Production method of Sublancin antibacterial peptide

A production method and antimicrobial peptide technology are applied in the production field of Sublancin antimicrobial peptides to achieve the effects of expanding fermentation scale, easy popularization and application, and excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

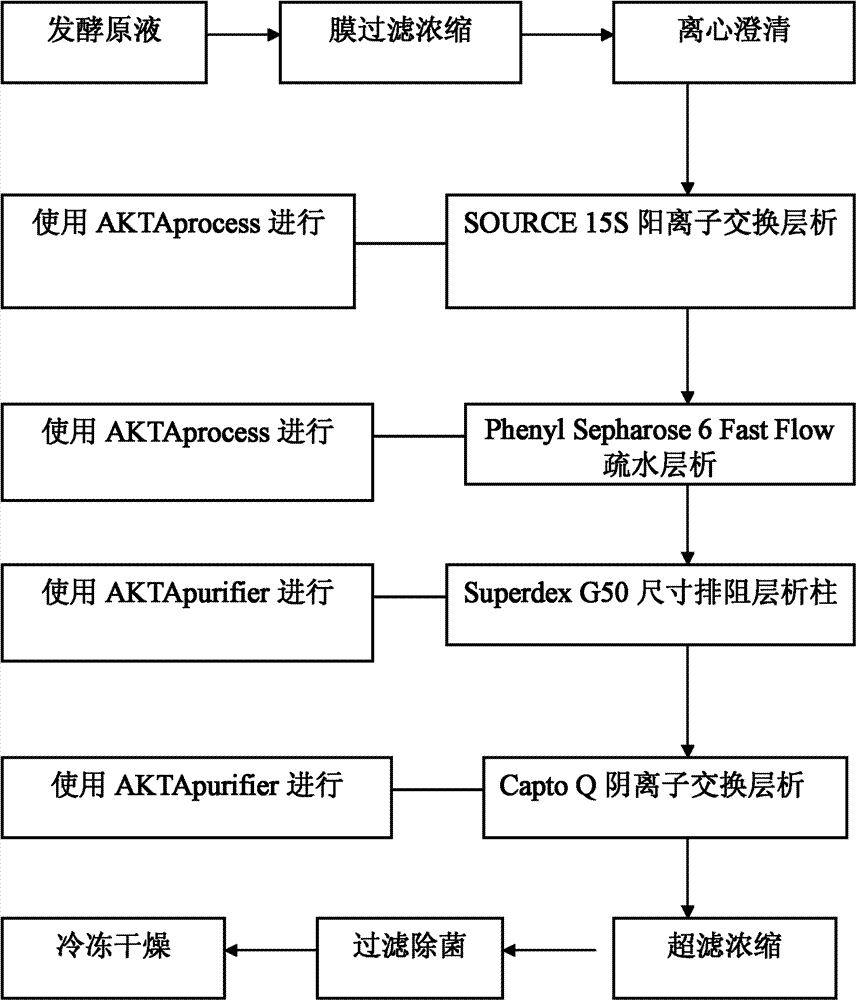

Method used

Image

Examples

Embodiment 1

[0043] Fermentation scale: 10m 3 . 1L of fermentation medium contains: 20g of corn flour, 20g of soybean meal, 5g of peptone, 5g of glucose, 5g of ammonium sulfate, and 0.8g of magnesium sulfate. Adjust the pH to 7.5 with sodium hydroxide. The culture solution was sterilized by temperature of 121°C, tank pressure of 0.08Mpa, and holding time of 30min. Bacillus subtilis B. subtilis CVCC20076 was purchased from China Industrial Microorganism Culture Collection Management Center. The inoculum amount of the bacteria was 1×10 6 CFU / mL. Fermentation temperature: 34°C, ventilation: 600m 3 / h, stirring speed: 120r / min, pH7.0. Fermentation culture time: 32h. The membrane pore diameter of ceramic membrane filtration is 20nm to obtain the fermentation broth of Sublacin antimicrobial peptide.

Embodiment 2

[0045] Fermentation scale: 20m 3 . 1L of fermentation medium contains: 50g of corn flour, 50g of soybean meal, 20g of peptone, 20g of glucose, 5g of ammonium sulfate, 5g of yeast powder, and 5g of dipotassium hydrogen phosphate. Adjust the pH to 8.0 with sodium hydroxide. The culture solution is sterilized by a temperature of 121°C, a tank pressure of 0.15Mpa, and a holding time of 30 minutes. The inoculum amount of Bacillus subtilis CVCC20076 was 1×10 7 CFU / mL. Fermentation temperature: 30°C, ventilation: 1000m 3 / h, stirring speed: 160r / min, pH: 6.5. Fermentation culture time: 24h. The membrane pore diameter of ceramic membrane filtration is 10nm to obtain the fermentation broth of Sublacin antimicrobial peptide.

Embodiment 3

[0047] Fermentation scale: 10m 3 . 1L of fermentation medium contains: 10g of corn flour, 10g of soybean meal, 5g of peptone, 2g of sucrose, and 5g of ammonium sulfate. Adjust the pH to 7.0 with sodium hydroxide. The culture solution is sterilized by temperature of 121°C, tank pressure of 0.10Mpa, and holding time of 30 minutes. The inoculum amount of Bacillus subtilis CVCC20076 was 1×10 6 CFU / mL. Fermentation temperature: 37°C, ventilation: 720m 3 / h, stirring speed: 200r / min, pH: 6.0. Fermentation culture time: 28h. The membrane pore diameter of ceramic membrane filtration is 30nm to obtain the fermentation broth of Sublacin antimicrobial peptide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com