High-flame-retardance composite polyether used in fishing vessels

A technology combining polyether and flame-retardant polyether, which is applied in the field of polyurethane foam, can solve problems such as difficult control of production process, decline in physical and mechanical properties, and unstable product quality, so as to achieve good flame-retardant and fire-proof performance and reduce potential risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

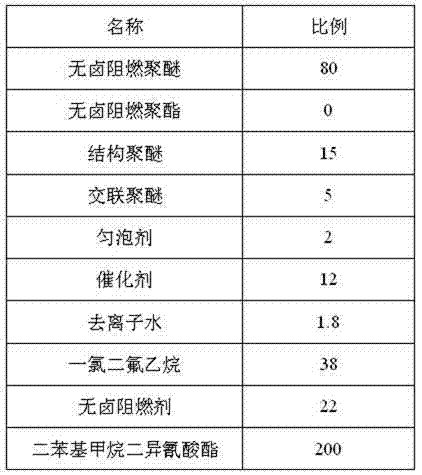

[0045] The high flame-retardant combined polyether for fishing boats in this example was prepared according to the following components and mass percentages, see Table 1 for details.

[0046] Table 1 The components and corresponding proportions of high flame retardant combined polyether for fishing boats

[0047]

[0048] Among them, the catalyst is pentamethyldiethylenetriamine (PC5), organotin (T12), potassium acetate (PC46), tris(dimethylaminopropyl) hexahydrotriazine (PC41) according to the ratio of 1:1:1:1 The mass ratio is obtained by compounding.

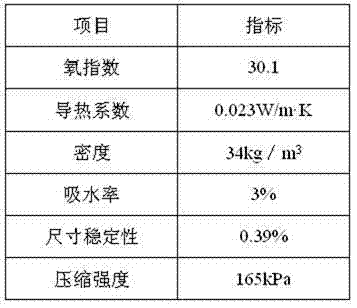

[0049] The performance of the high flame-retardant combined polyether for fishing boats prepared in this example was tested, and the results are shown in Table 2.

[0050] Table 2 Properties of high flame retardant combined polyether for fishing boats

[0051]

Embodiment 2

[0053] The high flame-retardant combined polyether for fishing boats in this example was prepared according to the following components and mass percentages, see Table 3 for details.

[0054] Table 3 Components and corresponding proportions of high flame retardant combined polyether for fishing boats

[0055]

[0056] Among them, the catalyst is pentamethyldiethylenetriamine (PC5), organotin (T12), potassium acetate (PC46), tris(dimethylaminopropyl) hexahydrotriazine (PC41) according to 1:0.5:1:0.5 The mass ratio is obtained by compounding.

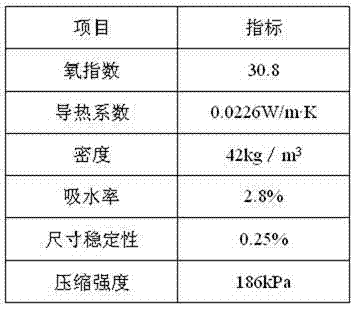

[0057] The performance of the high flame-retardant combined polyether for fishing boats prepared in this example was tested, and the results are shown in Table 4.

[0058] Table 4 Properties of high flame retardant combined polyether for fishing boats

[0059]

Embodiment 3

[0061] The high flame-retardant combined polyether for fishing boats in this example was prepared according to the following components and mass percentages, see Table 5 for details.

[0062] Table 5 Components and corresponding proportions of high flame retardant combined polyether for fishing boats

[0063]

[0064] Among them, the catalyst is pentamethyldiethylenetriamine (PC5), organotin (T12), potassium acetate (PC46), tris (dimethylaminopropyl) hexahydrotriazine (PC41) according to 0.5:2:0.5:2 The mass ratio is obtained by compounding.

[0065] The performance of the high flame-retardant combined polyether for fishing boats prepared in this example was tested, and the results are shown in Table 6.

[0066] Table 6 Properties of high flame retardant combined polyether for fishing vessels

[0067]

[0068]It can be seen from the above examples that the high flame-retardant combined polyether polyether for fishing vessels prepared by the technical scheme of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com