Processing method for solubilizing and modifying rice bran protein

A processing method and rice bran protein technology are applied in the directions of protein food processing, vegetable protein processing, protein food ingredients, etc., which can solve the problems of loss of nutrients, difficult moisture content of rice bran, consumption of a lot of electricity, etc., so as to increase the content of rice bran protein and avoid A large amount of loss, the effect of maintaining nutritional quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Stabilization of rice bran: Pass the newly produced rice bran through a 40-mesh sieve to remove impurities, and then ultrafinely pulverize it for 20 minutes, so that the pulverized rice bran particles can pass through a 400-mesh sieve. The extremely fine rice bran particles are heated by microwave for a short time on the production line, and the rice bran particles are spread on the conveyor belt with a thickness of no more than 0.5 cm. The microwave power is 0.8kw, and the passing time of the conveyor belt is adjusted to 120 seconds. Seal the rice bran after the inactivated enzyme is heated by microwave for a short time with a plastic bag, and store it at room temperature in a dry, cool and ventilated environment.

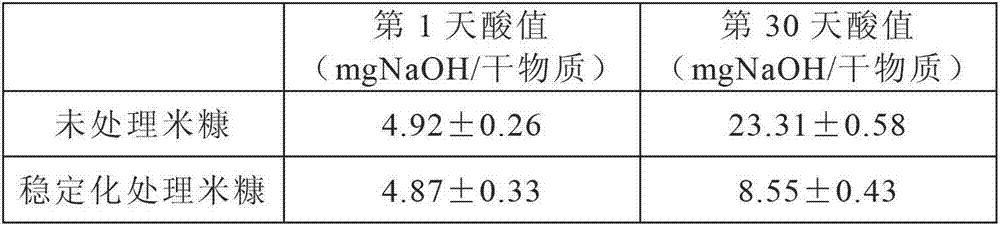

[0021] The rice bran without any treatment was compared with the above stabilized rice bran. During the storage period of 30 days, the acid value change of rice bran was measured according to the method of ISO7305:1998. The change in acid value in the ...

Embodiment 2

[0028] (1) Stabilization of rice bran: Pass the newly produced rice bran through a 40-mesh sieve to remove impurities, and then ultrafinely pulverize it for 10 minutes, so that the crushed rice bran particles can pass through a 300-mesh sieve. The extremely fine rice bran particles are heated through the production line by microwave for a short time, and the rice bran particles are spread flat on the conveyor belt with a thickness of no more than 0.8 cm. The microwave power is 1.0kw, and the passing time of the conveyor belt is adjusted to 90 seconds. Seal the rice bran after the inactivated enzyme is heated by microwave for a short time with a plastic bag, and store it at room temperature in a dry, cool and ventilated environment.

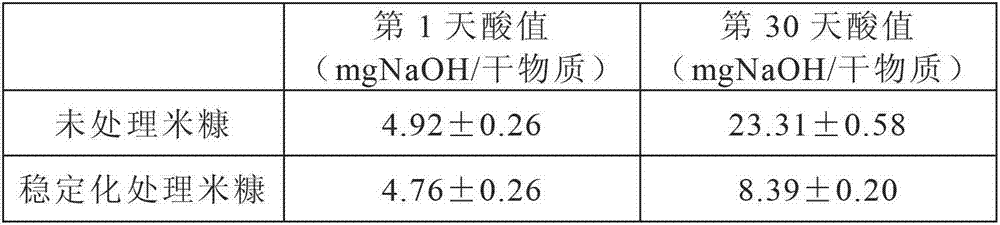

[0029] The rice bran without any treatment was compared with the above stabilized rice bran. During the storage period of 30 days, the acid value change of rice bran was measured according to the method of ISO7305:1998. The change in acid value i...

Embodiment 3

[0036] (1) Stabilization of rice bran: Pass the newly produced rice bran through a 40-mesh sieve to remove impurities, and then ultrafinely pulverize it for 30 minutes, so that the pulverized rice bran particles can pass through a 200-mesh sieve. The extremely fine rice bran particles are heated through the production line by microwave for a short time, and the rice bran particles are spread on the conveyor belt with a thickness of no more than 1.0 cm. The microwave power is 1.2kw, and the passing time of the conveyor belt is adjusted to 60 seconds. Seal the rice bran after the inactivated enzyme is heated by microwave for a short time with a plastic bag, and store it at room temperature in a dry, cool and ventilated environment.

[0037] The rice bran without any treatment was compared with the above stabilized rice bran. During the storage period of 30 days, the acid value change of rice bran was measured according to the method of ISO7305:1998. The change in acid value in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com