Preparation method of polynuclear metal phthalocyanine alkane oxidation catalyst

A technology for oxidation catalysts and phthalocyanine alkanes, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as high raw material costs and complicated preparation processes, Achieve the effects of low preparation cost, simplify the preparation process, and alleviate pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of polynuclear metal phthalocyanine is carried out according to the following steps: urea, phthalic anhydride or substituted phthalic anhydride, pyromellitic anhydride, and metal sources in a certain molar ratio are used as raw materials, and ammonium molybdate is used as a catalyst , with ammonium chloride as a synthetic additive, high-boiling alkanes, alkylbenzenes or their mixtures as solvents, liquid-phase reaction → suction filtration → boiling (distilled water, dilute acid, dilute alkali, etc.) → crude catalyst product → Soxhlet Extraction→drying→finished catalyst.

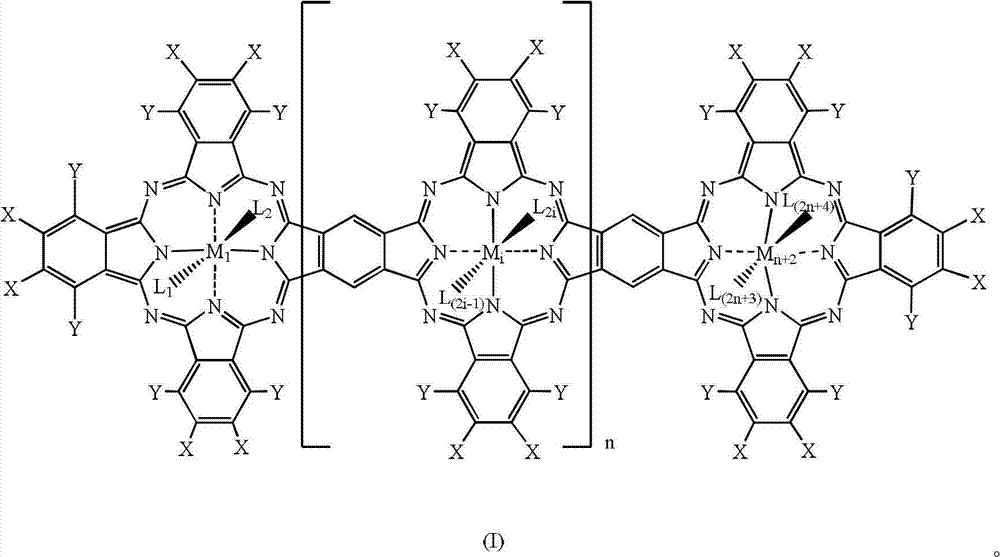

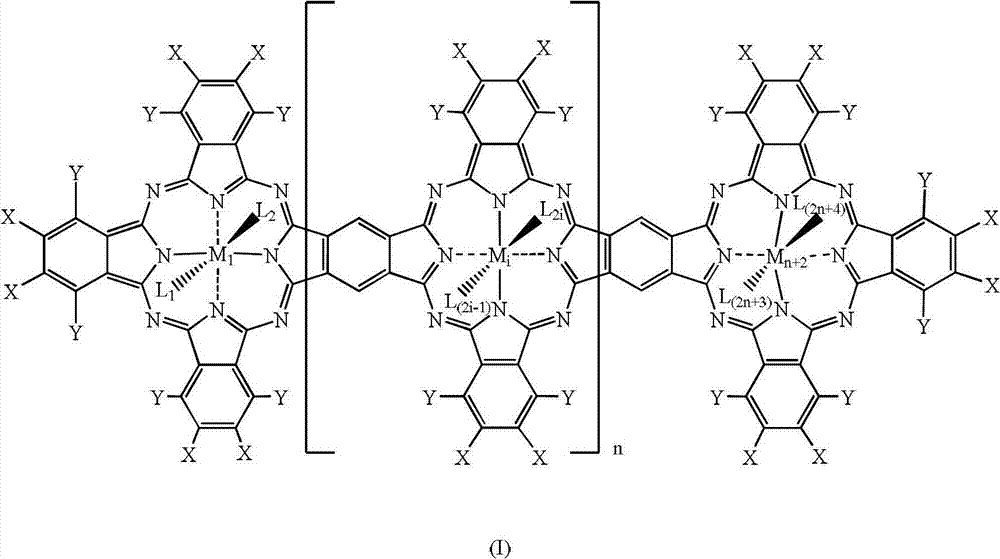

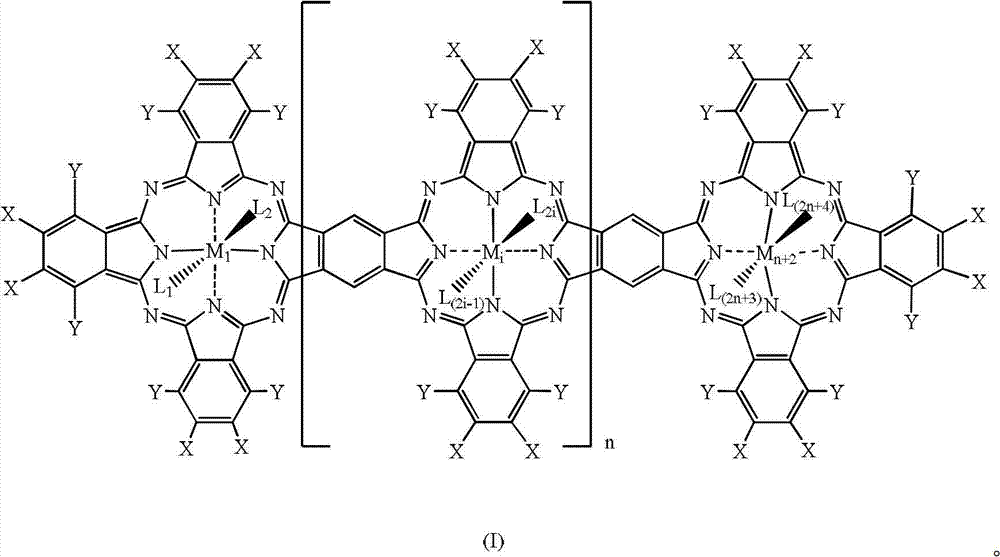

[0033] The structural general formula of above-mentioned polynuclear metal phthalocyanine is as shown in formula (I), wherein: n=0,1,2...; when n=0, i=none, when n≥1, i=2,3 ...(n+1), that is, all integers between 2 and (n+1); M is the metal as the active center; X is the peripheral substituent; Y is the non-peripheral substituent; L is the axial ligand .

[0034] The structura...

Embodiment 1

[0037] Binuclear iron-iron phthalocyanine alkane oxidation catalyst (general structural formula is shown in formula (I), wherein, n=0; M 1 = M 2 =Fe;X=Y=H,H;L 1 ~ L 4 = none) is prepared in the following steps:

