Method for preparing fusiform complicated organ precursor by using rotary assembling die

A combined mold and spindle-shaped technology is used in the field of preparing tissue and organ precursors by using synthetic polymer materials and cell matrix materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

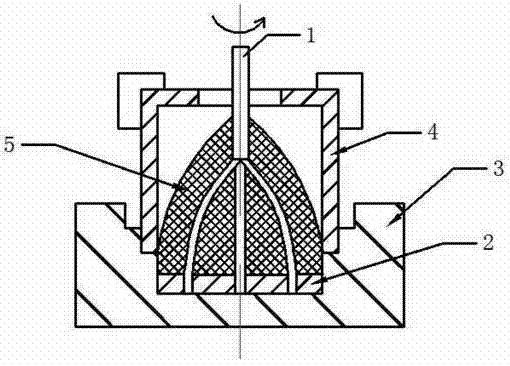

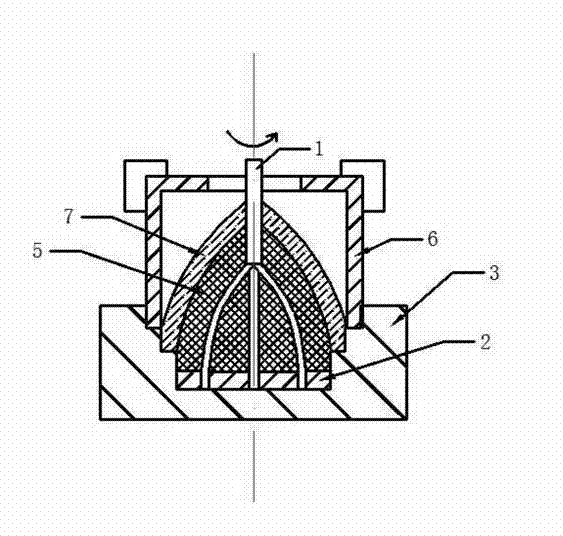

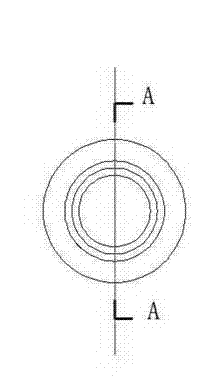

Embodiment 1

[0051] 1) Use brass to prepare the bottom mold with three steps, the inner ring mold and the outer ring mold, and nylon to prepare the inner mold with first-level branches; 2) Prepare 1% fibrinogen solution, and insert the bottom of the inner mold into the base mold In the array orifice plate, the array orifice plate is embedded in the bottom of the base mould, the first-level inner ring mold is placed on the first step of the base mould, and fibrinogen and endothelium are injected between the inner mold and the first-level inner ring mould. Mixture of cells at a cell density of 1 x 10 7 cells / mL, make the base mold, inner mold and array well plate rotate together (the speed is 5r / min) and keep the first-stage inner ring mold still, so that the cell matrix solution forms a semi-spindle shape, and use coagulation during the rotation Soak the formed product in enzyme solution (20IU / mL) for 2 minutes to polymerize, remove the first-level inner ring mold, and form a stable first l...

Embodiment 2

[0052] Example 2: (1) Prepare the bottom mold with four steps, the inner ring mold and the outer ring mold with silicon rubber, and prepare the inner mold with secondary branches with polyethylene; (2) prepare 5% fibrinogen solution, Insert the bottom of the inner mold into the array orifice plate of the base mould, the array orifice plate is embedded in the bottom of the base mold, put the first-level inner ring mold on the first step of the base mold, and the inner mold and the first-level inner ring mold Fibrinogen / endothelial cell mixture containing 1% paclitaxel (cell density 1×10 7 pcs / mL), the base mold, the inner mold and the array plate are rotated together (rotating speed is 10r / min) and the first-stage inner ring mold is kept still, so that the cell matrix solution forms a semi-spindle shape, during the rotation process, use Soak the formed product in thrombin solution (10IU / mL) for 1 minute to polymerize, remove the first-level inner ring mold, and form a stable fi...

Embodiment 3

[0053] Example 3: (1) Use polytetrafluoroethylene to prepare a bottom mold with five steps, an inner ring mold and an outer ring mold, and polyurethane to prepare an inner mold with three-level branches; (2) prepare a 10% collagen solution, and The bottom of the inner mold is inserted into the array hole plate of the base mold, the array hole plate is embedded in the bottom layer of the base mold, the first-level inner ring mold is set on the first step of the base mold, and then 1% sodium citrate collagen / endothelial Cell mixture (cell density is 1 x 10 7per mL) into the gap between the inner mold and the first-stage inner ring mold, so that the base mold, the inner mold and the array orifice plate rotate together (the speed is 20r / min) and the first-stage inner ring mold remains constant Rotate to make the cell matrix solution form a semi-spindle shape. During the rotation process, use physical cross-linking method to place it at 37°C for 10 minutes to stabilize the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com