Cyclohexanol oxidation method

A technology of cyclohexanol and oxidant, applied in the field of cyclohexanol oxidation, can solve the problems of complex process, polluted target product yield, long time consumption, etc., and achieves the effects of simple process, high selectivity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

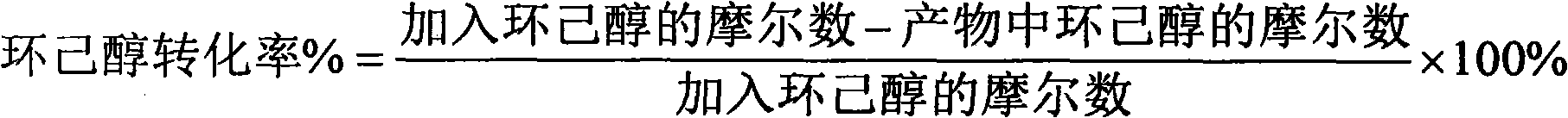

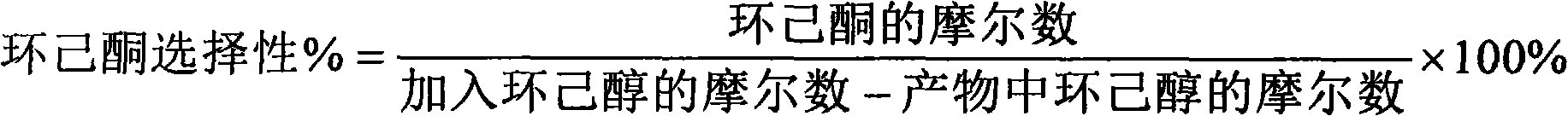

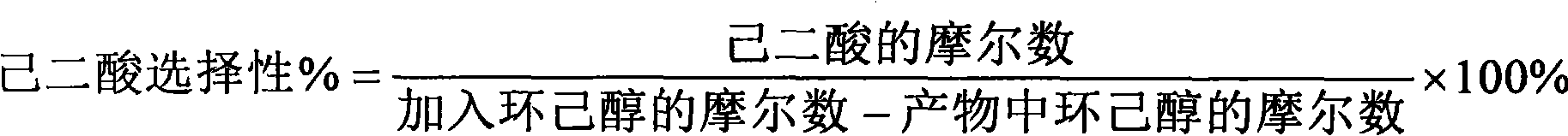

[0036] At a temperature of 60°C and a pressure of 0.5 MPa, using a mixed gas of ozone and oxygen (the concentration of ozone is 15% by volume) as an oxidant, cyclohexanol, ozone and solvent acetone are fed in at a molar ratio of 1:1:1. The reaction was carried out in an autoclave. Reaction for 2 hours: the conversion rate of cyclohexanol was 24%, the selectivity of cyclohexanone was 83%, and the selectivity of adipic acid was 6%.

Embodiment 2

[0038] At a temperature of 80°C and a pressure of 0.2 MPa, using a mixed gas of ozone and oxygen (the concentration of ozone is 5% by volume) as an oxidant, cyclohexanol, ozone and solvent methyl ethyl ketone are sent in a molar ratio of 1:2:10. into a high-pressure reactor for the reaction. Reaction for 2 hours: the conversion rate of cyclohexanol was 36%, the selectivity of cyclohexanone was 80%, and the selectivity of adipic acid was 8%.

Embodiment 3

[0040] At a temperature of 120°C and a pressure of 1.0MPa, using a mixed gas of ozone, carbon dioxide and oxygen (the concentration of ozone is 10% by volume, the rest being equal volumes of carbon dioxide and oxygen) as an oxidant, cyclohexanol, ozone and solvent acetone According to the molar ratio of 1:0.6:25, it is sent into the autoclave for reaction. Reaction for 3 hours: the conversion rate of cyclohexanol was 23%, the selectivity of cyclohexanone was 76%, and the selectivity of adipic acid was 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com