In-situ chemical oxidation restoration method for chlorinated olefin-polluted soil and underground water

An in-situ chemical oxidation and chlorinated olefin technology, applied in the restoration of contaminated soil, oxidized water/sewage treatment, etc., can solve the problems of low utilization rate of oxidants, large non-selective consumption, etc., achieve good treatment effect, no The effect of secondary pollution and short repair period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

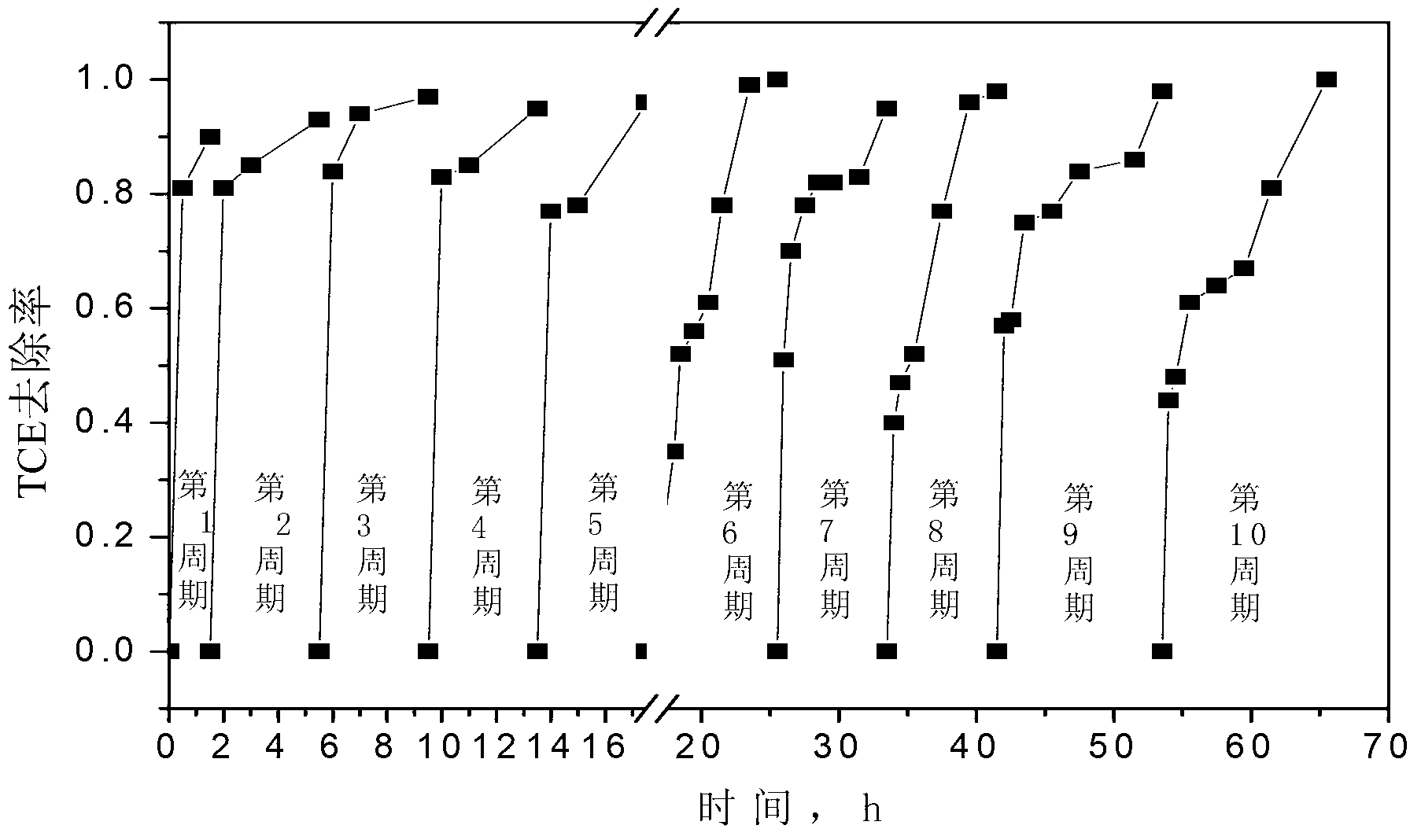

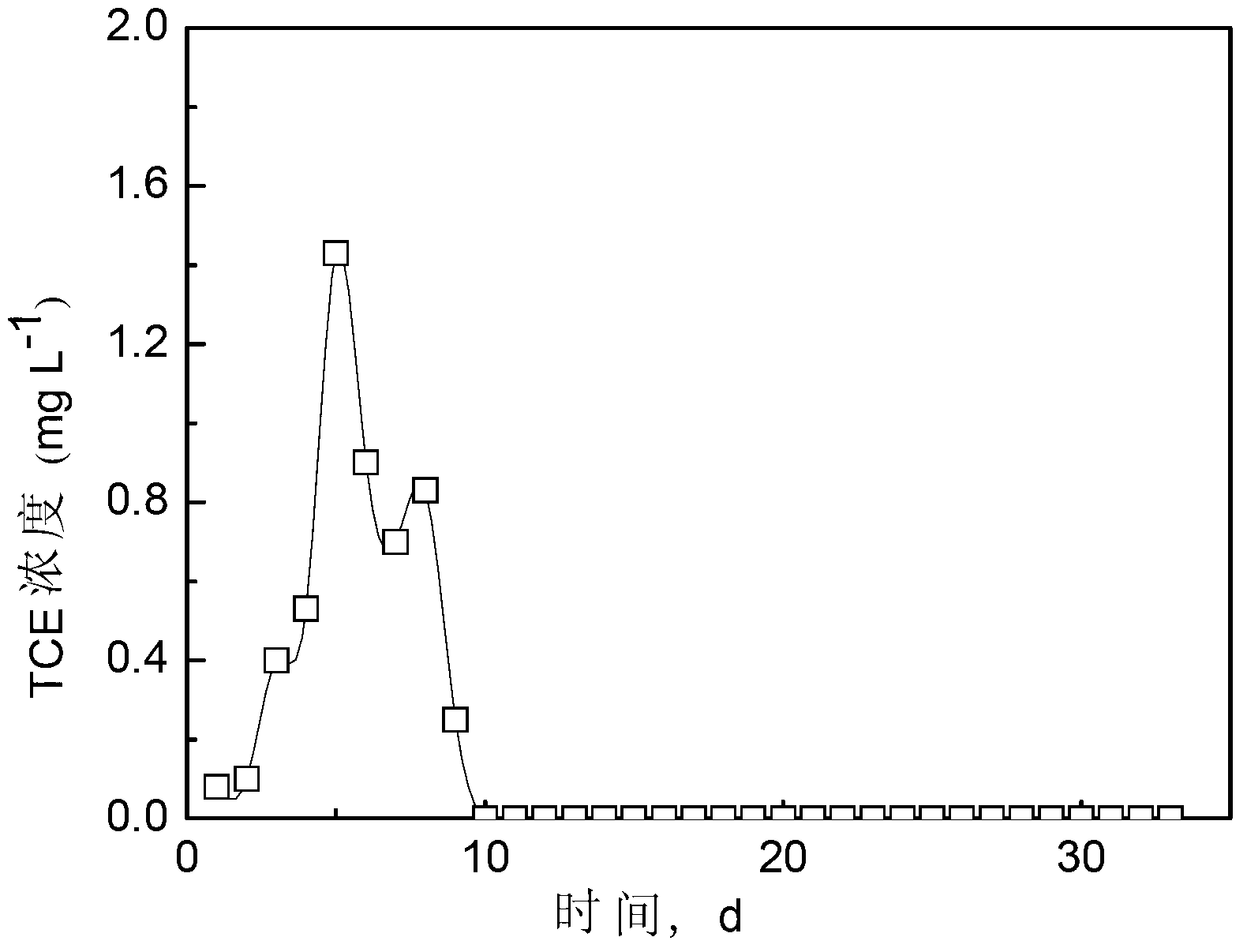

[0016] Measure the TCE solution with an initial concentration of about 10mg / L in a 120.00mL conical flask, adjust the pH value to about 6.8 with 0.1mol / L hydrochloric acid solution and 0.1mol / L NaOH solution, and add 1.8g compound permanganate Potassium sustained-release body (both ends of the slow-release body are sealed with paraffin, containing 0.5g KMnO 4 ), oxidize, oscillate at a constant temperature of 25°C, make the coated potassium permanganate fully contact with TCE, take samples regularly, quench with sodium thiosulfate to prevent potassium permanganate from continuing to react with TCE, and finally mix the sample with 0.45 Filter through a μm water-based filter membrane into an autosampler bottle and put it into a liquid chromatograph to measure the remaining TCE concentration. To study the long-term effect of compound potassium permanganate slow-release body to remove TCE, such as figure 1 shown. Potassium permanganate sustained release for 10 cycles. After 10 ...

