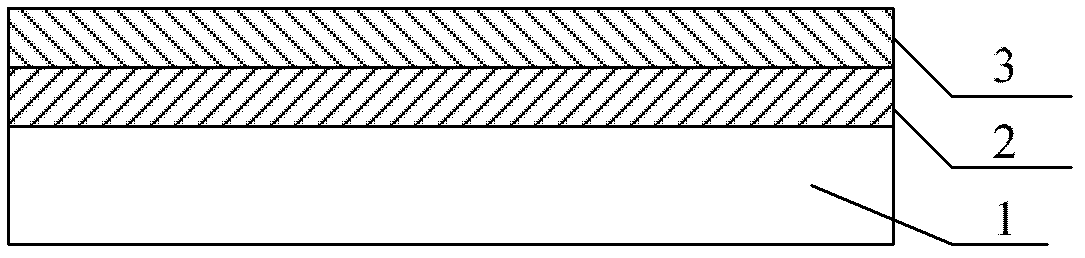

[0031] Deposit a layer of fluorosilicate glass film on the silicon substrate as a buffer layer;

[0032] Depositing a metal silicide barrier layer on the fluorosilicate glass thin film buffer layer;

[0033] forming a patterned photoresist on the metal silicide barrier layer corresponding to the predetermined area where the silicide needs to be generated on the silicon substrate;

[0034] Etching by using the patterned photoresist as a mask to expose a predetermined area on the silicon substrate where metal silicide needs to be generated and remove t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com