Plate-type membrane bioreactor, method for constructing same and method for purifying volatile organic waste gas

A technology of volatile organic compounds and bioreactors, applied in chemical instruments and methods, separation methods, membrane technology, etc., can solve problems such as exhaust with bioaerosols, unstable work and operation, secondary odor effects, etc., to achieve The effect of simple structure, small pressure drop, and easy engineering amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, flat-plate membrane bioreactor and its structure and using method

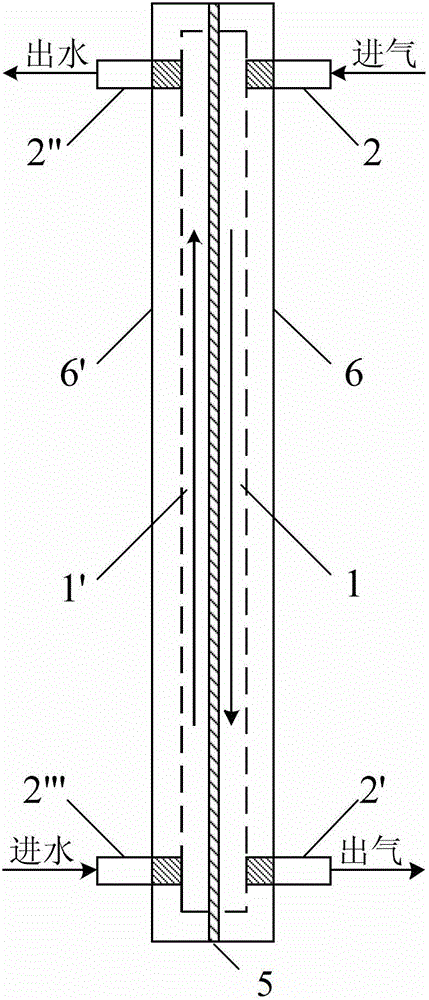

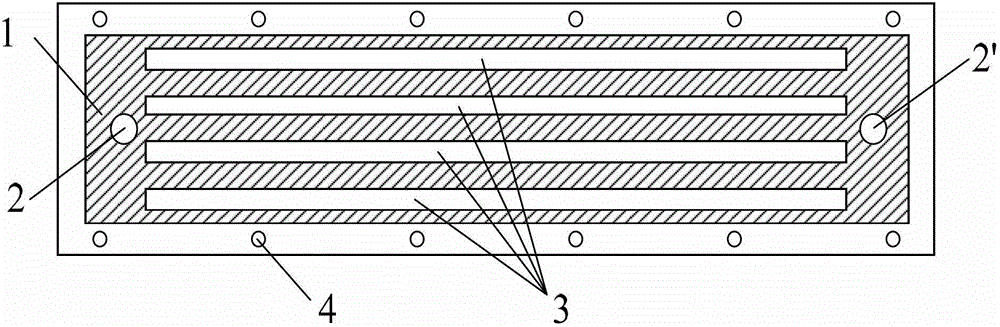

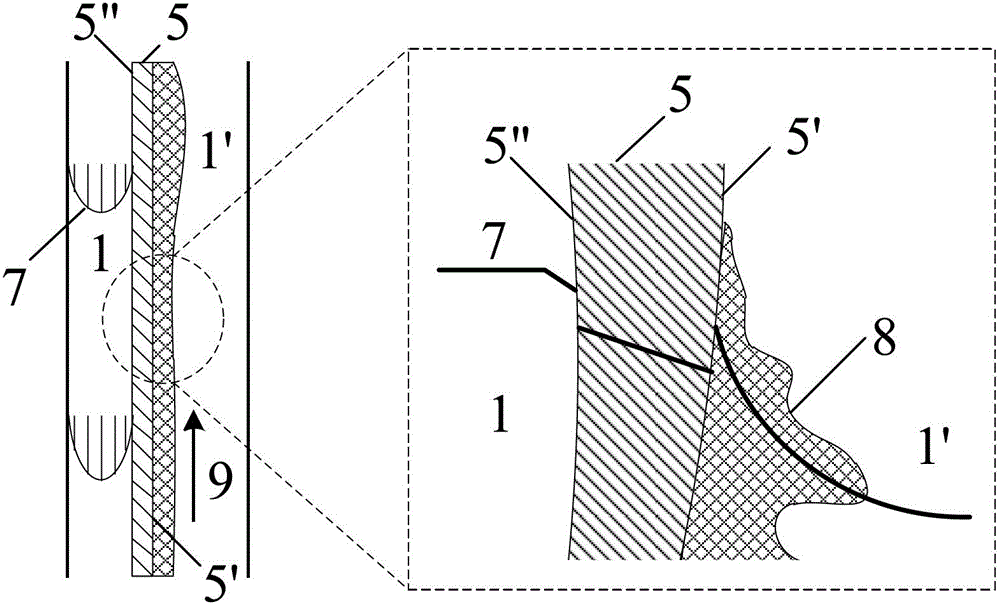

[0037] like Figure 1-3 As shown, the present invention provides a flat-plate membrane bioreactor for the purification of volatile organic waste gas, specifically as figure 1 shown. The flat-panel membrane bioreactor mainly comprises: parallel flat plates 6 and 6', and a flat film 5 fixed in parallel between the two flat plates; flat plates 6 and 6' have a rectangular shape on opposite sides Grooves are respectively formed into two closed areas 1 and 1' under the action of the interval of the flat film 5, and a layer of active biofilm 8 is attached and grown on the side of the flat film 5 facing the closed area 1', and the upper surface of the outer side of the flat plate 6 is , lower end have air inlet 2 and air outlet 2 ' respectively, and the upper and lower ends of the outside of plate 6 ' have water outlet 2 " and water inlet 2 ' " respectively, and these inlets and outlets commun...

Embodiment 2

[0046] Embodiment 2, the concentration analysis of volatile organic compound