Embodiment 2

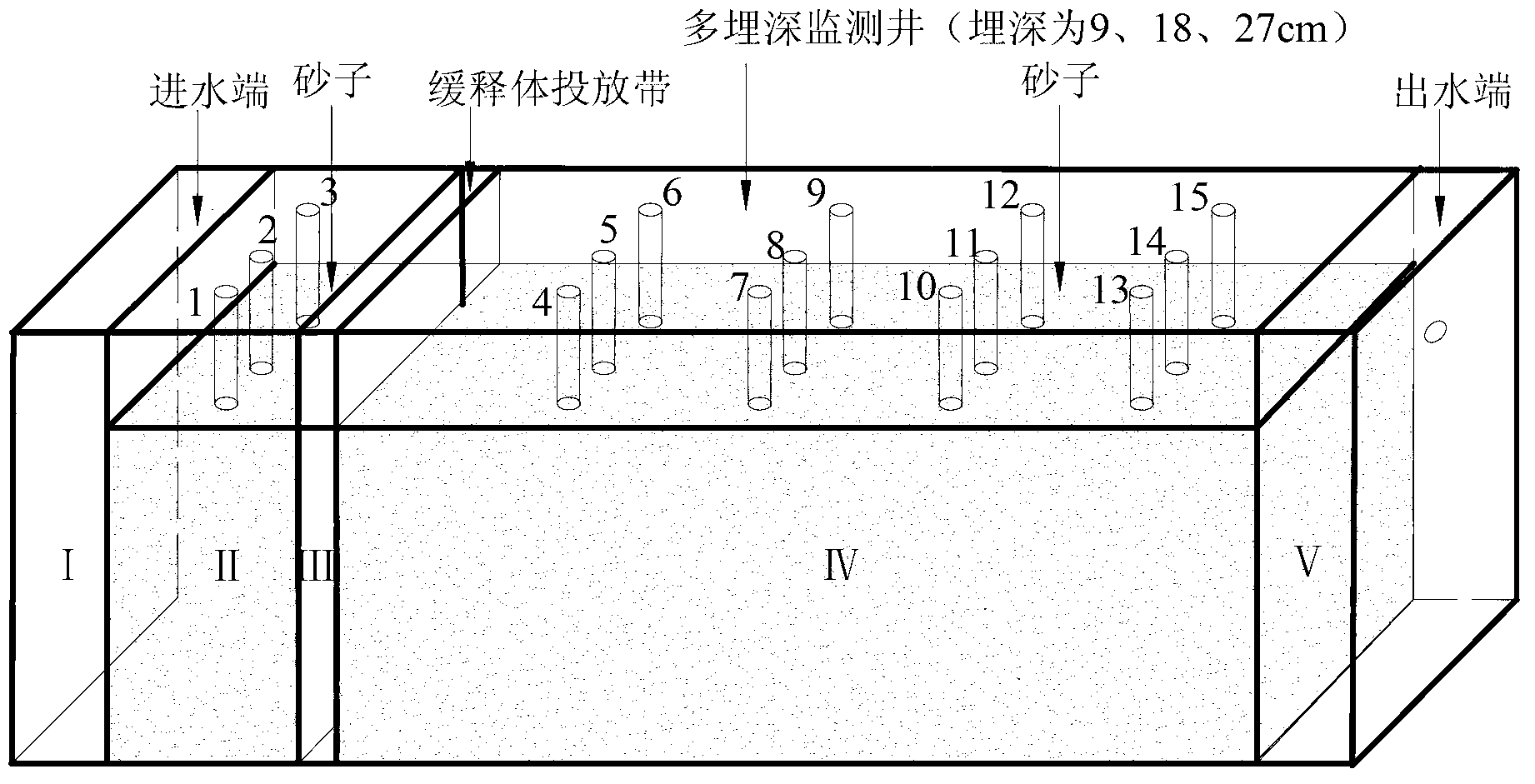

[0018] Cooperate figure 2 As shown, the total length of the reaction tank is 140cm, the width is 40cm, and the height is 45cm. The material is ordinary glass. The entire reaction tank is divided into five functional areas:

[0019] (1) Zone I is the water inlet pool, with a size of 10×40×45cm;

[0020] (2) Zone II is a simulated aquifer polluted area with a size of 20×40×45cm, filled with 40-70 mesh silica sand, and the filling height is 35cm. The basic properties of silica sand are shown in Table 4-2;

[0021] (3) Area III is a chemical reaction wall (PRB), with a size of 4×40×45cm, made of acrylic board, and 16 holes with a diameter of 8mm on each side wall. The entire PRB can be pulled out to replace the medium inside, and the operation is simple and convenient, thus solving the problem of replacing the active medium when the PRB fails.

[0022] (4) Area IV is a sandy soil area with a size of 96×40×45cm, filled with 40-70 mesh silica sand, and the filling height is 35c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com