[0038] Step 1: Mix 15g of phthalic anhydride, 19g of urea, 3.7g of tetrahydrate and ferrous chloride, 2.7g of pyromellitic anhydride, 0.5g of ammonium molybdate catalyst, 2.1g of ammonium chloride additive and grind them evenly , Add 100ml decahydronaphthalene solvent to obtain a reaction mixture. Firstly, the temperature of the reaction mixture was raised to 150° C., reacted for 30 minutes, then raised to the boiling point of the solvent, maintained at the boiling point for 4 hours, and then cooled to 80° C. to obtain a product mixture.

[0039] The second step: the product mixture is suction filtered, and the solvent is recovered to obtain a primary filter cake. Boil the primary filter cake with distilled water, dilute hydrochloric acid, and dilute NaOH solutio...

Embodiment 2

[0042] Trinuclear iron-iron-iron phthalocyanine alkane oxidation catalyst (structure general formula is shown in formula (I), wherein, n=1; M 1 = M 2 = M 3 =Fe;X=Y=H,H;L 1 ~ L 6 = none) is prepared in the following steps:

[0043] Step 1: Mix 18g of phthalic anhydride, 29g of urea, 5.6g of tetrahydrate and ferrous chloride, 5.4g of pyromellitic anhydride, 0.8g of ammonium molybdate catalyst, 2.1g of ammonium chloride additive and grind them evenly , Add 100ml decahydronaphthalene solvent to obtain a reaction mixture. Firstly, the temperature of the reaction mixture was raised to 150° C., reacted for 30 minutes, then raised to the boiling point of the solvent, maintained at the boiling point for 4 hours, and then cooled to 80° C. to obtain a product mixture.

[0044] The second step: the product mixture is suction filtered, and the solvent is recovered to obtain a primary filter cake. Boil the primary filter cake with distilled water, dilute hydrochloric acid, and dilute ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com