[0047] Gases such as benzene series, alkyd esters, aldehydes and ketones, and alkenynes in volatile organic compounds are analyzed by gas chromatography. For the treatment of membrane bioreactor, samples are taken at various time points, and the treatment efficiency is calculated according to the different inlet and outlet concentrations of different pollutants, and the curve is drawn according to the calculation results. The results are shown in Figure 4-7 .

[0048] The calculation formula of processing rate is: [(C in -C out ) / C in ]×100%

[0049] 2.1 Benzene series

[0050] Chromatographic column: PEG20M cross-linked column, 19m×0.25mm;

[0051] Column temperature: 40°C;

[0052] Carrier gas: N 2 ;

[0053] Peak order: 1) benzene, 2) toluene, 3) ethylbenzene, 4) p-xylene, 5) m-xylene, 6) o-xylene, 7) p-methylethylbenzene, 8) m-methyl Ethylbenzene, 9) o-methylethylbenzene.

[0054] ...

Embodiment 3

[0070] Embodiment 3, floor space comparison

[0071] Among the traditional biological methods for treating waste gas, the biological trickling filter has the widest applicability. Taking xylene as an example, the average removal capacity of biotrickling filter for xylene is 35g / (m 3 h), which represents the unit volume (l m 3 ) packing medium can degrade 35g of xylene pollutants per unit time (1h).

[0072] The present invention uses the flat membrane bioreactor to toluene removal capacity to be 0.2g / (m 2 h), assuming that the groove depth of the flat plate is 4mm, and the volume of the circulating active biological liquid is 3 times of the groove volume, so it takes about 0.68m to process 35g xylene in 1 hour 3 , less than 1m of traditional biological trickling filter 3 Filler volume, reduced by 31% volume.

[0073] This is due to the extremely thin thickness of the flat film, which is much smaller than the volume occupied by the filler, so the degradation capacity per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com