Solar battery backplane and preparation method thereof

A solar cell and backplane technology, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve problems such as insufficient bonding strength, difficult bonding, and low surface energy, and achieve novel structures and simplified production processes , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

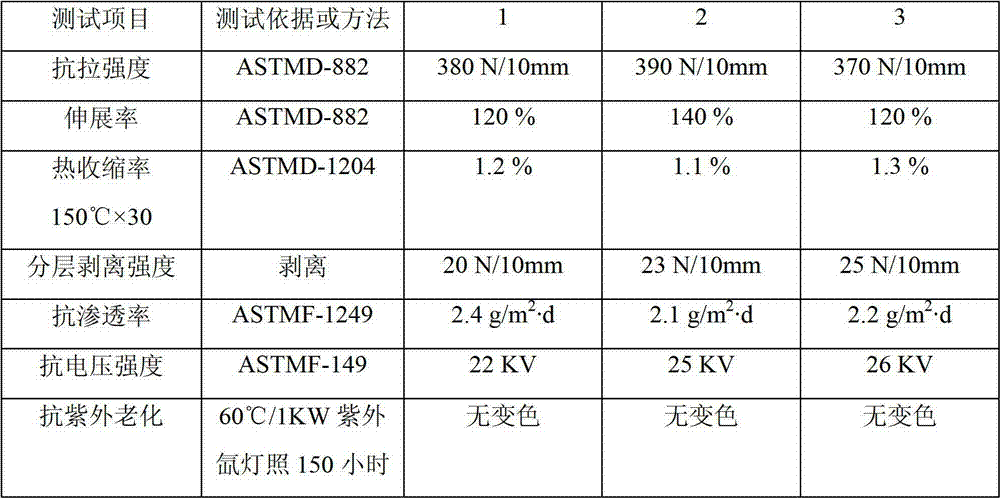

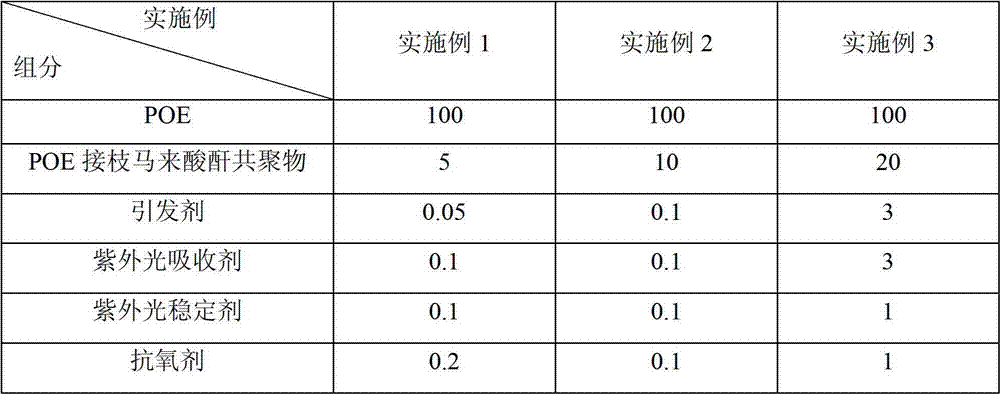

[0060] A layer of POE adhesive film is hot-pressed on the surface of the hydrolysis-resistant PET film to obtain a composite film for a solar cell back sheet.

[0061] The prepared solar battery back sheet film is composed of two layers of materials: a 500 micron thick PET film and a 500 micron thick POE adhesive film. The POE film layer is composed of the following components in parts by weight: 100 parts of POE resin, 5 parts of POE grafted maleic anhydride copolymer, 0.05 part of initiator dicumyl peroxide, 2 parts of ultraviolet light absorber -Hydroxy-4-methoxybenzophenone 0.1 part, UV light stabilizer bis(1-octyloxy-2,2,6,6-tetramethyl-4-piperidinyl) sebacate 0.1 0.2 parts of antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) stearyl propionate. The preparation method of POE film is as follows: mix the raw materials evenly and put them into the extruder for kneading. The temperature of the extruder is controlled at 60°C. Carry out shaping, and finally go through the win...

Embodiment 2

[0063] A layer of POE adhesive film is hot-pressed on the surface of the hydrolysis-resistant PET film to obtain a composite film for a solar cell back sheet.

[0064] The obtained solar battery back sheet film is composed of the following two layers of materials: a 500 micron thick PET film and a 500 micron thick POE adhesive film. The POE film layer is composed of the following components in parts by weight: 100 parts of POE resin, 10 parts of POE grafted maleic anhydride copolymer, 0.1 part of initiator dicumyl peroxide, 2 parts of ultraviolet light absorber -Hydroxy-4-n-octyloxybenzophenone 0.1 part, UV light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate 0.1 part, antioxidant β -0.1 part of stearyl (3,5-di-tert-butyl-4-hydroxyphenyl)propionate. The preparation method of POE film is as follows: mix all the raw materials evenly and put them into the extruder for kneading. The temperature of the extruder is controlled at 150°C. Carry out shaping, and finally go...

Embodiment 3

[0066] A layer of POE adhesive film is hot-pressed on the surface of the hydrolysis-resistant PET film to obtain a composite film for a solar cell back sheet. The obtained solar battery back sheet film is composed of the following two layers of materials: a PET film with a thickness of 500 microns and a POE adhesive film with a thickness of 400 microns. The POE film layer is composed of the following components in parts by weight: 100 parts of POE resin, 20 parts of POE grafted maleic anhydride copolymer, 3 parts of initiator dicumyl peroxide, 2 parts of ultraviolet light absorber - 3 parts of hydroxy-4-methoxybenzophenone, 1 part of bis(2,2,6,6-tetramethyl-4 piperidinyl) sebacate of UV light stabilizer, 1 part of antioxidant tri( 1 part of 2,4-di-tert-butylphenol) phosphite. The preparation method of POE film is as follows: mix all the raw materials evenly and put them into the extruder for kneading. The temperature of the extruder is controlled at 120°C. Carry out shaping,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com