Process for synthesizing triamcinolone acetonide acetate

A technology of triamcinolone acetonide acetate and a synthetic method, which is applied in the field of pharmaceutical chemical synthesis, can solve problems such as no synthetic technology of triamcinolone acetonide acetate, and achieve the effects of low toxicity, low risk, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

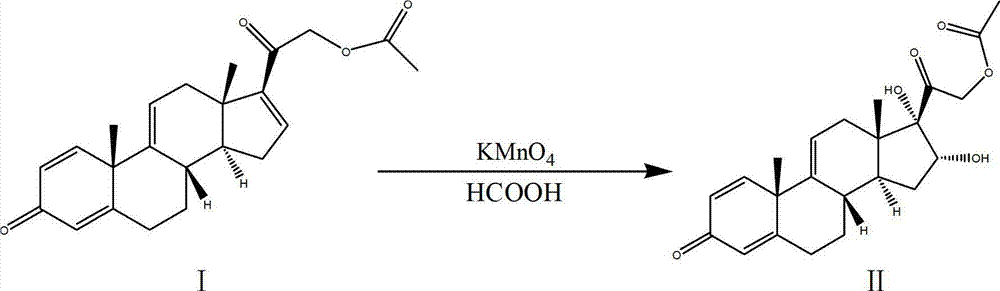

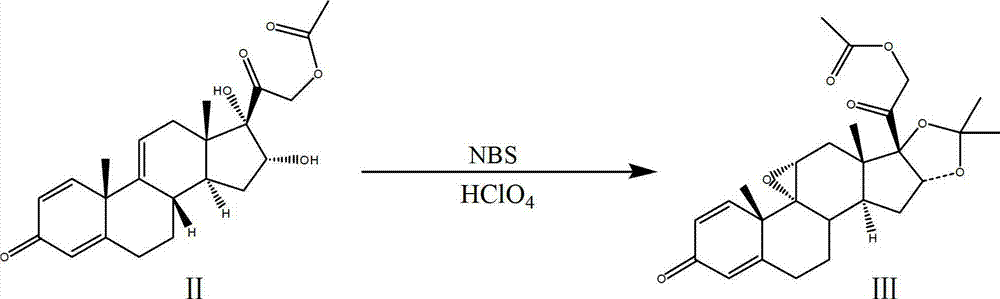

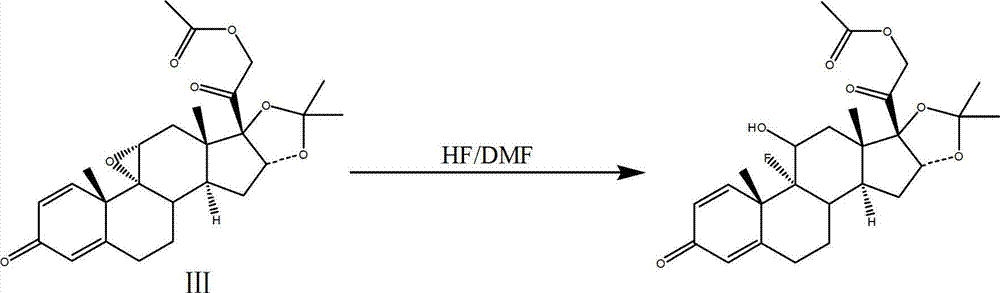

[0032] Step 1, take tetraenyl acetate as raw material, obtain oxide compound through oxidation reaction under the effect of formic acid and potassium permanganate, concrete process is:

[0033] 101. Add 20g tetraenyl acetate and 640mL reaction solvent acetone into the reactor, cool down to 0°C, then add 6mL formic acid into the reactor, stir for 15min, then add 150mL potassium permanganate solution into the reactor, stir for 6min Then add 100mL reducing solution (sodium sulfite aqueous solution with a concentration of 100g / L) to the reactor, stir and react for 10min, heat up the reaction system in the reactor to 38°C and filter to obtain filter cake and filtrate; the permanganic acid The potassium solution is a mixed solution of potassium permanganate, acetone and water, wherein the concentration of potassium permanganate is 65g / L, and the volume ratio of acetone and water is 1:14;

[0034] 102. Concentrate the filtrate described in 101 under reduced pressure until there is no...

Embodiment 2

[0044] Step 1, take tetraenyl acetate as raw material, obtain oxide compound through oxidation reaction under the effect of formic acid and potassium permanganate, concrete process is:

[0045] 101. Add 20g tetraenyl acetate and 600mL reaction solvent acetone into the reactor, cool down to -3°C, then add 5.7mL formic acid into the reactor, stir for 10min, then add 190mL potassium permanganate solution into the reactor, stir After reacting for 4 minutes, add 96 mL of reducing solution (sodium sulfite aqueous solution with a concentration of 80 g / L) to the reactor, stir and react for 5 minutes, heat up the reaction system in the reactor to 35 ° C and filter to obtain a filter cake and filtrate; Potassium manganate solution is a mixed solution of potassium permanganate, acetone and water, wherein the concentration of potassium permanganate is 50g / L, and the volume ratio of acetone and water is 1:12;

[0046] 102. Concentrate the filtrate described in 101 under reduced pressure un...

Embodiment 3

[0056] Step 1, take tetraenyl acetate as raw material, obtain oxide compound through oxidation reaction under the effect of formic acid and potassium permanganate:

[0057] 101. Add 20g tetraenyl acetate and 680mL reaction solvent acetone into the reactor, cool down to 6°C, then add 6.1mL formic acid into the reactor, stir for 20min, then add 148mL potassium permanganate solution into the reactor, and stir to react After 8 minutes, 110 mL of reducing solution (sodium sulfite aqueous solution with a concentration of 120 g / L) was added to the reactor, stirred for 15 minutes, and the reaction system in the reactor was heated to 40 ° C and then filtered to obtain a filter cake and filtrate; the high manganese The potassium permanganate solution is a mixed solution of potassium permanganate, acetone and water, wherein the concentration of potassium permanganate is 70g / L, and the volume ratio of acetone and water is 1:16;

[0058] 102. Concentrate the filtrate described in 101 under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com