Sugarcane leaf briquetting feed for cattle and sheep and preparation method thereof

A sugarcane leaf and feed technology, applied in animal feed, animal feed, application, etc., can solve the problems of inconvenient storage and low nutritional value, and achieve the effect of low cost, high nutritional value and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

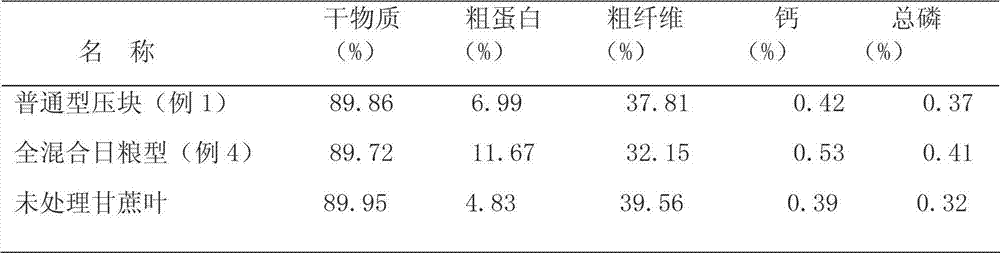

Examples

Embodiment 1

[0025] Example 1 (common briquette feed for cattle and sheep)

[0026] 1. Raw material composition and parts by weight:

[0027] Sugarcane leaves (water 65%) 1000 kg; urea 30 kg; salt 5 kg; sodium bicarbonate 5 kg; molasses 9 kg; Lactobacillus 0.004 kg; Bacillus subtilis 0.002 kg; Bacillus licheniformis 0.002 kg; 100 kg of water.

[0028] 2. Preparation method:

[0029] Firstly, the harvested fresh sugarcane leaves are crushed with a machine, shortened to 4-5cm long, and then cooled to adjust the water content to 65%. Before processing the sugarcane leaves, add 0.20-0.25 kg of water and 0.09 kg of molasses to the lactobacillus, bacillus subtilis, bacillus licheniformis and yeast, stir to fully dissolve, ferment at room temperature for 3 hours to revive live and dried bacteria, and obtain microbial preparations for use. Dissolve microbial preparations, urea, salt, sodium bicarbonate and molasses in water, stir and spray evenly on sugarcane leaves. Finally, the treated sugar...

Embodiment 2

[0030] Example 2 (common briquette feed for cattle and sheep)

[0031] 1. Raw material composition and parts by weight:

[0032] Sugarcane leaves (moisture 40%) 1000 kg; urea 29 kg; salt 4.5 kg; sodium bicarbonate 4.5 kg; molasses 10 kg; lactobacillus 0.004 kg; 150 kg of water.

[0033] 2. Preparation method:

[0034] Firstly, the harvested fresh sugarcane leaves are crushed with a machine, shortened to a length of 3-4cm, and then cooled to adjust the water content to within 40%. Before processing the sugarcane leaves, add 0.20-0.25 kg of water and 0.09 kg of molasses to the lactobacillus, bacillus subtilis, bacillus licheniformis and saccharomyces to dissolve fully, and ferment at room temperature for 2.5 hours to revive live and dried bacteria to obtain microbial preparations for use. Dissolve microbial preparations, urea, salt, sodium bicarbonate and molasses in water, stir and spray evenly on sugarcane leaves. Finally, the treated sugarcane leaves are loaded into a bal...

Embodiment 3

[0035] Example 3 (common briquette feed for cattle and sheep)

[0036]1. Raw material composition and parts by weight:

[0037] Sugarcane leaves (water 60%) 900 kg; urea 28 kg; salt 4 kg; sodium bicarbonate 4 kg; molasses 8 kg; Lactobacillus 0.004 kg; Bacillus subtilis 0.002 kg; Bacillus licheniformis 0.002 kg; 120 kg of water.

[0038] 2. Preparation method:

[0039] Firstly, the harvested fresh sugarcane leaves are crushed with a machine, shortened to a length of 4-5cm, and then cooled to adjust the water content to within 60%. Before processing the sugarcane leaves, add 0.20-0.25 kg of water and 0.09 kg of molasses to the lactobacillus, bacillus subtilis, bacillus licheniformis and yeast, stir to fully dissolve, ferment at room temperature for 2-4 hours to revive live and dried bacteria, and obtain microbial preparations for use. Dissolve microbial preparations, urea, salt, sodium bicarbonate and molasses in water, stir and spray evenly on sugarcane leaves. Finally, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com