Preparation method for water-soluble fertilizer through high tower melt granulation

A water-soluble fertilizer, melt granulation technology, applied in the direction of fertilizer form, fertilizer mixture, fertilization device, etc., can solve the problems of high-tower water-soluble fertilizer, high water-insoluble content, increased water-insoluble content, etc., to achieve reduction Production of water-insoluble matter, fertilizer smoothness, and cost-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

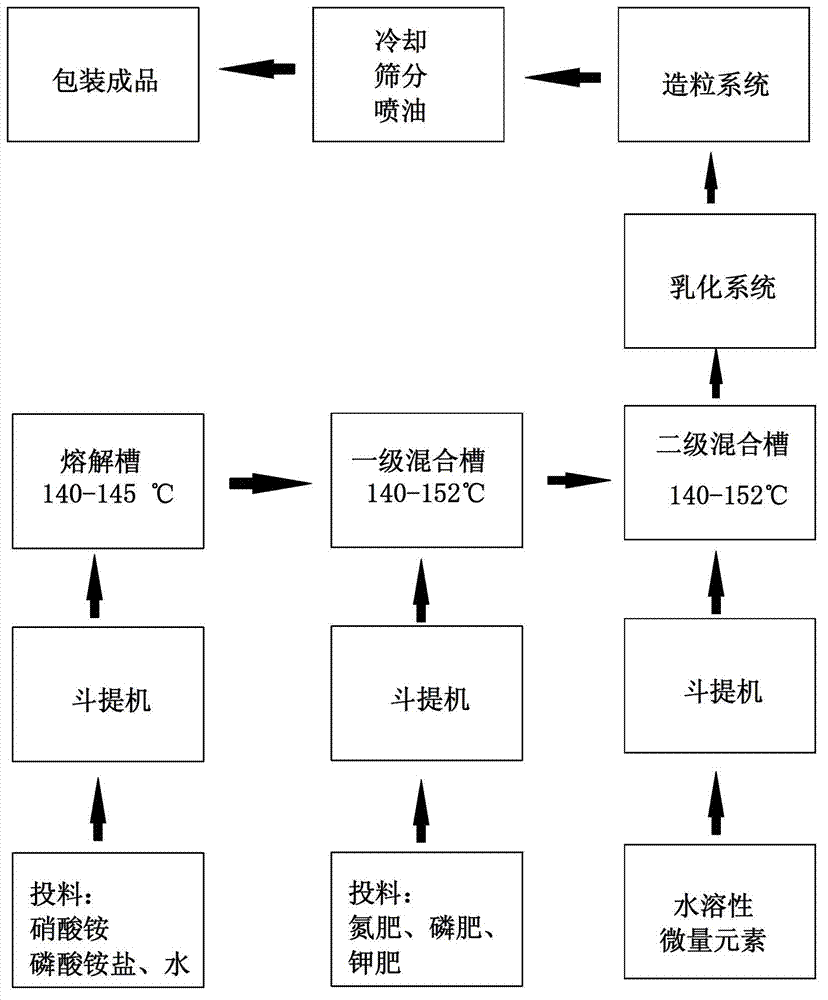

[0032] A preparation method of high tower melt granulation water-soluble fertilizer, the method comprises the steps of:

[0033] a. Add 0.6 tons of ammonium nitrate with a water-insoluble content below 0.8% and 2.9 tons of ammonium nitrate-containing mixture into the melting tank through a hoist, and add 1 ton of monoammonium phosphate with a water-insoluble content below 2.0%, Melt at a temperature of 140°C-145°C;

[0034] b. The ammonium nitrate and monoammonium phosphate eutectic slurry produced in step a are overflowed to the mixing system, and sulfuric acid with a water-insoluble content of less than 0.8% is added through the elevator in the primary and secondary mixing tanks of the mixing system After 0.65 tons of ammonium, 1.9 tons of monoammonium phosphate with a water-insoluble content of less than 2.0%, 2.85 tons of potassium sulfate with a water-insoluble content of less than 1.0%, and 0.1 tons of magnesium sulfate monohydrate, a water-soluble trace element containi...

Embodiment 2

[0038] A preparation method of high tower melt granulation water-soluble fertilizer, the method comprises the steps of:

[0039] a. Add 0.7 tons of ammonium nitrate with a water-insoluble content below 0.8% and 2.3 tons of ammonium nitrate-containing mixture into the melting tank through a hoist, and add 1.2 tons of monoammonium phosphate with a water-insoluble content below 2.0%, Melt at a temperature of 140°C-145°C;

[0040] b. The ammonium nitrate and monoammonium phosphate eutectic slurry produced in step a are overflowed to the mixing system, and sulfuric acid with a water-insoluble content of less than 0.8% is added through the elevator in the primary and secondary mixing tanks of the mixing system After 0.4 tons of ammonium, 2 tons of monoammonium phosphate with a water-insoluble content of less than 2.0%, 1.65 tons of potassium sulfate and 1.65 tons of potassium nitrate with a water-insoluble content of less than 1.0%, and 0.1 tons of water-soluble trace element borax ...

Embodiment 3

[0044] A preparation method of high tower melt granulation water-soluble fertilizer, the method comprises the steps of:

[0045] a. Add 0.6 tons of ammonium nitrate and 2.9 tons of ammonium nitrate-containing mixture with a water-insoluble content of less than 0.8% into the melting tank through an elevator, and add 20kg of water to melt at a temperature of 140°C-145°C ;

[0046] b. The ammonium nitrate-containing eutectic slurry produced in step a is overflowed to the mixing system, and 0.65 tons of ammonium sulfate with a water-insoluble content of less than 0.8% is added through a hoist in the primary and secondary mixing tanks of the mixing system 2.9 tons of monoammonium phosphate with a water-insoluble content of less than 2.0%, 2.85 tons of potassium sulfate with a water-insoluble content of less than 1.0%, and 0.1 ton of zinc sulfate monohydrate, a water-soluble trace element containing zinc compounds, at 145°C- Mix evenly at a temperature of 152°C;

[0047] c. sending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com