Preparation method of copper sulfide ultra-long micro-wire

A technology of micron wire and copper sulfide, applied in copper sulfide, nanotechnology, nanotechnology and other directions, can solve the problems of serious environmental pollution, difficult to control conditions, complex synthesis process, etc., and achieve low environmental pollution, low cost, and simplified process steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

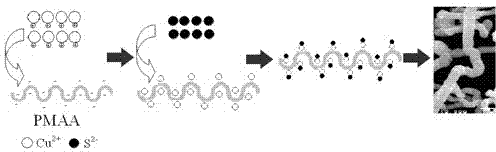

[0017] 0.2496g CuSO 4 ·5H 2 O was dissolved in 100ml of distilled water, then 0.01g of PMAA was added, stirred at room temperature for 30min until completely dissolved, and then the solution was placed in a vacuum oven at 80°C for 2h. The solution was removed, and 0.076 g of CH was added to it 4 N 2 S, after stirring for 10 min, the solution was placed in a vacuum oven at 80° C. for 24 h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was repeatedly washed with deionized water and absolute ethanol, and finally dried under vacuum at 60°C for 12 hours to obtain a black product.

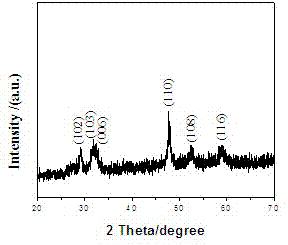

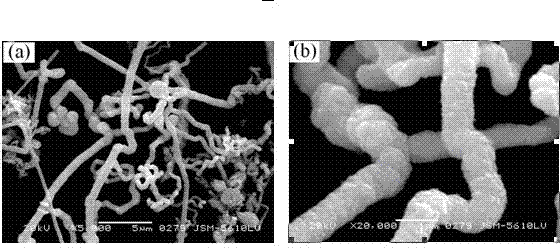

[0018] figure 1 XRD patterns of CuS microwires synthesized by template method. from figure 1 It can be seen that all the XRD peak positions in the figure are consistent with the standard diffraction pattern (JCPDS No.0620464), and there are no other miscellaneous peaks, indicating that the reaction product is pure CuS hexagonal crystal without Cu 2 ...

Embodiment 2

[0021] 0.2496g CuSO 4 ·5H 2 O was dissolved in 100ml of distilled water, then 0.01g of PEG600 was added, stirred at room temperature for 30 minutes until completely dissolved, and then the solution was kept in a vacuum oven at 80°C for 2 hours. The solution was removed, and 0.076 g of CH was added to it 4 N 2 S, after stirring for 10 min, the solution was placed in a vacuum oven at 80° C. for 24 h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was repeatedly washed with deionized water and absolute ethanol, and finally dried under vacuum at 60° C. for 12 hours to obtain a black product.

Embodiment 3

[0023] 0.2496g CuSO 4 ·5H 2 O was dissolved in 100ml of distilled water, then 0.01g of PAA was added, stirred at room temperature for 30min until completely dissolved, and the solution was placed in a vacuum oven at 80°C for 2h. The solution was removed, and 0.076 g of CH was added to it 4 N 2 S, after stirring for 10 min, the solution was placed in a vacuum oven at 80° C. for 24 h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was repeatedly washed with deionized water and absolute ethanol, and finally dried under vacuum at 60° C. for 12 hours to obtain a black product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com